DTF transfers, or Direct-to-Film transfers, are revolutionizing the custom apparel industry with their ability to create vibrant and high-resolution prints that cater to diverse fabric types. This cutting-edge DTF printing technology eliminates many of the limitations found in traditional printing methods, allowing businesses to meet the growing demand for unique designs and personalization. By leveraging quality DTF transfer materials and mastering the DTF printing processes, companies can ensure their prints not only look stunning but also stand the test of time through wear and washing. In this guide, we will delve into what makes DTF transfers a game-changer for custom textile printing, exploring the intricacies of the technology, material selection, and design considerations. Join us as we unlock the secrets to successfully integrating DTF transfers into your business model.

Direct-to-Film printing, commonly referred to as DTF printing, is a state-of-the-art process that allows for the application of intricate designs onto various textile surfaces. This innovative approach harnesses advanced techniques to produce eye-catching graphics that can significantly enhance apparel offerings. By utilizing specialized DTF transfer materials and focusing on the nuances of the DTF printing process, businesses can achieve exceptional results that captivate consumers. In this article, we will explore the essential elements that contribute to successful Direct-to-Film transfers, providing insights into technology advancements, material quality, and workflow optimization. As we navigate through the world of DTF printing, you’ll discover how to elevate your custom apparel business and keep pace with market trends.

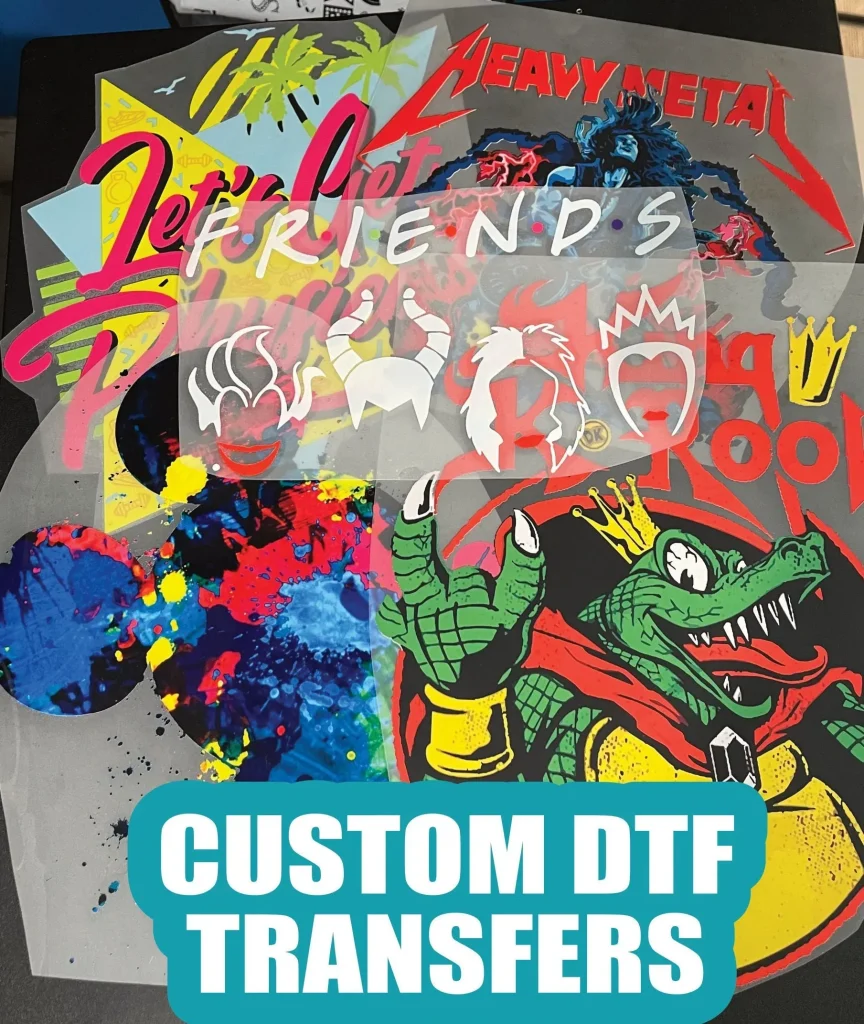

Understanding DTF Transfers in Apparel Printing

Direct-to-Film (DTF) transfers are revolutionizing the way businesses approach textile printing, offering a unique advantage in creating custom apparel. By printing designs onto a special film, businesses can achieve intricate and vibrant graphics that are then transferred onto various fabric types with the application of heat and pressure. This method stands out from traditional printing techniques, as it simplifies the process while enhancing the quality of the final product. The high-resolution capabilities of DTF printing ensure that even the most detailed designs can be reproduced with stunning clarity and color accuracy.

As DTF printing technology gains traction, it presents significant benefits for those in the apparel industry. Designers are now able to push creative boundaries, as the method allows for more complex patterns and vibrant color schemes that truly capture consumer attention. Furthermore, DTF transfers are increasingly recognized for their versatility, as they can be applied to diverse fabrics, whether it be cotton, polyester, or blends. This adaptability makes DTF technology an asset for businesses looking to diversify their product offerings in a competitive market.

Advanced Technology in DTF Printing

Recent advancements in DTF printing technology have significantly transformed production capabilities within the custom apparel sector. Innovative equipment developments by leading manufacturers have enhanced print quality and operational efficiency. For example, modern DTF printers are designed to optimize ink deposition and color precision, enabling businesses to produce sharp details and vibrant prints at improved speeds. This technological progress allows apparel companies to respond quickly to market demands without sacrificing quality.

