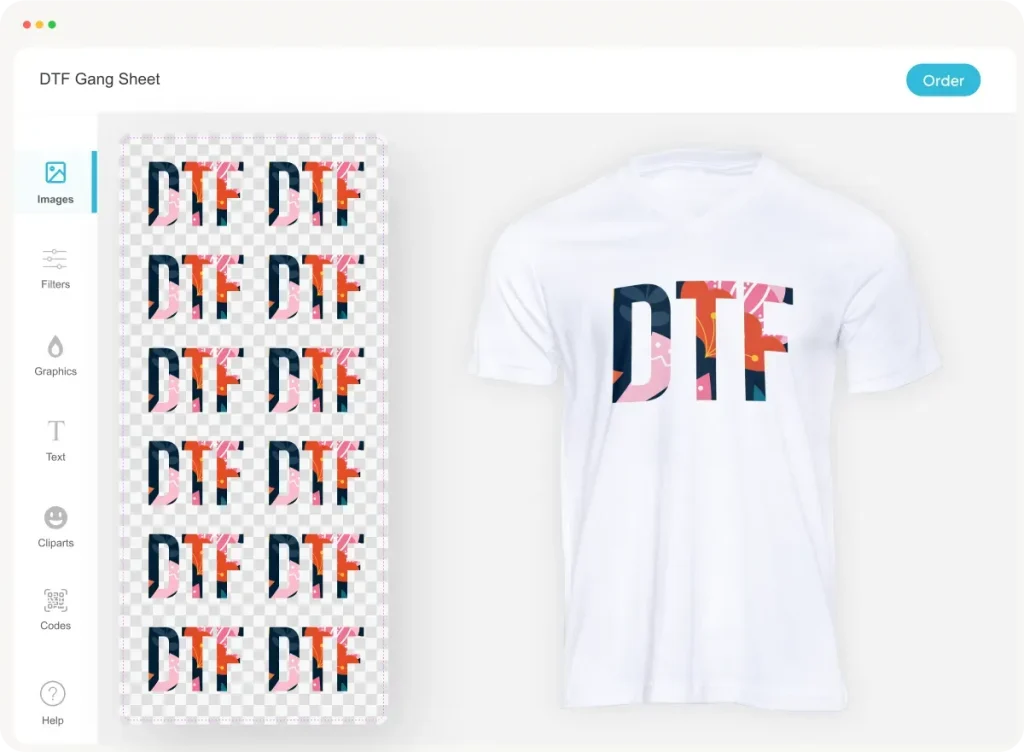

The **DTF gangsheet builder** is revolutionizing how designers approach fabric printing by maximizing efficiency and reducing waste. With the ability to arrange multiple designs on a single sheet, this tool enhances the DTF printing process, ensuring vibrant outputs and high detail. For those involved in garment production, mastering the art of design creation through a gangsheet arrangement can significantly elevate the quality of the final product. This innovative approach not only streamlines the transfer process but also establishes rigorous quality control measures that guarantee exceptional results. As the demand for custom printing increases, leveraging a DTF gangsheet builder can set your creations apart in a competitive market.

In the realm of fabric printing, tools known as **Direct-to-Film gangsheet generators** are emerging as essential for efficient design production. By facilitating the arrangement of multiple patterns or graphics on a single transfer sheet, these generators optimize resources and yield stunning visuals. The process, often referred to as DTF application, includes meticulous steps from design creation to quality assurance, ensuring that each transfer retains its vibrancy and clarity. This method not only caters to individualized projects but also supports large-scale production, making it an invaluable asset for businesses in the printing industry. For professionals seeking to enhance their workflow and outcomes, utilizing gangsheet solutions is a game changer.

Understanding DTF Printing Technology

Direct-to-Film (DTF) printing represents a significant advancement in the fabric printing industry. This method not only offers vibrant coloration but also preserves the fine details of designs that traditional printing techniques often struggle to achieve. With DTF printing, the application process is streamlined, allowing for quick reproduction of complex design elements on various fabrics. The innovative transfer process ensures that colors display exceptionally well, even on dark or textured materials, making DTF a versatile option for designers.

Utilizing a DTF gangsheet builder particularly enhances the DTF printing experience. This tool aids in consolidating multiple designs onto a single sheet, ultimately optimizing ink usage and minimizing production costs. By effectively grouping designs, the gangsheet builder simplifies both the printing and transfer processes, ensuring that you can efficiently create high-quality outputs without excessive waste or time loss. This efficiency is becoming increasingly vital in today’s competitive market.

Mastering Design Creation for DTF Printing

Creating visually appealing designs is pivotal in the context of DTF printing. To initiate this process, graphic design software plays a fundamental role; applications like Adobe Illustrator and CorelDRAW are preferred for their extensive features. When embarking on design creation, it is crucial to ensure that images maintain a resolution of at least 300 dpi for quality assurance. The choice of file formats is equally important; using PNG files, which support transparency, will facilitate smoother transfers and clearer designs.

Effective design creation also involves utilizing layers strategically. By separating different elements of a design onto distinct layers, adjustments become significantly easier throughout the workflow. This approach not only allows for better organization but also enhances the final product’s quality, ensuring each aspect of the design can shine through independently. Mastering these design creation techniques is invaluable for those looking to make a mark in the fabric printing industry.

Efficient Gangsheet Arrangement Techniques

Once your designs are finalized, the next critical step is the gangsheet arrangement. This process is vital as it maximizes the use of available printing space and minimizes material waste. The DTF gangsheet builder offers an intuitive interface for aligning and positioning various designs. By arranging multiple graphics effectively, you can ensure that your printing process is streamlined, ultimately leading to better productivity and reduced costs.

