Florida DTF 101 offers a practical, beginner-friendly roadmap for anyone in the Sunshine State who is curious about custom apparel, outlining what this approach is, why it’s becoming popular, and how a novice can begin confidently. The guide breaks down the essentials, from understanding the core benefits to identifying realistic timelines and choosing entry points that suit Florida’s market pace. It also helps you map a practical path—from equipment considerations to workspace setup and initial orders—so you can avoid common missteps while you test your ideas. If you’re weighing whether to launch a side hustle or a full shop, this resource offers a clear framework for budgeting, sourcing, and building a repeatable workflow. By focusing on fundamentals and climate-aware operations, you’ll exit with a concrete plan you can start implementing this quarter.

In Florida, this emerging method is often described as direct-to-film printing—a film-based, heat-transfer technique that yields vibrant graphics on a wide range of fabrics. From another angle, you can view it as a film transfer workflow that begins with design and ends with a pressed garment, with adhesive powder playing a key role in durability. Understanding these terms helps designers compare equipment, ink compatibility, and substrate options, while keeping the focus on practical outcomes like color fidelity and wash fastness. As you learn, you’ll connect with broader topics such as platen size, heat press calibration, and vendor choices, all of which support a flexible, on-demand apparel business in Florida.

DTF Printing in Florida: What It Is and Why It Works Locally

DTF printing is a flexible heat-transfer method that prints designs on a special film, adds adhesive powder, cures it, and then transfers the image to fabric with a heat press. For Florida designers, DTF printing Florida unlocks fast customization for beachwear, event tees, and team gear. The process yields vibrant colors, soft hand feel, and broad fabric compatibility, making it a practical choice for small shops and side hustles in Florida’s markets. Understanding the DTF transfer process helps you vet substrates like cotton, blends, and even performance fabrics that Floridians demand in warm climates.

Getting started locally means aligning options with Florida-specific realities: humidity, heat, and supply access. When you explore DTF inks and media, you’ll look for textile-grade inks that resist wash and sun exposure common in sunny climates. The right film and adhesive powder deliver durable transfers, while a solid DTF printer setup—with stable power, a clean drying zone, and reliable RIP software—minimizes headaches. This foundation supports consistent results from St. Augustine to Naples and beyond.

Florida DTF 101: A Beginner’s Roadmap for Florida Makers

Florida DTF 101 frames the journey from curiosity to a repeatable workflow. As a beginner, you’ll want a clear plan that covers DTF printer setup, color management, and the essential steps of the transfer process. This roadmap equips you with beginner DTF tips Florida-style: start small, document every parameter, and keep test garments on hand to verify wash durability and color stability under Florida sun and humidity.

Expect a practical sequence: select the right printer compatible with textiles, install reliable RIP software, print swatches on common fabrics, cure powders, and test transfer results. By following this plan, you’ll reduce waste, improve yield, and build a scalable process whether you’re targeting local markets, online orders, or collaborations with Florida-based boutiques.

DTF Printer Setup and Workspace Optimization in a Florida Climate

Your workspace sets the tone for reliable DTF printing in Florida. A clean, climate-aware setup that includes stable electricity, good ventilation, and a dedicated drying/curing zone will save you from ink bunching and head clogs caused by humidity. In Florida, ongoing climate considerations mean you’ll want dehumidification and air conditioning to keep print quality consistent, regardless of outdoor heat.

Invest in a printer that is known for textile compatibility and pair it with a well-tuned RIP and calibrated printheads. Keep materials organized in moisture-proof containers; store films, powders, and fabrics away from moisture and direct sunlight. With a solid DTF printer setup, you’ll see fewer surprises, faster production, and more repeatable results to meet Florida’s ongoing demand for custom apparel.

The DTF Transfer Process Demystified for Florida Makers

The transfer process starts with design and color management, then moves through printing onto PET film, powder application, curing, and finally transferring to fabric with precise heat and dwell time. For Florida operations, nailing each step matters because heat, humidity, and fabric blends can affect how the image adheres and how colors stay vibrant. A well-executed transfer yields a soft hand feel and durable colorfastness ideal for sun-drenched wear.

Testing is essential: run swatches on fabrics representative of Florida clients, tweak white underbase density, and verify adhesion across different substrates. Fine-tuning the temperatures, pressures, and times helps you avoid issues like cracking or delamination, especially on blends popular in Florida. As you gain experience with the DTF transfer process, you’ll develop a reliable standard operating procedure that scales with orders.

