The DTF Gangsheet Builder is revolutionizing the landscape of custom printing, offering innovative solutions for creators and businesses alike. This advanced tool leverages Direct to Film (DTF) printing technology to efficiently produce high-quality designs on various fabrics. By utilizing the gangsheet method, users can print multiple designs simultaneously, maximizing productivity and minimizing material waste. This groundbreaking approach not only enhances the versatility of fabric printing but also caters to the growing demand for personalized products. As we delve deeper into the world of DTF printing, it becomes clear that the DTF Gangsheet Builder is a significant game-changer in the industry.

In the realm of custom designs, tools like the DTF Gangsheet Builder provide essential capabilities for both professional printers and creative enthusiasts. This fabric printing innovation employs the gangsheet technique, which allows for the simultaneous application of multiple images onto textiles, thereby streamlining the production workflow. Direct to Film (DTF) technology enhances the quality and speed of print jobs, making it a favored choice for those seeking efficient and versatile solutions. With the ever-evolving landscape of custom printing, embracing DTF technologies can ensure businesses stay ahead in a competitive market.

The Rise of DTF Printing Technology

The rise of Direct to Film (DTF) printing technology signifies a paradigm shift in the landscape of custom printing. Unlike traditional methods, DTF printing utilizes innovative heat-transfer techniques to produce vibrant, high-resolution designs directly onto fabric. This transition not only enhances the quality but also broadens the design capabilities, allowing for intricate graphics and patterns that were difficult to achieve previously. This cutting-edge technology caters to a wider audience, from hobbyists to large-scale manufacturers looking to meet diverse customer needs.

Moreover, DTF printing stands out for its efficiency and cost-effectiveness. By enabling printers to apply multiple designs from a single setup, it significantly reduces setup time and material usage, ultimately increasing profit margins for businesses. As demand for personalized and unique apparel grows, DTF technology has positioned itself at the forefront of fabric printing, making it a preferred choice for custom merchandise.

