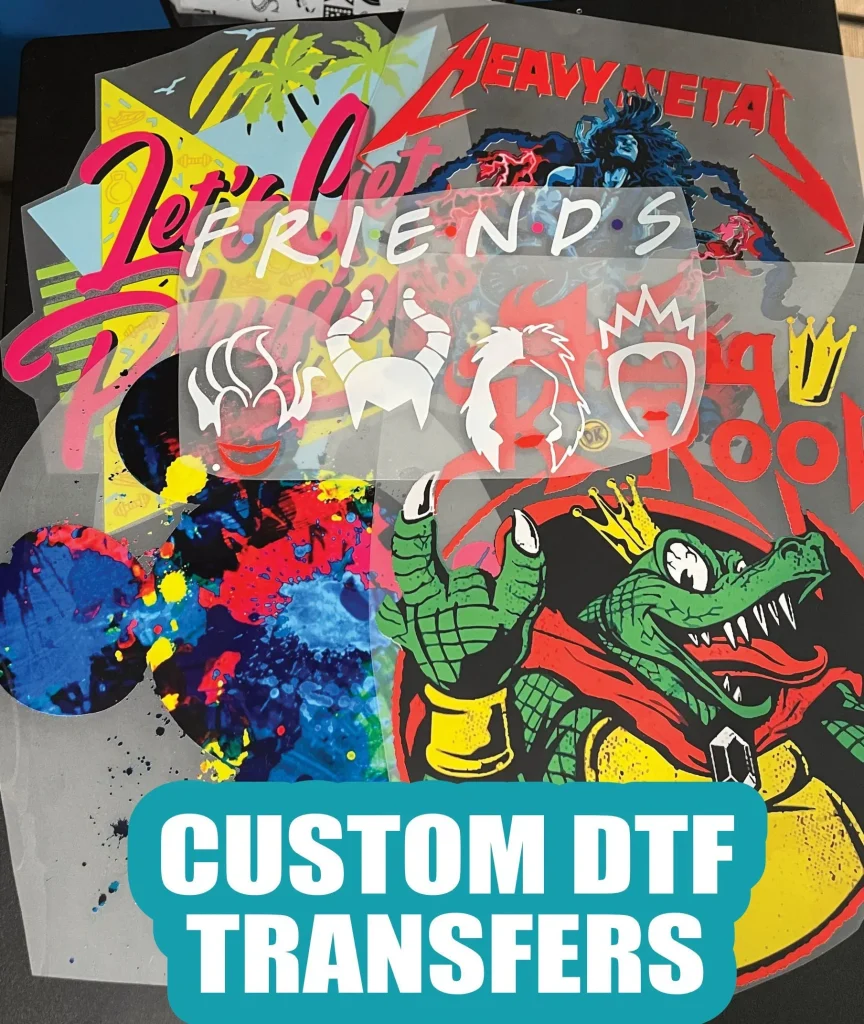

DTF transfers, or Direct-to-Film printing, are revolutionizing the world of custom apparel with their innovative printing techniques. This advanced process allows for the creation of vibrant, intricate designs that adhere seamlessly to various surfaces, making it a favorite among businesses and creators alike. With DTF printing benefits such as exceptional durability and color reproduction, it stands out from traditional printing methods like screen printing. Whether you’re a small business owner or a creative artist, understanding the fundamentals of DTF transfers can significantly improve your custom merchandise offerings. As this print technology continues to evolve, embracing it can lead to new opportunities and heightened efficiency in your projects.

Direct-to-Film printing (DTF) is an exciting development in the custom printing industry that harnesses new technologies to produce stunning results. Often referred to as film transfer printing, this method employs specially coated films to achieve detailed graphics and vibrant colors on a variety of materials. The versatility of this print technology means that it can cater to a broad range of applications, from promotional products to high-quality apparel. By understanding the advantages of this technique, creatives can unlock a wealth of possibilities for their custom projects. Overall, the innovation surrounding DTF transfers presents an excellent opportunity for businesses to enhance their product offerings and stand out in a competitive marketplace.

Understanding DTF Transfers: The Future of Custom Printing

DTF transfers, or Direct-to-Film printing, have become a game-changer in the custom printing industry. This innovative technique allows for the creation of high-quality designs that can be applied to a variety of materials. Unlike traditional methods such as screen printing, which can be labor-intensive and costly, DTF provides a streamlined process that is both efficient and versatile. By leveraging advanced print technology, businesses can now produce intricate designs with vibrant colors that truly stand out in the market.

The essence of DTF’s appeal lies in its adaptability; whether you are designing custom apparel or promotional items, DTF transfers can fulfill diverse needs. This flexibility not only opens up new creative avenues for designers but also meets the various requirements of brands looking to enhance their merchandise. Understanding the capabilities of DTF printing can equip you with the knowledge to elevate your branding efforts and capture the consumer’s attention.

Key Benefits of DTF Printing for Custom Apparel

When it comes to custom apparel, DTF printing offers several notable benefits that can significantly enhance your product offering. One of the primary advantages is the ability to achieve high-resolution graphics that maintain their quality even after multiple washes. This durability means that the custom apparel you create will not only look fantastic on the first wear but will sustain its vibrancy over time, ensuring customer satisfaction.

Additionally, DTF printing is cost-effective for small batch production, making it ideal for businesses looking to experiment with designs without incurring hefty setup costs. This affordability allows creators to test new concepts and expand their product lines without committing to large quantities, thereby minimizing waste and maximizing profitability. As custom apparel continues to trend, understanding the economic advantages of DTF printing can provide craftsmen with a competitive edge.

