The **DTF Transfer Process** has emerged as a leading technique in the realm of garment decoration, capturing the interest of both professionals and DIY enthusiasts alike. This innovative approach leverages Direct-to-Film printing technology to seamlessly transfer vibrant designs onto fabric, ensuring durability and flexibility in application. With its eco-friendly options and high-quality results, DTF printing caters perfectly to the growing desire for customized and unique garments. By following the step-by-step DTF transfer application process, individuals can create stunning custom apparel that not only showcases personal style but also adheres to sustainable practices. Explore more about the intricacies of DTF printing and discover why it’s rapidly becoming the preferred choice for garment decoration techniques.

Direct-to-Film (DTF) transfer techniques are revolutionizing how designs are applied to textiles, offering a modern solution that aligns with consumer demand for customization. This method involves printing images directly onto specialized films, making it a standout option for those in the textile printing industry. The DTF transfer application process is not only efficient but also caters to a wide range of fabrics, allowing for diverse design possibilities. As the trend towards eco-friendly DTF printing continues to rise, many businesses are embracing this sustainable approach to reach environmentally conscious consumers. These advancements in garment decoration have paved the way for creative expression while ensuring the longevity of high-quality prints.

Introduction to DTF Printing Techniques

DTF printing, or Direct-to-Film printing, is a standout method in the land of garment decoration, offering a unique approach to transfer designs onto various fabrics. At the core of DTF printing is the revolutionary technology that employs specialized printers to deposit vibrant, high-quality inks onto transfer films. This process not only allows for intricate designs and vibrant colors but also caters to the increasingly popular demand for customization in the fashion industry. By embracing DTF printing, businesses can harness unlimited creative possibilities that resonate well with diverse consumer tastes.

One of the appealing aspects of DTF printing techniques is their versatility. Unlike traditional methods, DTF can be applied on a wide variety of materials, including cotton, polyester, and even blends. This flexibility makes it a go-to solution for many smaller businesses looking to provide personalized apparel without the significant investments typical of other printing methods. The capability to produce their unique lines without limiting themselves to pre-printed fabrics enables creators to fully explore their artistic visions.

The Eco-Friendly Aspect of DTF Transfer Process

Eco-friendly DTF printing has emerged as a key player in the modern textile printing landscape, directly addressing the growing consumer concerns about the environmental impact of garment production. Unlike conventional printing techniques that often utilize harmful chemicals, the DTF transfer process incorporates sustainable practices such as water-based inks and recyclable transfer films. Manufacturers are continually innovating to reduce waste and utilize eco-conscious materials, thereby appealing to environmentally-aware consumers.

Moreover, eco-friendly DTF printing does not compromise quality. Practitioners can achieve the same level of detail and vibrancy using environmentally safe products. This not only aids in enhancing brand reputation but also contributes positively to an increasingly eco-conscious market, attracting a larger customer base that favors sustainable products. The melding of creativity with sustainability stands as a testament to the future of garment decoration, further solidifying DTF’s relevance in today’s fashion industry.

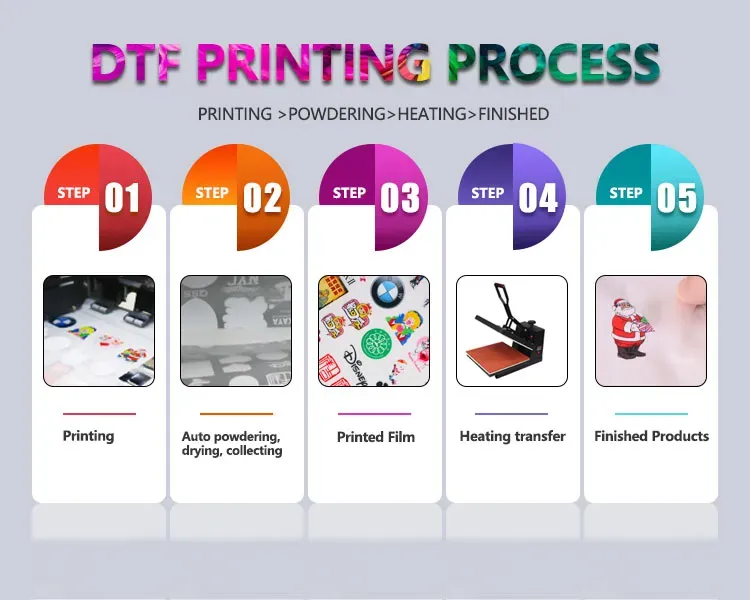

Step-By-Step Overview of DTF Transfer Application

The DTF transfer application process is a meticulous journey that begins with the design culmination and elegantly transitions into the garment application. Starting with design creation, artists utilize sophisticated software to craft their visions into reality. This initial phase sets the stage for printing on a PET film, which captures the essence of the artwork in a way that is ready for fabric application. Careful selection of design elements ensures that the final garment showcases stunning, high-quality imagery.

Following the creation phase, the actual printing onto the transfer film takes place using specially formulated inks that bond seamlessly with the fabrics during transfer. The heat application that follows is critical; it solidifies the bond between the adhesive powder and the fabric, making the design durable against washing and wear. This step-by-step overview of the DTF transfer application highlights how precision and careful planning result in enduring garment decorations.

