Care and Washability for DTF Transfers is essential for anyone who loves custom apparel. DTF transfers care guides you on keeping colors vibrant, the print soft to the touch, and the bond lasting through wear across many garments. DTF transfer durability depends on proper curing and a thoughtful post-application routine for best adhesion across fabrics. This guide also emphasizes washing practices that protect edges and keep color fast over many cycles, including turning garments inside out and choosing gentle cycles. If you’re curious about long-term performance, you’ll want to follow these steps to maximize life and enjoy vibrant prints for seasons.

Viewed from a different angle, this topic resembles a guide to the lasting appeal of heat-applied graphics on textiles and the routine care that preserves those designs. LSI-friendly terms include print longevity, post-press curing, garment washing guidelines, and fabric compatibility across cottons, blends, and synthetics. By aligning temperature, pressure, and care routines, creators and wearers can extend the life of their custom apparel while maintaining color fidelity.

Frequently Asked Questions

What are the essential DTF transfers care steps to maximize durability?

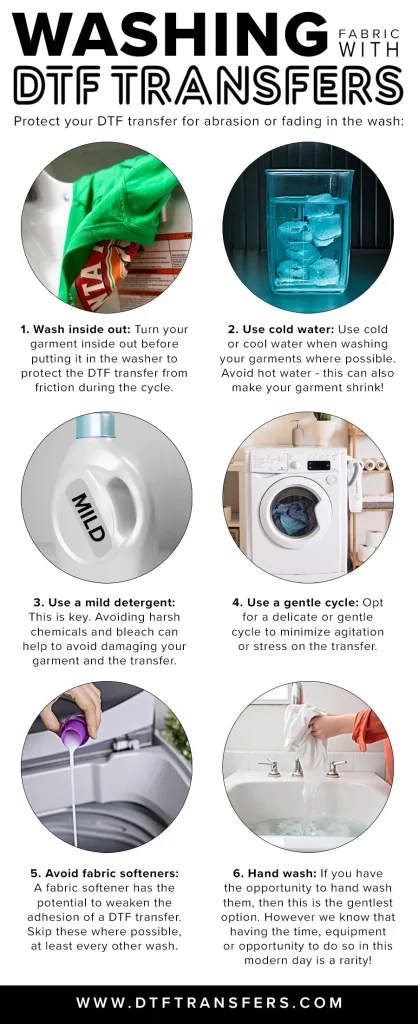

Key DTF transfers care steps include ensuring full cure before washing, then washing inside-out in cold to warm water with a mild, enzyme-free detergent. Avoid bleach and fabric softeners; use a gentle cycle and air dry or tumble on low heat to boost DTF transfers care and durability.

What are the recommended wash instructions for DTF transfers to preserve color and adhesion?

Follow wash instructions for DTF transfers: turn the garment inside-out, wash in cold water with a mild detergent, avoid bleach and fabric softeners, and choose a gentle cycle. Skip dryer sheets and either air dry or use a low-heat dryer setting to protect the print.

How long do DTF transfers last under proper care, and what factors influence longevity?

How long do DTF transfers last? With proper care and curing, many designs withstand dozens of washes, but longevity varies by fabric, design complexity, and color saturation. Following wash instructions for DTF transfers and maintaining a gentle routine will maximize life.

What heat settings for DTF transfers yield reliable adhesion without damaging the print?

Heat settings for DTF transfers should follow manufacturer guidance and apply even pressure. Excessive heat or time can soften or warp the adhesive and shorten longevity, so start with recommended temps and adjust based on fabric type.

Why is curing time important for DTF transfers, and how does it affect long-term durability?

DTF transfer durability relies on a proper cure. Fully curing the print before washing strengthens the bond and reduces lift; allow at least 24 hours to cure and then use cold/gentle washing to preserve durability.

What signs indicate wear and how should you adjust wash instructions for DTF transfers to extend life?

Watch for signs like cracking, peeling, or edge fray, which suggest care or cure issues. Reassess cure time, heat settings, and wash routine, and always follow wash instructions for DTF transfers to extend the design’s life.

| Section | Key Points | Practical Tips |

|---|---|---|

| What Are DTF Transfers & Longevity | DTF transfers are printed onto a special film and cured with adhesive before applying to fabric with a heat press. Longevity depends on adhesive chemistry, the heat/pressure used during application, and how the garment is cared for afterward. A durable bond is possible, but edge wear and color changes hinge on these variables. | Ensure proper cure time; follow recommended cure and application parameters; allow full curing before washing to maximize durability. |

| Major Factors Affecting Longevity | Fabric compatibility, application parameters, post-press curing, washing/drying methods, detergents/additives, and general garment care all influence how long DTF transfers last. | – For best results, use fabrics that tolerate the transfer (natural fibers like cotton often perform best). – Calibrate cure time, temperature, and pressure during heat pressing. – Allow full post-press curing before washing. – Wash gently; avoid hot cycles, harsh detergents, and aggressive agitation. – Use mild detergents and avoid bleach. – Be mindful of friction, sun exposure, and abrasion on the garment. |

| Care and Washing Guidelines for Maximum Longevity | Follow specific guidelines to preserve longevity: wash inside-out; use cold to warm water; choose a mild, enzyme-free detergent; run a gentle cycle; avoid fabric softeners and dryer sheets; air dry or use low heat; iron on reverse with a cloth barrier; consider pre-washing new garments before applying transfers. | – Wash inside-out to reduce surface friction. – Use cold to warm water; hot water accelerates wear. – Use mild, enzyme-free detergent; avoid bleach. – Select a gentle cycle and minimal agitation. – Skip fabric softeners and dryer sheets. – Air dry preferred; if using a dryer, choose low heat. – Iron on reverse with a cloth barrier; do not iron directly on the print. – Pre-wash new garments if possible. |

| Practical Scenarios: Fabric Types and Care Nuances | Different fabrics react differently to DTF transfers: 100% cotton tees are generally very compatible; cotton-poly blends can be forgiving but need careful heat settings; performance fabrics (polyester/blends) may require adjustments; dark colors often show edge wear more readily than light colors. | – For 100% cotton, follow guidelines and cure properly for minimal edge wear. – For blends, monitor heat and time to avoid scorching or ghosting. – For performance fabrics, test adhesion and flexibility; adjust heat/press time as needed. – Dark colors: use gentle care to preserve color depth; regular, careful washing helps maintain contrast. |

| Curing and First-Wash Considerations | Allow full curing time after pressing (ideally 24 hours) to let the adhesive set. First washes should be treated with extra care to avoid premature edge wear; monitor for signs of wear and adjust future parameters accordingly. | – Let garments cure fully; 24 hours if possible. – Be extra cautious with first few washes. – If you notice cracking or edge wear, reassess cure and press parameters for future projects. |

| Common Mistakes and How to Avoid Them | Rushing from pressing to washing, washing at high temperatures, overloading the machine, using harsh detergents or bleach, and ignoring fabric type can all reduce longevity. | – Do not skip cure time. – Use cold or gentle warm cycles. – Avoid overloading. – Use mild detergents; skip bleach. – Tailor care to the fabric used for the transfer. |

| Durability Expectations & Real-Life Longevity | Durability varies by design complexity, color saturation, and daily wear. Professionally cured transfers typically withstand dozens of washes when cared for properly, but aggressive use or chlorine cleaners can shorten life. | – Expect higher longevity with simpler designs on cotton and proper cure. – Do not assume all fabrics perform the same; adjust care accordingly. – Avoid chlorine-based cleaners if possible to preserve colors and adhesive. |