Understanding the DTF Gangsheet Builder

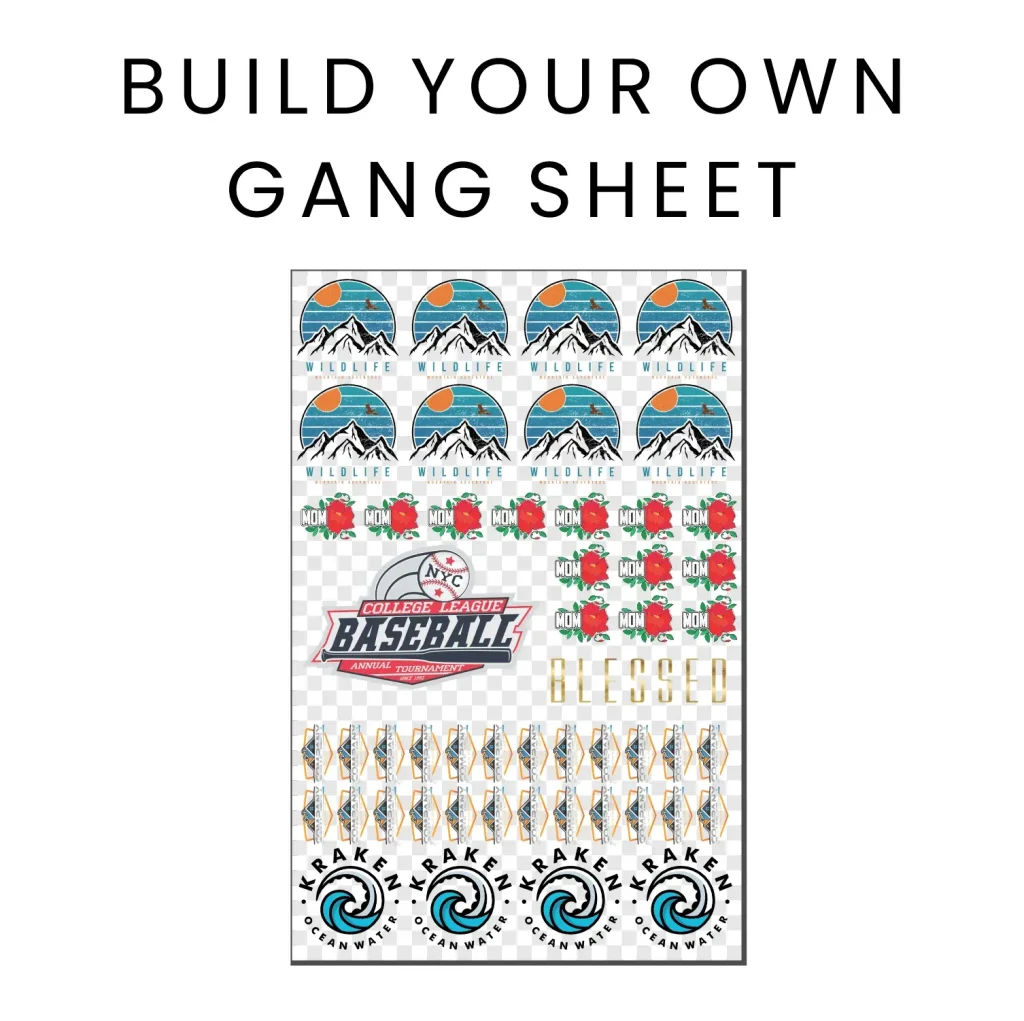

At the core of DTF printing’s efficiency lies the DTF gangsheet builder, a revolutionary tool that optimizes the printing process. This builder allows users to compile various designs on one film sheet, promoting seamless transfer onto different fabrics. The gangsheet method not only minimizes wastage but also maximizes productivity by enabling the simultaneous transfer of multiple designs. This innovation is particularly beneficial for small businesses and startups, as it simplifies the production process and improves output efficiency.

With user-friendly software now available for creating gangsheet layouts, even those with minimal design skills can easily navigate the process. This accessibility empowers businesses to take full advantage of DTF printing capabilities, leading to faster turnaround times and improved customer satisfaction. As more printers adopt the gangsheet method, it is becoming a staple in the custom printing world, reshaping how designs are produced and applied.

Advancements in DTF Printing Technology

The past few years have seen remarkable advancements in DTF printing technology, enhancing both the quality and sustainability of fabric printing. Innovations in ink formulation have introduced eco-friendly alternatives that do not compromise on vibrant color quality or durability. Customers increasingly seek sustainable printing options, and the new ink technologies cater to this demand, making printed fabrics not only visually appealing but also more responsible.

In addition to improved ink formulations, modern DTF printers now incorporate advanced features such as real-time monitoring and smarter user interfaces. These improvements allow operators to oversee the printing process with greater precision, ensuring that every print job meets high standards of quality. As technology continues to evolve, it holds the potential to push the boundaries of what’s possible in DTF printing, further solidifying its role as a leader in the custom printing industry.

Market Trends and Outlook for DTF Printing

As DTF printing gains traction, we observe significant market trends favoring this technology in the custom printing arena. Increasing consumer demand for personalized products drives businesses to adopt flexible printing solutions capable of handling diverse order sizes—from single custom designs to large bulk productions. DTF printing’s ability to deliver quick turnarounds while maintaining quality is a key factor in its rising popularity among consumers who seek specific and unique items.

Industry experts predict that as DTF technology becomes more widely adopted, it will lead to a substantial expansion of the market. The continuous introduction of user-friendly tools and platforms for DTF printing will also democratize access, enabling more entrepreneurs to participate in this thriving landscape. As businesses invest in DTF capabilities, they align themselves with current trends, paving the way for enhanced growth opportunities and competitiveness in the fabric printing sector.

Maximizing Efficiency with DTF Gangsheet Method

The DTF gangsheet method plays a pivotal role in maximizing efficiency within the custom printing workflow. By allowing multiple designs to be printed simultaneously on a single sheet, businesses can significantly reduce both printing time and material costs. This efficiency not only helps in increasing production rates but also ensures that smaller businesses can compete on an equal footing with larger entities that have more resources.

