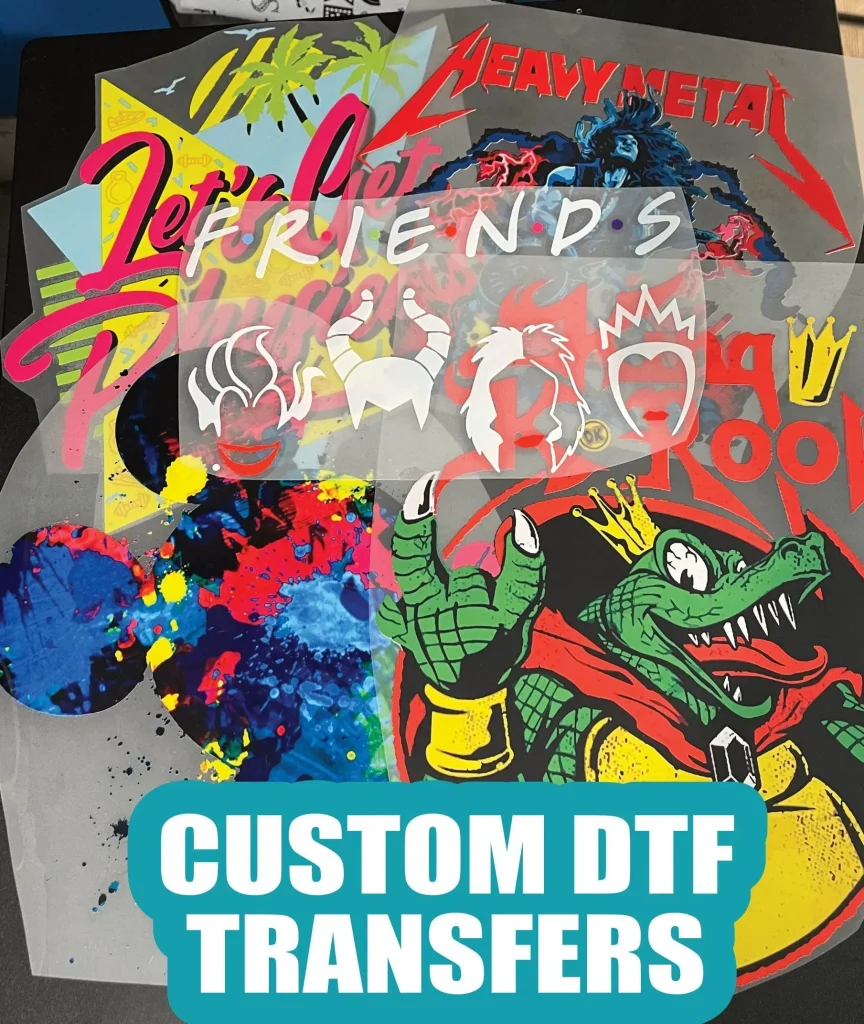

DTF Transfers, or Direct-to-Film transfers, are at the forefront of custom designs in apparel and fabric printing. This revolutionary technique allows users to create intricate, high-quality prints that can be applied to a wide range of materials, from cotton to polyester. Thanks to DTF printing, hobbyists and small business owners alike can achieve vibrant colors and remarkable durability with ease. The heat press transfer process involved ensures a strong bond between the print and the fabric, resulting in long-lasting designs. In this guide, we’ll explore how to effectively use DTF Transfers to bring your creative visions to life and elevate your apparel game.

Often referred to as film transfers or heat transfer films, DTF Transfers represent a cutting-edge solution for those interested in custom apparel and textile designs. This innovative method leverages the power of DTF printing to produce high-resolution, vivid images that can be transferred seamlessly onto various fabrics. The design transfer process is user-friendly, enabling both seasoned professionals and enthusiastic newcomers to produce stunning results. With the versatility of print on fabric applications extending to items like bags, t-shirts, and home textiles, the appeal of DTF printing continues to grow. As the demand for personalized clothing surges, understanding this technique will unlock new creative avenues for artists and entrepreneurs.

The Basics of DTF Printing: How Does It Work?

DTF printing, or Direct-to-Film printing, is a modern method that involves printing designs on a specialized PET (polyethylene terephthalate) film. The process begins with a DTF printer that uses high-quality inks to produce a vibrant design. After printing, a hot melt adhesive powder is applied to the wet ink and cured using heat. This preparation step is crucial as it prepares the design for a successful transfer onto various substrates, such as fabrics made of cotton or polyester. The entire process is becoming increasingly popular due to its efficiency and the stunning results it produces.

Once the design has been cured, it is heat pressed onto the fabric of choice. This involves placing the film on the fabric and applying a significant amount of heat and pressure for a specific duration, allowing the adhesive to bond seamlessly with the fibers of the fabric. The result is a striking and durable design that can withstand regular washing and wear, making this method highly desirable for custom apparel production.

Frequently Asked Questions

What are DTF transfers and how do they relate to custom designs?

DTF transfers, or Direct-to-Film transfers, are a printing method that allows for the creation of custom designs by printing high-resolution images onto a special PET film. This process is ideal for custom apparel as it produces vibrant colors and intricate details on various materials.

How do I print on fabric using DTF transfers?

To print on fabric using DTF transfers, you’ll need a DTF printer to print your design onto PET film, followed by applying hot melt adhesive powder. After curing the film, use a heat press to transfer the design onto the fabric, ensuring a strong and lasting bond.

What materials are needed for the DTF printing process?

For effective DTF printing, you will need a DTF printer, PET film, heat press machine, high-quality DTF inks, and hot melt adhesive powder. These materials are crucial for ensuring successful design transfer to fabric.

Can DTF transfers be used on different types of fabrics?

Yes, DTF transfers are versatile and can be applied to a wide range of fabrics including cotton, polyester, and blends. This flexibility makes them suitable for customizing various apparel items like t-shirts, hoodies, and bags.

What advantages do DTF transfers provide for custom apparel printing?

DTF transfers offer several advantages including vibrant color reproduction, durability against fading and cracking, ease of use for beginners, and the ability to print on multiple fabric types. These benefits make DTF a popular choice for custom designs.

What are the best practices for achieving optimal results with DTF printing?

To achieve optimal results with DTF printing, always ensure your heat press settings are matched to the fabric type, test transfers on scrap material first, and store your DTF inks and powders in a cool, dry place to maintain quality.

| Key Point | Description |

|---|---|

| Understanding DTF Transfers | DTF transfers are high-resolution prints on PET film, using a hot melt adhesive for heat pressing onto various fabrics. |

| Advantages | DTF transfers offer versatility, durability, and ease of use, suitable for various materials and ideal for beginners. |

| Equipment Needed | Essential equipment includes a DTF printer, heat press machine, PET film, and quality DTF inks and adhesive powder. |

| Step-by-Step Process | 1. Create and mirror your design. 2. Print on PET film. 3. Apply adhesive powder. 4. Heat press onto fabric. 5. Peel film after cooling. |

| Expert Tips | Check press settings for fabric type, test on scraps, and store materials properly for best results. |

| Current Trends | Innovations in DTF include better inks and eco-friendly materials, with a focus on customization for niche markets. |

Summary

DTF Transfers open up endless possibilities for creating high-quality custom designs that resonate with consumers. This innovative printing method not only enhances the artistic capabilities of designers but also streamlines the application process for hobbyists and professionals alike. With its remarkable durability and versatility, DTF Transfers enable the production of vibrant, long-lasting prints on a variety of fabrics. In a landscape increasingly driven by personalization and innovation, embracing DTF Transfers is a timely investment that can elevate your design projects and fulfill the growing demand for unique, customized apparel.