Technological Innovations in DTF Transfers

The world of DTF printing is constantly evolving, shaped by advancements in technology and market demand. Recent innovations have introduced new equipment and techniques that streamline the DTF process. For instance, the emergence of specialized DTF printers has made it easier for both novice and experienced users to achieve high-quality prints with minimal effort. As a result, businesses can now operate more efficiently and focus on scaling their production capabilities.

Moreover, developments such as gang sheets have revolutionized the way designs are processed. By permitting multiple designs to be printed on a single film, gang sheets maximize the use of materials and reduce overall costs. This eco-friendly approach not only caters to budget-conscious businesses but also addresses growing environmental concerns, solidifying DTF printing’s place in the sustainable market.

Starting Your Journey with DTF Transfers

Embarking on your DTF printing journey can seem daunting, but with the right approach, it can be a rewarding venture. The first step is investing in quality equipment, including a reliable DTF printer and an efficient heat press. Quality tools are essential to ensure that your printing process runs smoothly and that your final products meet the high standards expected by customers.

Next, familiarize yourself with graphic design software to craft stunning designs that will captivate your audience. Mastery of software like Adobe Illustrator or CorelDRAW will significantly enhance your design capabilities. Lastly, experimentation is key; start with small test prints to perfect your settings and ensure that you achieve the desired results. This phase of learning will empower you to create exceptional custom prints.

Comparing DTF Transfers with Traditional Printing Methods

When evaluating various printing techniques, it’s evident that DTF transfers offer distinct advantages over traditional options like screen printing or sublimation. For instance, while screen printing is efficient for high volumes, it can become cumbersome with complex designs due to the setup involved. DTF printing eliminates this challenge, providing flexibility to produce intricate and colorful graphics quickly without the need for extensive preliminary work.

Moreover, unlike sublimation, which is limited to certain types of fabrics, DTF transfers are versatile enough to print on a wide array of materials. This versatility allows businesses to expand their offerings to include various products, such as custom bags or home décor items, showcasing the diverse potential of DTF printing as a tool for creativity and business growth.

Why DTF Printing is a Smart Investment for Your Business

Investing in DTF printing technology stands as a wise decision for businesses looking to enhance their product range. The demand for customization is on the rise, and DTF transfers meet this demand exceptionally well by providing high-quality prints quickly and affordably. As more customers seek unique and personalized items, DTF printing can help businesses capture this lucrative market segment.

Furthermore, with DTF printing’s ability to produce designs with intricate details and vibrant colors, businesses can achieve higher customer satisfaction and loyalty. As the market continues to shift towards personalized merchandise, stay ahead by adopting this innovative print technology, ensuring your offerings stand out among competitors. Investing in DTF could be the catalyst that transforms your creative ideas into profitable ventures.

Frequently Asked Questions

What are the main benefits of using DTF transfers for custom apparel?

DTF transfers, or Direct-to-Film printing, offer numerous advantages for custom apparel, including vibrant colors, intricate details, and exceptional durability. This print technology adheres well to various surfaces, makes small batch production cost-effective, and provides wash resistance, ensuring your custom designs look great wear after wear.

How does DTF printing compare to traditional printing techniques?

Unlike traditional methods such as screen printing that require extensive setup and are better suited for large batches, DTF printing excels in producing high-quality prints on a variety of materials with minimal upfront costs. It also allows for more intricate designs and offers greater versatility in applications.

Is DTF printing suitable for both small and large production runs?

Yes, DTF printing is exceptionally suited for both small and large production runs. It eliminates the high setup costs associated with traditional methods, making it ideal for custom merchandise or limited runs while still providing efficiency for larger orders.

What materials can DTF transfers be applied to?

DTF transfers can be applied to a wide range of materials, including cotton, polyester, blends, and even non-fabric surfaces like plastics. This versatility allows businesses to create custom products across various applications, from apparel to promotional items.

Do DTF transfers have good wash resistance compared to other printing methods?

Yes, DTF transfers are known for their strong adhesion properties and excellent wash resistance when applied correctly. This makes them particularly advantageous for custom apparel that undergoes regular washing, maintaining vibrant designs over time.

What should I consider when starting with DTF transfers?

When starting with DTF transfers, consider investing in quality equipment like a reliable DTF printer and heat press, learning graphic design software for your custom creations, and sourcing high-quality transfer film and adhesive to ensure optimal print results.

| Aspect | Description |

|---|---|

| Definition | DTF transfers, or Direct-to-Film printing, is a method of printing designs onto transfer film, then applying them to various substrates. |

| Process | 1. Create a design, 2. Print on film, 3. Apply adhesive powder, 4. Heat transfer to surface. |

| Advantages | Versatile surfaces, vibrant colors, durability, cost-effective for small batches. |

| Innovations | New platforms and products reduce lead times and maximize efficiency. |

| Getting Started | Invest in equipment, learn design software, source quality materials, and experiment. |

| Comparison | DTF offers flexibility and versatility over screen printing and sublimation. |

Summary

DTF transfers represent a revolutionary technique in the custom printing domain, merging creativity with advanced technology. With their ability to produce high-quality, durable prints on various surfaces, DTF transfers cater to a broad range of applications, making them an ideal choice for both crafters and businesses. Emphasizing vibrant color reproduction and wash resistance, this innovative method outshines traditional printing techniques, ensuring an exceptional final product. As the DTF transfers market continues to grow, understanding its nuances can significantly enhance one’s ability to deliver exceptional results, catering effectively to diverse customer needs.