The DTF printing process, or Direct-to-Film printing, has taken the custom apparel industry by storm, combining quality and versatility in a seamless manner. This revolutionary method allows for striking, detailed designs to be printed directly onto special transfer films, making it ideal for a variety of fabric types. If you’re diving into DTF printing for beginners, this guide will demystify the necessary steps, materials, and techniques to get you started. From understanding the benefits of DTF printing to properly preparing your workspace, we’ll cover everything you need to know. Whether you are looking to create unique fashion pieces or promotional items, mastering DTF printing can elevate your creative projects to new heights.

Direct-to-Film (DTF) printing represents a significant evolution in the realm of fabric printing techniques. Often preferred for its ability to produce vibrant colors and detailed imagery, this alternative printing method caters to both established businesses and newcomers. By utilizing water-based inks applied to specialized transfer films, DTF enables transfers to a wide range of textiles effortlessly. Many enthusiasts and entrepreneurs consider exploring this technique due to its ease of use and the quality of finished products. As we delve deeper into this Direct-to-Film printing guide, you’ll discover how to effectively harness this innovative method for your custom printing needs.

What is DTF Printing?

Direct-to-Film (DTF) printing is an innovative printing method that has transformed the custom apparel industry. This technique involves printing designs onto a specialized transfer film using water-based inks, which are then heat-transferred onto fabrics. Unlike traditional printing methods, DTF printing allows designers to create intricate and colorful designs with impressive detail. The flexibility of DTF makes it suitable for a variety of textiles, including cotton, polyester, and blends, making it an appealing choice for businesses looking to diversify their product offerings.

One of the standout characteristics of DTF printing is its ability to achieve vibrant colors and sharp details. The process utilizes a unique combination of adhesive powders and heat, which allows the inks to bond effectively to the fabric. This results in high-quality prints that are durable and can withstand regular wear. As more entrepreneurs recognize the advantages of DTF, this technique is quickly becoming a go-to method for those wanting to create custom apparel with remarkable visual appeal.

Benefits of DTF Printing for Custom Apparel

DTF printing offers a range of benefits that make it a favorable choice for custom apparel decoration. Firstly, its versatility allows businesses to print on a wide variety of fabrics, from cotton to synthetic blends. This adaptability means that DTF printing can cater to a diverse customer base, accommodating different styles and fabric preferences. As a result, entrepreneurs can expand their businesses by offering a broader selection of products.

Additionally, one of the most significant advantages of DTF printing is cost-effectiveness. Compared to traditional printing techniques, DTF has lower setup costs and requires less time to produce high-quality results, making it an ideal option for small businesses and startups. Moreover, the vibrant colors and intricate details achieved through DTF printing help attract customers, ultimately boosting sales and brand recognition.

Essential Materials Needed for DTF Printing

To successfully initiate the DTF printing process, certain materials are essential for achieving high-quality prints. The foundation of DTF printing lies in the specialized DTF printer, which is often a modified inkjet printer specially designed for using water-based inks. Along with the printer, you will require DTF inks that are compatible with your specific printer model, ensuring optimal results.

Another critical component is the transfer film, which is coated to accept the printed ink. This film plays a vital role in ensuring that the design transfers smoothly onto the fabric. Additionally, a hot melt adhesive powder is necessary to bond the ink to the fabric during the heat transfer process. Finally, having a reliable heat press is crucial for applying the right amount of heat and pressure to ensure the designs are effectively fused to the fabric.

Step-by-Step Guide to the DTF Printing Process

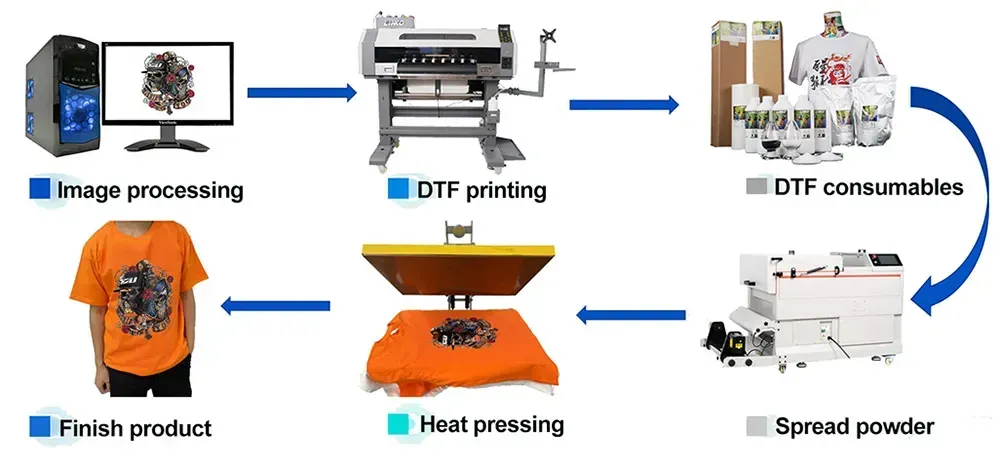

Embarking on the DTF printing journey requires a precise understanding of the entire process. The first step involves designing your artwork using graphic design software, such as Adobe Illustrator. It’s crucial to ensure that your designs are reversed before printing since the transfer film will flip the image. Once your design is ready, print it onto the DTF transfer film using your specially equipped printer, adjusting the settings for maximum quality.

