If you’re venturing into the world of UV DTF Gangheet, you’re about to unlock the potential of cutting-edge printing technology. This innovative approach combines the precision of UV printing with the flexibility of Direct to Film (DTF) methods, allowing for stunning and durable prints on diverse surfaces. UV DTF printing techniques offer versatility that caters to a variety of applications, from custom apparel to promotional items. The benefits of UV printing extend beyond just vibrant colors; they also guarantee longevity and resilience against environmental factors. In this guide, we’ll explore essential gangheet printing tips that will elevate your skills and maximize your print projects.

Exploring the realm of UV DTF printing reveals a treasure trove of possibilities for creatives and entrepreneurs alike. Often referred to as Direct to Film printing, this technique leverages UV inks to produce striking designs on various materials. The adaptability of such custom print techniques means you can achieve remarkable results on everything from fabrics to hard surfaces. Understanding the benefits of UV printing will not only enhance your projects but also improve the overall efficiency of your printing process. Join us as we delve into effective strategies and methods to master the art of Gangheet.

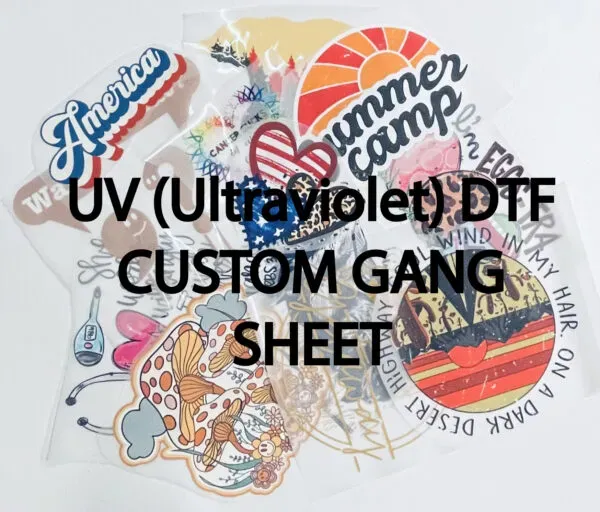

Exploring the Basics of UV DTF Printing Techniques

To fully grasp UV DTF printing, it’s important to understand how it operates at a fundamental level. UV DTF combines the methodologies of Direct to Film printing and UV curing, creating a dynamic approach to design that can achieve intricate patterns and vibrant colors. The initial step in this process involves the careful application of UV inks onto a transfer film. This film, once printed, is then cured with ultraviolet light, which induces fast drying and exceptional durability in the final product. As this technique evolves, mastering these foundational aspects can lead to outstanding results in your output.

Understanding the nuances of UV DTF printing techniques not only enhances your skill set but also broadens your creative possibilities. Each substrate can react differently to the inks depending on its texture, porosity, and color. Therefore, experimentation with various films and inks can yield diverse results, allowing for a high degree of personalization in print outputs. Emphasizing the learning of different trapping methods and layered designs can further elevate the creativity in your printing endeavors.

Benefits of UV DTF Printing for Custom Projects

The benefits of UV DTF printing are numerous, particularly when engaged in custom projects. One significant advantage lies in its exceptional versatility; custom designs can be seamlessly integrated onto a variety of surfaces such as textiles, plastics, and industrial materials. This adaptability makes it an ideal choice for businesses looking to create bespoke promotional materials or personalized products. Furthermore, as industries continually seek innovation in product offerings, UV DTF presents endless possibilities to cater to unique customer demands.

Moreover, UV DTF printing does not compromise on durability. Unlike traditional printing methods, UV DTF hardened prints are more resistant to wear and tear, ensuring that custom designs remain vibrant even under harsh conditions. As businesses aim to deliver lasting quality, opting for UV DTF printing can significantly enhance customer satisfaction. It not only informs potential clients of your commitment to quality but also strengthens brand identity through consistently high-quality custom prints.

Essential Gangheet Printing Tips for Success

As you delve into the realm of UV DTF Gangheet printing, keeping certain tips in mind can enhance your success and efficiency. First, consider fine-tuning your printer settings to accommodate the gangheet method. This involves optimizing ink saturation and print speed, ensuring designs maintain clarity without being overly dense. Continuous tinkering with these settings, coupled with a proactive approach to test prints, will help identify what suits your particular materials best.

Additionally, knowledge of preventive maintenance is crucial. Regular checks on the printer’s components, such as the print heads and UV lamps, help avoid many common issues that can hamper production. Keeping the equipment clean and calibrated ensures longevity, allowing for consistent quality in your gangheet prints. Therefore, integrating a routine of diligence into your printing process not only improves the immediate outputs but also extends the life of your printing equipment.