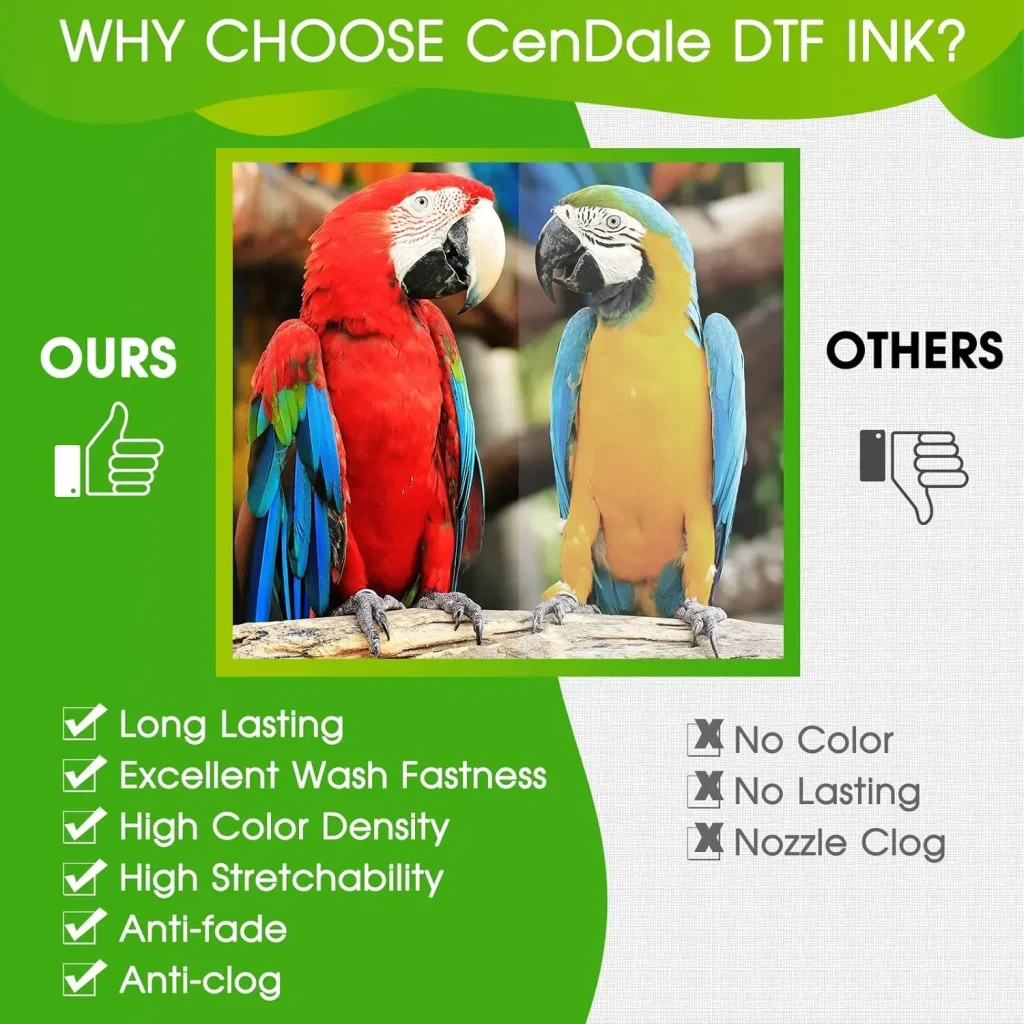

DTF Inks and Media: Choosing Materials for Florida’s Textiles

DTF inks and media form the backbone of output quality. When selecting inks, look for textile-specific formulations that deliver strong wash-fastness and decent lightfastness for Florida sun exposure. The film should be clear, durable, and compatible with your powder adhesion and curing equipment. A quality adhesive powder distributes evenly to ensure a crisp image on a range of Floridian fabrics, from cotton tees to moisture-wicking blends.

Beyond ink and film, plan for curing equipment, post-press care, and storage. In Florida, humidity can affect film storage and powder behavior, so keep materials in sealed containers and test new batches with small runs before a full order. By optimizing DTF inks and media choices, you’ll achieve consistent color, durable transfers, and a reliable production path for Florida clients, including beachwear brands and event sellers.

Frequently Asked Questions

What is Florida DTF 101 and who should start with it for DTF printing in Florida?