Trends Shaping the Future of DTF Printing

Staying abreast of recent developments in the DTF printing market is essential for those looking to leverage its advantages. One prominent trend is the increasing demand for customization, with businesses of all sizes investing in DTF printing technologies to offer unique products. This customization wave is not limited to fashion; it extends to merchandise and promotional items, providing consumers with the opportunity to express individuality through personalized designs.

Another notable trend is the integration of technology to enhance printing efficiency and effectiveness. Newer DTF printers are equipped with advanced features that allow for higher resolution printing on diverse textiles, amplifying the appeal of the service. The movement toward automation and more efficient processes not only reduces labor costs but also shortens turnaround times, making DTF an attractive option for larger operations looking to scale.

Exploring Garment Decoration Techniques with DTF

The DTF transfer process is an innovative garment decoration technique loved for its flexibility and results. While traditional screen printing and heat transfer methods have their merits, DTF opens up new avenues, allowing for more detailed designs and vibrant color combinations. Its capability to print fine details with clarity enables businesses to deliver high-quality products with minimal imperfections, an essential quality in today’s discerning market.

Additionally, DTF printing’s simplistic approach not only advances the efficiency of the garment decoration process but also expands the toolkit for creators and entrepreneurs. The blending of various decoration techniques, such as embroidery and sublimation, with DTF printing allows for the creation of unique hybrid garments that stand out in the market while offering customers a variety of choices. This holistic approach underlines the versatility of DTF as a foundational method for garment decoration.

Conclusion: The Future of Textile Printing with DTF

As we look toward the future, it becomes clear that the DTF transfer process is shaping the landscape of textile printing. Its blend of quality, sustainability, and customization presents a compelling proposition for businesses aiming to thrive in a competitive marketplace. With technology advancements and a continued demand for eco-friendly practices, DTF printing is positioned not only to meet market demands but to lead in developing innovative garment decoration solutions.

In embracing DTF printing, businesses are not merely investing in a technique; they are adopting a philosophy that values creativity, sustainability, and customer satisfaction. Understanding the DTF transfer process is crucial for those seeking to maximize their creative potential and support sustainable practices in the textile industry. As the industry evolves, keeping an eye on DTF advancements will undoubtedly uncover new opportunities that await.

Frequently Asked Questions

What is the DTF transfer process and how does it work?

The DTF transfer process, or Direct-to-Film printing, involves several key steps to transfer designs onto garments. It begins with creating a design on graphic software, followed by printing that design onto a PET film using pigment-based inks. After applying a hot-melt adhesive powder to the printed film, heat is used to transfer the design onto the fabric, ensuring strong adhesion and high-quality print results.

How does DTF printing compare to other garment decoration techniques?

DTF printing stands out among garment decoration techniques due to its ability to produce vibrant, detailed designs with excellent durability. Unlike traditional methods such as screen printing, DTF allows for complex designs in lower quantities and is suitable for various fabrics. This process also minimizes waste and supports eco-friendly practices through the use of water-based inks and adhesives.

Can the DTF transfer application be used on all fabric types?

Yes, the DTF transfer application is versatile and can be used on a range of fabric types, including cotton, polyester, and blends. This adaptability makes Direct-to-Film printing a popular choice for various apparel items, ensuring high-quality results regardless of the material.

What advantages does eco-friendly DTF printing offer?

Eco-friendly DTF printing provides numerous benefits, including the use of environmentally safe inks and adhesives that reduce harm to the planet. This sustainable approach not only appeals to environmentally conscious consumers but also aligns with growing market trends focusing on sustainability in fashion, making DTF a forward-thinking option in garment decoration.

How do advancements in technology impact the DTF transfer process?

Advancements in technology enhance the DTF transfer process by improving printer efficiency, reliability, and print quality. Modern DTF printers are equipped to produce high-resolution designs quickly and on various fabrics, addressing previous durability concerns and making this method more accessible for both small businesses and large-scale operations.

What precautions should be taken during the peeling phase of the DTF transfer process?

During the peeling phase of the DTF transfer process, it is crucial to allow the film to cool slightly after heat pressing before carefully peeling it away from the fabric. Peeling too soon can result in smeared designs or poor adhesion. Following this step ensures the transfer remains intact and vibrant, ready for wear.

| Key Steps | Description |

|---|---|

| 1. Design Creation | Involves creating designs using graphic design software, ensuring file formats support transparency for better integration. |

| 2. Printing on Film | Printing the design onto PET film with specialized DTF printers using pigment-based inks. |

| 3. Adhesive Application | Dusting the printed film with hot-melt adhesive powder and curing it to activate the adhesive. |

| 4. Transfer to Garment | Using a heat press to apply high temperatures and pressure on the film to bond the design with the fabric. |

| 5. Peeling and Finishing | Carefully peeling the film after cooling to ensure design integrity, followed by an optional final heat press. |

Summary

The DTF Transfer Process has emerged as a transformative methodology in textile printing, encompassing a series of well-defined steps ranging from design creation to the final application on garments. This process not only promises vibrant and durable prints but also reflects a growing trend towards environmental sustainability within the industry. As consumer demands shift towards customization and eco-friendly solutions, the DTF transfer process positions itself as an essential technique for modern garment decoration. By integrating advanced technology with creative possibilities, it continues to evolve, offering both entrepreneurs and fashion enthusiasts exciting avenues for expression and sustainable practices.