Attention to detail during the arrangement stage cannot be emphasized enough. Proper spacing and orientation between designs are essential to prevent issues during the transfer process. Overlapping designs can complicate the application and affect the overall quality of the print. By conducting a preliminary preview of your gangsheet layout, you can identify potential issues before proceeding, ensuring that each print passes the quality control checks seamlessly.

Setting Up for Successful DTF Printing

Preparing your DTF printer is a vital step before diving into the actual printing of your designs. Each printer model may have specific configurations you’ll need to account for, including ink types and film compatibility. Start by consulting your printer manual to ensure optimal settings are in place, which will safeguard against misprints and enhance your printing quality. Additionally, having the correct film loaded is essential for achieving the best results.

Part of the setup process also includes calibrating the ink density to match the material you are working with. Adjusting the color profiles according to the fabrics can substantially improve the final outcome, leading to prints that are vibrant and precise. Especially when working with diverse fabric types, fine-tuning these settings helps you achieve a range of effects, from bold colors on lighter fabrics to deep, rich hues on darker materials.

The Critical Transfer Process in DTF Printing

After the printing stage, the transfer process marks a critical step in DTF printing. It is during this phase that printed designs are transferred onto the desired fabric. Applying the powder adhesive while the ink remains wet is a crucial component of this process, as it ensures that the ink binds effectively to the substrate. Failure to carry out this step properly can compromise print quality, leading to peeling or fading of the transferred design.

Once the adhesive is applied, the curing stage follows. Utilizing a heat press or curing oven is essential for allowing the adhesive and ink to bond completely to the fabric. The temperature and timing here are pivotal; each fabric type may require different settings to achieve optimal results. Consistently adhering to manufacturer guidelines during this phase will ensure durability and clarity in your designs, leading to a higher level of customer satisfaction.

Implementing Quality Control for Superior Output

After completing the printing and transfer processes, conducting stringent quality control is essential. This step involves closely inspecting the finished products for clarity in prints, accuracy in colors, and proper adhesion to the fabric. Each of these factors plays a crucial role in the overall quality of your prints and impacts customer perceptions significantly. Ensuring that all output meets high standards of quality helps solidify your reputation in the fabric printing market.

Quality control is not just a final step but an ongoing process that should be integrated into your printing operations. Collecting feedback from customers and evaluating returned products can provide insights into potential areas for improvement. By consistently refining your techniques and maintaining high standards, you can foster long-lasting customer relationships and enhance your business’s credibility in a competitive landscape.

Frequently Asked Questions

What is a DTF gangsheet builder and how does it work?

A DTF gangsheet builder is a tool used in Direct-to-Film (DTF) printing that allows users to arrange multiple designs on a single sheet, optimizing material usage and minimizing waste. It helps streamline the design creation process and enhances the efficiency of transferring prints onto fabrics.

How can I create designs for my DTF gangsheet builder?

To create designs for your DTF gangsheet builder, use graphic design software like Adobe Illustrator or CorelDRAW. Ensure your designs are high resolution (300 dpi or more) and saved in compatible formats like PNG for transparency. Organizing designs into layers will simplify adjustments and enhance the overall quality.

What are the best practices for gangsheet arrangement in DTF printing?

When arranging your designs in a DTF gangsheet builder, prioritize maximizing print space by adjusting the position and spacing of each graphic. Avoid overlapping designs to prevent complications during the transfer process. Always preview the layout before finalizing to ensure optimal placement.

What printing setup is required for using a DTF gangsheet builder?

For optimal results with a DTF gangsheet builder, configure your DTF printer settings based on the specific inks and films being used. It’s essential to load the correct film and refer to the printer’s manual for recommended settings, as each model may have unique requirements.

How do I perform the transfer process after printing with a DTF gangsheet?

After printing your gangsheet, apply a powder adhesive to the printed side while the ink is wet. This adhesive is critical for proper bonding with the fabric. Next, cure the design using a heat press or curing oven, following the recommended temperature and time settings to ensure quality and durability.

What steps should I take for quality control in DTF printing?

Conduct quality control by inspecting the finished products for clarity of prints, color accuracy, and proper adhesion to the fabric. This step is vital to confirm the quality of your DTF prints before distribution, helping to ensure customer satisfaction and reduce returns.

| Key Point | Details |

|---|---|

| Introduction to DTF Gangsheet Builder | A vital tool in DTF printing that allows for multiple designs on a single sheet, improving efficiency and reducing waste. |

| Understanding DTF Printing | DTF printing provides vibrant colors and high detail, making it popular in fabric printing. |

| Design Creation | Use graphic design software like Adobe Illustrator or CorelDRAW to create high-resolution designs. |

| Gangsheet Arrangement | Arrange designs on the sheet with attention to spacing to avoid overlaps. |

| Printing Setup | Configure printer settings according to ink and film types used, following printer guidelines. |

| Transfer Process | Apply powder adhesive while ink is wet, and cure using a heat press for proper adhesion. |

| Quality Control | Inspect prints for clarity, color accuracy, and adhesion before delivering to customers. |

| Resources for Learning | Utilize YouTube, Avery, and Printful for tutorials and community advice on DTF printing. |

Summary

The DTF gangsheet builder is an essential tool for anyone looking to create stunning designs in the fabric printing industry. By mastering each step, from design creation to quality control, users can enhance their production efficiency and achieve high-quality results that distinguish their products in the market. Staying informed through tutorials and community interactions will further empower users to refine their skills and keep up with the latest trends in DTF printing.