How to Achieve High-Quality Prints with UV DTF

Achieving high-quality prints using UV DTF hinges on several interrelated factors, including surface preparation, ink quality, and environmental conditions. Properly prepping the substrate is crucial for achieving optimal adhesion; ensuring it’s clean and appropriately treated will significantly impact print quality. The type of ink selected also plays a vital role, since using high-grade UV inks designed for DTF-specific applications results in more vibrant colors and longer-lasting prints.

Furthermore, controlling environmental factors such as humidity and temperature cannot be overstated. These elements can greatly influence the curing stage of printing. Maintaining stability in your workspace minimizes unexpected complications, allowing for reliable production schedules and preserving the integrity of your prints. Implementing these practices sets a solid foundation for producing high-quality UV DTF prints that meet client expectations.

Sustainability in UV DTF Printing Practices

Sustainability is a growing concern in the printing industry, and UV DTF printing offers several eco-friendly advantages. Many manufacturers now formulate UV inks that are significantly less harmful to the environment compared to traditional solvent-based inks. By using water-based inks and energy-efficient curing processes, UV DTF printing aligns with green practices, thereby improving the sustainability of your production process while still achieving impressive output quality.

Incorporating sustainability into your UV DTF printing not only benefits the environment but also enhances your brand’s reputation among environmentally conscious consumers. As businesses increasingly seek to create ‘green’ practices, aligning your operations with sustainable methods can be a key differentiator in a competitive marketplace. It’s essential to communicate these commitments to your clients, showcasing not just high-quality products but a responsible approach to production.

Future Trends in UV DTF Printing Technology

As technology continues to evolve, UV DTF printing is poised for significant advancements in efficiency and output quality. The integration of AI and machine learning into printing processes could optimize printer settings based on specific project requirements, thus enhancing quality while minimizing waste. Staying ahead of these trends will require ongoing education and adaptation to the latest technologies available within the industry.

In addition to machine advancements, the development of new ink formulations and substrates is likely to expand the horizons of UV DTF printing. These innovations promise to further enhance durability and color reproduction, making it possible to produce even more detailed and vibrant designs. For professionals in the field, keeping abreast of future trends can position you as an industry leader, allowing you to leverage new tools and techniques to meet client demands head-on.

Frequently Asked Questions

What is the UV DTF Gangheet technique in printing?

The UV DTF Gangheet technique combines UV printing with Direct to Film (DTF) technology to create vibrant and durable prints on various substrates. This method enables the application of UV inks onto a special transfer film that can adhere to materials like fabrics, ceramics, and metals.

What are the benefits of using UV DTF printing techniques?

UV DTF printing techniques provide numerous benefits, including versatility to print on diverse surfaces, durability against scratches and fading, and environmentally friendly options. This makes UV DTF printing ideal for creating high-quality promotional items and personalized gifts.

How can I optimize my UV DTF Gangheet prints?

To optimize your UV DTF Gangheet prints, ensure thorough surface preparation, select high-quality UV inks, regulate the curing process with appropriate UV light intensity, and maintain consistent temperature and humidity levels during printing.

What are some essential gangheet printing tips for beginners?

Essential gangheet printing tips for beginners include practicing correct surface preparation, utilizing quality inks specifically designed for UV DTF printing, frequently testing different substrates, and maintaining your UV printer for optimal performance.

How do I ensure the durability of my UV DTF prints?

To ensure the durability of your UV DTF prints, focus on using high-quality UV inks, properly cure the prints with the right UV light settings, and protect your printed items from extreme conditions like humidity and high temperatures.

Why should I choose UV DTF printing over other custom print techniques?

Choosing UV DTF printing over other custom print techniques offers advantages such as superior versatility, increased durability of prints, and sustainable printing practices with eco-friendly UV inks, making it an excellent choice for a variety of applications.

| Key Point | Description |

|---|---|

| UV DTF Printing | A merging of UV printing and DTF technology, using UV inks on transfer film for durable prints. |

| Versatility | Applicable to various surfaces like fabrics, ceramics, wood, and metal. |

| Durability | Resistant to scratches, fading, and water, ensuring longevity of prints. |

| Sustainability | Modern UV inks are often environmentally friendly. |

| Surface Preparation | Clean substrates promote better adhesion and print quality. |

| Ink Quality | High-quality UV inks improve vibrancy and adherence. |

| Curing Process Optimization | Fine-tune intensity and exposure times for optimal results. |

| Temperature & Humidity Control | Maintaining optimal conditions ensures consistent print quality. |

| Preventive Maintenance | Regular maintenance keeps UV printers in optimal condition. |

Summary

UV DTF Gangheet is revolutionizing the printing landscape with its innovative blend of durability and versatility. By understanding the key aspects of UV DTF printing, such as surface preparation and ink quality, you can harness the transformative capabilities of this technology. The insights provided within this guide ensure that both novice and experienced printers can achieve outstanding results across various materials and applications. As you explore UV DTF Gangheet further, you will find that mastering this art not only enhances your creative potential but also aligns with sustainable practices in modern printing.