Furthermore, the gangsheet method reduces operational waste, promoting a more sustainable approach to fabric printing. As companies strive to minimize their environmental footprint, leveraging tools like the DTF gangsheet builder becomes essential. By optimizing resource usage and enhancing productivity, businesses can cater to the growing consumer base that values both quality and sustainability.

Business Opportunities in DTF Printing

For aspiring entrepreneurs, the DTF printing method presents numerous business opportunities. With the flexibility to accommodate a range of client needs—from custom apparel to personalized merchandise—DTF technology positions itself as a versatile solution in the custom printing market. The introduction of gangsheet builders further enhances this potential, as they allow entrepreneurs to streamline operations and fulfill orders efficiently.

Investing in DTF technology also means staying ahead of market trends focused on personalization and sustainability. As consumer preferences shift towards unique, high-quality products that reflect individual styles, businesses that utilize DTF printing can attract a diverse customer base. By capitalizing on these trends and employing effective DTF strategies, entrepreneurs can build robust and successful printing ventures in an increasingly competitive landscape.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it work?

The DTF Gangsheet Builder is a tool used in DTF printing that enables users to create layouts for multiple designs on a single film sheet. By utilizing this method, printers can optimize fabric usage, minimize waste, and streamline the transfer process, making it an essential component for efficient custom printing.

How does the DTF printing process differ from traditional fabric printing?

DTF printing is distinct from traditional fabric printing methods, such as screen printing, as it allows for direct application of vibrant designs onto fabrics using heat transfer. This technology supports complex designs without the need for separate setups for each print, enhancing versatility and production efficiency.

What are the benefits of using a DTF gangsheet in custom printing?

Using a DTF gangsheet offers numerous benefits for custom printing, including increased efficiency by allowing multiple designs to be printed simultaneously, reduced material waste, lower production costs, and faster turnaround times on customer orders.

What recent technological advancements are impacting DTF printing?

Recent advancements in DTF printing include new eco-friendly ink formulations that enhance print quality and durability, improved printer interfaces for better user control, and features for real-time job monitoring, all aimed at boosting efficiency and sustainability in fabric printing.

How can small businesses leverage the DTF Gangsheet Builder for growth?

Small businesses can leverage the DTF Gangsheet Builder by maximizing their production capabilities, reducing costs associated with waste, and quickly fulfilling diverse customer orders. By adopting this technology, they can enhance service levels, meet personalized demands, and ultimately drive growth in a competitive market.

What trends are emerging in the DTF printing market?

Emerging trends in the DTF printing market include a growing demand for personalized products, increased adoption of sustainable practices, and a rise in technology-driven solutions that facilitate flexible production—positioning DTF printing as a preferred method in the custom printing industry.

| Key Point | Description |

|---|---|

| Introduction to DTF Printing | Discusses how DTF printing has transformed custom design production, enhancing versatility and efficiency through innovations like the DTF gangsheet builder. |

| What is DTF Gangsheet Builder? | A tool that allows printing multiple designs on a single film sheet, streamlining production and reducing waste. |

| Efficiency Gains | DTF gangsheet builders optimize fabric usage and increase productivity by enabling users to layout multiple designs efficiently. |

| Technological Improvements | New ink formulations, improved printers, and user interfaces enhance print quality and operational control. |

| Market Trends | Growing recognition of DTF in various industries due to demand for personalized products and sustainable options. |

| Business Insights | Investing in reliable equipment and aligning with reputable suppliers is key for success in the custom printing market. |

Summary

DTF Gangsheet Builder is revolutionizing the landscape of custom printing by enhancing efficiency, sustainability, and quality. This innovative approach to Direct to Film (DTF) printing allows users to maximize their designs on a single sheet, streamlining production processes and reducing waste. As technology continues to advance, including eco-friendly inks and improved printer interfaces, businesses can better cater to the growing demand for personalized products. The rise of DTF printing showcases a remarkable opportunity for entrepreneurs in the custom printing arena, where adopting these advancements can lead to significant growth and increased customer satisfaction.