Florida DTF 101 is a beginner-friendly guide to Direct-to-Film (DTF) printing tailored for Florida. It explains the technology, equipment, workflow, and climate considerations to help newcomers start a successful DTF printing business in Florida, whether you’re selling beachwear, event apparel, or promo items.

How does the DTF transfer process work, as described in Florida DTF 101?

Florida DTF 101 walks you through the DTF transfer process: design and color management; print onto PET film with the white underbase; apply and cure the adhesive powder; transfer to fabric with the heat press at the recommended settings; and perform finishing checks for durability and washfastness.

What should I know about DTF printer setup in the Florida DTF 101 guide?

Florida DTF 101 emphasizes a clean, climate-aware printer setup: a humidity-controlled workspace, stable power, proper ventilation, a textile-friendly printer with compatible RIP software, and tuned printheads to ensure repeatable results in Florida’s climate.

Which DTF inks and media are recommended in Florida DTF 101?

The guide highlights textile-specific inks, a clear PET film with good release properties, and a quality adhesive powder, all chosen to work with your printer model and to deliver durable, vibrant results on Florida-friendly fabrics.

What beginner DTF tips Florida-style does Florida DTF 101 emphasize?

As beginner DTF tips Florida-style, start small, document parameters, test on representative fabrics, calibrate colors, and consider Florida’s climate for storage and curing to reduce waste and build consistency.

| Topic | Key Points |

|---|---|

| What is DTF Printing and Why It Matters in Florida | – Heat-transfer technique using film, adhesive powder, and heat press; – Produces vibrant colors and soft hand feel; – Works on cotton and blends; – Great for beachwear, event shirts, jerseys, and promotions; – Florida DTF 101 frames tech, benefits, and limits to help decide fit. |

| Setting Up Your Workspace: DTF Printer Setup | – Clean, climate-friendly workspace with ventilation and stable power; room for printer, heat press, and curing area; – Choose a printer compatible with textiles, a quality RIP, and well-tuned printheads; – Manage Florida humidity to prevent ink bunching and clogging; – A thoughtful setup reduces waste and improves repeatability. |

| The DTF Transfer Process: From Design to Finished Garment | – Design and color management; – Print onto PET film with white underbase and color layers; – Apply adhesive powder and cure it; – Transfer to fabric with heat press at recommended temps/times/pressures; – Finish with warm setting, wash tests, and quality checks; – Practice to optimize temperatures and times; – Maintain a consistent procedure for uniform results. |

| Ink, Film, and Media: DTF Inks and Media to Know | – Inks: textile-specific with good color, wash-fastness, and lightfastness; – Film: clear, durable PET film; – Adhesive powder: fine and evenly distributed; – Curing and finishing supplies: proper curing equipment and post-press care; – Quality materials save issues, especially for Florida-based small businesses. |

| Practical Considerations for Florida Climate and Space | – Florida’s humidity, heat, and rain affect printing/storage; – Control humidity with dehumidifiers/AC; store films/powders in sealed containers; ensure proper ventilation during curing and pressing; – Monitor power stability; consider UPS for critical components. |

| Quality Control, Troubleshooting, and Common Pitfalls | – Build a repeatable quality system; – Troubleshoot color mismatch, white underbase density, powder adhesion, cracking, curling, and color bleeding; – Test on representative fabrics and keep a small batch of test garments to refine before scaling. |

| Launching Your DTF Business in Florida: A Step-by-Step Starter Plan | – 4–6 week plan: Weeks 1–2 finalize setup; Week 3 test designs and color management; Week 4 create pricing/packaging/storefront; Weeks 5–6 run a pilot batch and iterate; – Florida-style tips: start small, document parameters, iterate based on feedback. |

| The Bottom Line: Is Florida DTF 101 Right for You? | – DTF in Florida offers fast turnaround, vibrant results, and on-demand flexibility; – Florida DTF 101 provides a foundation from printer setup to transfer, plus ink choices and climate-aware production; – Align with market needs, equipment realities, and hands-on discipline for success in Florida’s print landscape. |

| Conclusion (Key Takeaway) | – Florida DTF 101 sets you up for a well-considered, durable entry into direct-to-film printing; – Focus on essentials: quality equipment and materials, a repeatable transfer process, climate-conscious workspace, and a customer-centric business plan; – You can expand into new product lines and fabrics, or offer on-demand services for Florida-based clients; – Long-term success comes from steady practice, ongoing learning, and a thoughtful approach to every step of the DTF journey. |

Summary

HTML table explaining the key points of the base content in English, followed by a descriptive conclusion optimized for Florida DTF 101.