Direct-to-Film printing in Florida is transforming how brands, small shops, and hobbyists approach apparel decoration in 2025. As consumer demand for on-demand, customized garments grows, Direct-to-Film printing offers a practical, scalable solution that blends vibrant color, durable transfers, and a straightforward DTF printing workflow. This approach provides flexibility across fabrics and batch sizes, with a workflow that many Florida operators find easier to manage than older methods. When planning a DTF setup, considering overall costs—including equipment, consumables, and maintenance—helps shops forecast investment in the Florida market. Choosing the right transfer film and optimizing curing, finishing, and post-processing are crucial for consistent, long-lasting results in humid Florida conditions.

Seen through a Latent Semantic Indexing lens, this film-based garment transfer technology operates as a heat-press workflow that moves design from a printed carrier sheet to fabric. Other common descriptors include transfer-sheet printing, carrier-film systems, and color-rich, heat-applied designs that perform across cotton, blends, and performance fabrics. In practical comparisons, you’ll often hear people discuss DTF vs DTG, focusing on where the image travels and how the fabric responds rather than ink-on-textile basics. As you evaluate suppliers and equipment, look for terms about transfer film quality, adhesive layers, and curing control to broaden your understanding beyond acronyms and build a Florida-ready production plan.

Direct-to-Film printing in Florida: A scalable model for on-demand apparel

Direct-to-Film printing in Florida offers on-demand apparel personalization with vibrant color and durable transfers. It enables brands, small shops, and hobbyists to scale production without committing to large minimum runs. By printing to a transfer film instead of directly to fabric, operators can pre-press, test color, and tile designs for larger orders. The Florida market—with its festivals, schools, sports teams, and boutique brands—benefits from quick turnarounds and flexible job sizing.

With a workflow centered on transfer films, Florida businesses can mix fast turnaround with high color fidelity across cotton, blends, and poly fabrics. The film system is compatible with a range of substrates and finishing options, expanding opportunities beyond basic T-shirt prints to hats, bags, and team jerseys. To succeed in the Sunshine State, it’s important to manage humidity during curing and ensure consistent film handling in warm conditions.

DTF vs DTG: how to choose the right method for Florida shops

DTF and DTG represent two pathways to garment decoration, each with strengths and tradeoffs. DTG prints directly onto fabric, often excelling on smooth cotton surfaces with a soft hand, while DTF prints onto a transfer film that is then applied with heat. This separation can impact throughput, maintenance, and substrate compatibility.

For Florida shops weighing the options, consider your typical fabrics, run sizes, and lead times. If you frequently switch between cotton tees and polyester blends, DTF offers more predictable color and adhesion across fabrics. If you focus on premium, single-fabric items with a soft hand, DTG may be preferable. Also factor in DTF printer costs as part of the long-term economics when comparing equipment and consumables.

DTF printing workflow: from design to finished garment

DTF printing workflow guides every stage from concept to completion. Start with design and color management, ensuring you use calibrated monitors and appropriate color profiles to minimize shifts on film. Next, print onto the transfer film with precise ink density and alignment, then prepare for powdering and curing.

After printing, a fine adhesive powder is applied to the film and cured before transfer. This powdering step is critical for adhesion and durability, and Florida’s humidity can influence how evenly the powder sets. Finally, transfer the design to fabric with heat and pressure, trim excess film, and perform quality checks to verify color accuracy and edge sharpness.

DTF transfer film and materials: selecting film, adhesive, and powders for Florida conditions

Choosing the right DTF transfer film, adhesive, and powders is central to consistent results. Look for films with uniform thickness, good release properties, and minimal static, along with adhesives tuned for robust adherence across fabrics and multiple wash cycles. For Florida operations, select materials that tolerate heat and humidity without compromising transfer quality.

In addition to film quality, evaluate the chemistry of the adhesive and the grinding of the powders, which influence transfer durability and washfastness. Pre-treatment steps, if needed, should align with the film system you’re using. Testing on representative swatches helps ensure reliable performance across cotton, blends, and performance fabrics common in Florida markets.

DTF printer costs and total cost of ownership for Florida businesses

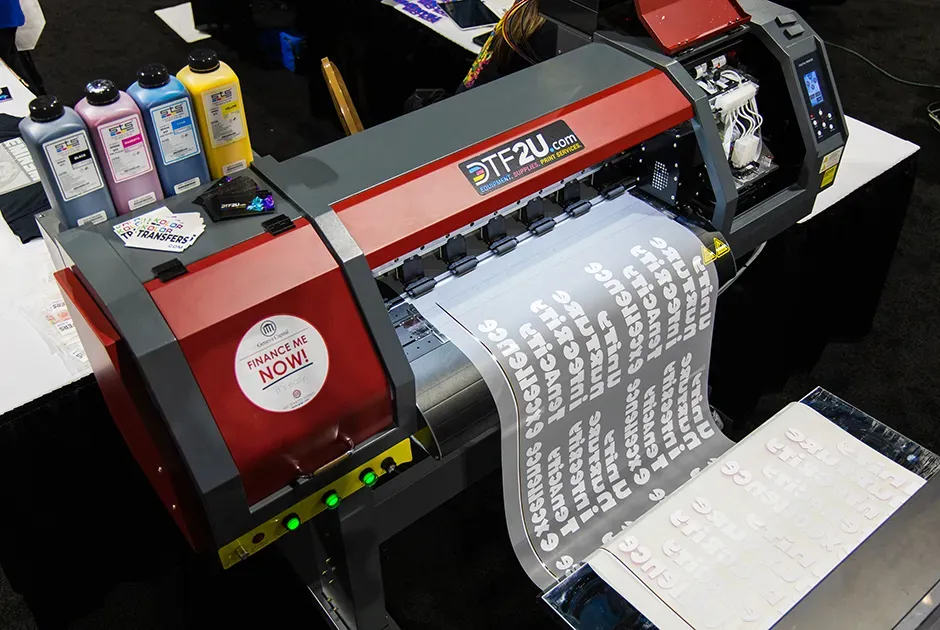

Understanding DTF printer costs is essential for budgeting a Florida production setup. Entry-level DTF printers can range from a few thousand dollars to well over ten thousand, depending on features, print width, and ink systems. When evaluating a Florida purchase, consider the total cost of ownership including maintenance, consumables, and potential service plans.