After printing, the next step is to apply the adhesive powder to the still-wet ink. This step is critical, as the adhesive must bond with the ink before it dries. Once the adhesive is applied, the film should be heated to cure the adhesive, ensuring a durable transfer. Finally, position the cured transfer onto the fabric and use a heat press to apply the necessary heat and pressure, resulting in a seamless and vibrantly printed design on your chosen material.

Tips for Achieving Successful DTF Prints

To perfect your DTF printing process, consider implementing several helpful tips. Firstly, always conduct test prints on sample fabrics before committing to final garments. This step allows you to evaluate color accuracy and adhesion quality, ensuring your final products meet your standards. Additionally, maintain your printer and heat press equipment regularly to avoid common issues that can compromise print quality.

Experimenting with different fabric types can also yield varied results and help you discover the best combinations for your designs. Keep a log of your test results to determine which fabrics, inks, and settings produce the most successful prints. This practice not only refines your technique but also enhances your overall understanding of the DTF printing process.

The Future of DTF Printing and Recent Advances

As technology continues to evolve, the DTF printing landscape is rapidly advancing, with recent innovations enhancing both the quality and accessibility of this printing method. Improved ink formulations have emerged, providing greater flexibility and durability of prints, which contributes to the longevity of custom apparel. Moreover, as more manufacturers develop affordable DTF printers, the entry barriers for aspiring entrepreneurs are significantly lowered.

These advances not only open the door for small businesses to adopt DTF printing but also broaden the creative possibilities for custom apparel creation. As the market for personalized clothing continues to grow, staying informed about technological developments in DTF printing will be invaluable for those looking to remain competitive and innovative in the industry.

Frequently Asked Questions

What materials are needed for the DTF printing process?

To start with DTF printing, you’ll need a DTF printer, compatible water-based DTF inks, specialized DTF transfer film, hot melt adhesive powder, and a heat press. These materials are essential to successfully execute the DTF printing process.

How does the DTF printing process work for beginners?

For beginners, the DTF printing process involves creating a design, printing it onto transfer film, applying adhesive powder, curing it, and then transferring the design onto fabric with heat. Following these steps ensures vibrant and high-quality prints.

What are the benefits of DTF printing compared to other methods?

DTF printing offers several benefits, including the ability to print on various fabrics, vibrant colors, intricate details, an easier setup for beginners, and affordability. These advantages contribute to its popularity among custom apparel printers.

Can I use any fabric with the DTF printing process?

Yes, the DTF printing process is versatile and can be used on a variety of fabrics, including cotton, polyester, and fabric blends. This makes it suitable for a range of apparel items.

What is the key to achieving successful results in the DTF printing process?

To achieve success in DTF printing, it’s crucial to prepare your design in reverse, maintain your equipment, use high-quality materials, and test prints on sample fabrics before finalizing your designs.

What should I know about DTF printing for beginners?

Beginners should understand the basics of the DTF printing process, including the required materials and equipment, key steps for printing and transferring designs, and the numerous benefits that make DTF printing a favorable choice in custom apparel creation.

| Aspect | Details |

|---|---|

| Definition | DTF printing stands for Direct-to-Film printing, a method where designs are printed onto transfer film using water-based inks. |

| Process | 1. Design Creation 2. Printing the Design 3. Applying Adhesive 4. Curing the Transfer 5. Transferring to Fabric 6. Peeling the Film |

| Materials Needed | – DTF Printer – DTF Inks – Transfer Film – Adhesive Powder – Heat Press |

| Benefits | – Versatile for different fabric types – Vibrant colors and fine details – Easy to set up for beginners – Cost-effective compared to other methods |

| Recent Advances | Improved ink formulations & affordable printers are expanding DTF printing use among small businesses and creators, enhancing creative possibilities. |

Summary

The DTF printing process is reshaping the landscape of custom fabric printing, blending innovation and simplicity. This modern approach provides users with the ability to create intricate and vibrant designs on various fabrics with ease, making it a suitable choice for beginners and established businesses alike. By utilizing this step-by-step guide, you’ll not only understand the essentials of the DTF printing process but also access the creative potential it offers in personal or commercial projects. Exploring your options in the world of DTF printing could open up a range of possibilities for unique and customized apparel.