Ongoing expenses include inks, transfer films, and adhesive powders, as well as routine maintenance and parts. Utilities, climate control, and workspace setup are additional considerations in Florida’s warm, humid environment, all of which impact print quality and equipment longevity. Planning for these costs helps Florida-based shops maintain steady production and reliable turnarounds over time.

Frequently Asked Questions

What is Direct-to-Film printing in Florida and why should I consider it for on-demand apparel?

Direct-to-Film printing in Florida uses a transfer film printed with special inks, then heat-pressed onto fabric to create durable, vibrant designs. It works well on cotton, blends, and poly fabrics, and is scalable for quick-turnaround orders—making it attractive for Florida brands, shops, and hobbyists. When evaluating this method in the Sunshine State, consider humidity and heat during curing and finishing, which can influence adhesion and wash durability.

Direct-to-Film printing in Florida vs DTG: which is better for different fabrics?

DTF printing in Florida and DTG (direct-to-garment) have different strengths. DTF uses a transfer film, enabling excellent color on a wide range of fabrics (including blends and poly) and can offer more consistent results across fabrics, while DTG tends to shine on smooth cotton surfaces. For Florida environments, DTF’s predictable adhesion and versatility often translate to more reliable results across varied fabrics and climate conditions.

What does the DTF printing workflow look like for a Florida shop?

The DTF printing workflow starts with design and color management, followed by printing on the transfer film, powdering and curing, transferring to fabric with heat and pressure, and finishing checks. In Florida, managing humidity during powdering and curing is important to prevent clumping and ensure consistent adhesion, while maintaining calibrated color profiles helps ensure accurate brand colors across orders.

What should Florida printers look for in DTF transfer film and related materials?

Florida printers should prioritize consistent, high-quality DTF transfer film with reliable release properties, a suitable adhesive system, and powders that perform well under heat and humidity. Since Florida’s climate can affect curing and adhesion, select films and powders that maintain performance in humid environments and align with your pre-treatment and post-press finishing steps for durable, wash-fast transfers.

How should I think about DTF printer costs and ongoing expenses in Florida?

DTF printer costs include the upfront price of the printer, inks, transfer films, and adhesive powders, plus ongoing maintenance and parts. In Florida, factor in utilities, climate control, and potential taxes or shipping considerations that affect total cost of ownership. Plan for recurring expenses based on your production volume to ensure steady profitability while keeping equipment well maintained for reliable Florida-based production.

| Topic | Key Points |

|---|---|

| What Direct-to-Film (DTF) is | DTF uses a transfer film printed with specialized inks; heat and pressure transfer the image to fabric, delivering vibrant, durable results on cotton, blends, polyester, and select non-apparel substrates. |

| DTF vs DTG differences | Process flow: DTG prints directly on fabric; DTF uses a transfer film. Material compatibility: DTG favors cotton; DTF handles a broader range including blends and polyesters. Color/texture: DTF often offers more predictable color across fabrics. Durability and care: with proper curing, DTF transfers show strong washfastness; climate in Florida can influence outcomes. |

| DTF workflow: design to finished garment | 1) Design and color management; 2) Printing on transfer film; 3) Powdering and curing; 4) Transfer to fabric; 5) Finishing and quality checks. |

| DTF transfer film and materials | Choose films with consistent thickness and high release; ensure adhesive and powders suit a variety of fabrics and wash cycles. In Florida, select materials that perform well under heat and humidity, and align pre-treatment and post-press finishing with the film system. |

| DTF printer costs and ongoing expenses | Printer costs vary (entry-level to advanced). Florida taxes/shipping affect upfront investment. Ongoing costs include inks, transfer films, adhesive powders, maintenance, and utilities. Plan for total cost of ownership and climate-control needs. |

| Quality control and color management | Color management is essential: calibrate monitors, use ICC profiles, and test on representative fabrics. Build a library of fabric proofs to reduce production guesswork; account for substrate variability (cotton, blends, performance fabrics). |

| Practical tips for Florida printers | Preflight checks, climate control (stable humidity in curing and powdering areas), consider equipment overlap (DTF with other processes), plan production schedules with buffers, and establish QC rituals for every run. |

| Common challenges and solutions | Poor adhesion: verify film quality and curing; Color shifts: calibrate printers and test on fabrics; Dust/contamination: maintain a clean work environment; Powder clumping: manage humidity and proper drying steps. |

| 2025 trends and opportunities in Florida | Smarter inks, more durable adhesives, and improved transfer films. Florida shops can leverage on-demand ordering, faster setup for small runs, and better color fidelity and wash durability. Expect growing adoption among small studios and Florida-based brands as films and printers become more affordable. |

Summary

Direct-to-Film printing in Florida is transforming how brands, small shops, and hobbyists approach on-demand apparel decoration in 2025. As consumer demand for customized garments grows, DTF offers a practical, scalable workflow with vibrant color, durable transfers, and flexibility across fabrics. This guide summarizes what DTF is, how the process works, key comparisons with DTG, workflow steps, materials, costs, quality control, and practical Florida-focused considerations to help you start or optimize a Florida-based DTF operation.