Moreover, the integration of digital workflows has become a staple in contemporary DTF setups, facilitating smoother transitions from design to final product. By incorporating user-friendly software for design digitization and print management, businesses are streamlining their processes and reducing turnaround times. Such improvements not only enhance productivity but also empower creative teams to experiment with their designs, pushing them further in capturing the unique preferences of consumers in the apparel market.

Choosing Quality Materials for DTF Transfers

The selection of quality materials plays a pivotal role in the success of DTF transfers. High-quality PET films, specifically engineered for compatibility with DTF inks, are essential for optimizing adhesion and producing prints that endure washing and wear. Using subpar materials can lead to various issues, such as fading or delamination, ultimately diminishing the appeal of the custom apparel. Thus, investing in reputable suppliers for DTF transfer materials is crucial for businesses aiming for long-term success.

In addition, the choice of inks is equally important in the DTF printing process. High-performance inks designed for DTF applications ensure vibrant color output and durability on fabric. Companies must prioritize the procurement of materials that not only meet quality standards but also align with their specific printing needs. By doing so, they can minimize risks associated with poor-quality prints and enhance customer satisfaction, paving the way for repeat business and referrals.

Strategies for Optimizing the DTF Printing Process

Achieving optimal results with DTF transfers hinges on the right equipment and workflow optimization. Investing in high-quality heat press machines ensures even pressure and precise temperature control, which are vital for successful transfers. Inadequate equipment can lead to uneven application, adversely affecting print quality and longevity. Consequently, businesses must prioritize the right tools to enhance the overall printing experience and final product integrity.

In parallel, establishing streamlined production workflows is crucial for maximizing efficiency. By deploying lean manufacturing principles and organizing workstations logically, businesses can minimize bottlenecks and maintain an effective production line. Regularly evaluating and adjusting workflow processes can help teams adapt to new challenges, allowing them to sustain high output levels while ensuring quality standards remain unyielded.

Designing for Success in the DTF Market

Crafting eye-catching designs is a critical aspect of maximizing the potential of DTF transfers. Successful designers focus on vibrant colors, bold designs, and intricate details, which can elevate the overall appeal of custom apparel. Vector graphics are particularly advantageous for DTF printing, as they remain sharp and scalable without quality loss, ensuring clarity in any size. This attention to detail not only attracts customers but also reinforces a brand’s identity in a crowded marketplace.

Moreover, staying ahead of design trends is essential for capturing consumer interest and driving sales. As trends evolve, businesses must be proactive in creating unique, personalized designs that resonate with their target market. By continuously researching and adapting to consumer preferences, apparel companies can ensure their DTF products stand out, thereby solidifying their presence in the competitive landscape of custom printing.

Embracing Market Trends and Opportunities in Custom Apparel

The surge of e-commerce presents a robust opportunity for businesses specializing in custom apparel, particularly through the implementation of DTF printing. As online shopping continues to rise, the demand for unique designs tailored to specific consumer preferences is at an all-time high. Companies that can effectively leverage DTF technology to create distinctive and appealing products are well-positioned to capitalize on this growing market, attracting a wider customer base and stimulating sales.

Additionally, agility in production is vital for seizing opportunities within the fast-paced custom apparel landscape. Businesses must remain vigilant, continuously assessing consumer needs and trends to pivot their offerings effectively. By embracing a culture of innovation and flexibility, companies can navigate the competitive waters of the custom printing industry, utilizing the advantages of DTF printing to deliver top-notch products that meet the evolving desires of consumers.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve printing images onto a special film that is then heat-pressed onto various textile surfaces. This process allows for high-resolution graphics and is particularly popular in custom apparel manufacturing, providing vibrant and detailed designs.

What materials are essential for successful DTF transfers?

For optimal DTF transfers, using high-quality PET films and DTF inks is crucial. These materials ensure effective adhesion to fabrics and enhance the durability of prints against washing and wear, preventing issues like fading and peeling.

How has DTF printing technology advanced in recent years?

Recent advancements in DTF printing technology include improved equipment from manufacturers like Epson and Mimaki, which allow for quicker production of stunning prints. Enhanced digital workflow integration also streamlines the design and management processes, increasing overall efficiency.

What are some best practices for achieving high-quality DTF transfers?

To achieve high-quality DTF transfers, invest in precise heat press machines, select high-grade materials, and optimize production workflows. Additionally, focusing on vibrant, well-crafted designs using vector graphics can significantly enhance the final output.

How can businesses tap into the growing demand for custom apparel using DTF transfers?

Businesses can harness the rising demand for custom apparel by leveraging DTF transfers to create unique and personalized designs that appeal to consumers. Staying agile and innovative in design can help capture market trends and boost sales in the e-commerce space.

What training resources are available for mastering DTF printing processes?

Training resources for mastering DTF printing processes include workshops, online courses, and comprehensive guides provided by DTF technology manufacturers and industry experts. Investing in staff education ensures a skilled workforce capable of producing high-quality DTF transfers.

| Key Points |

|---|

| What are DTF Transfers? DTF (Direct-to-Film) transfers print designs onto a film which is then transferred onto textiles using heat and pressure, allowing for high-quality, durable prints. |

| Technology Advancements: Involves cutting-edge equipment from brands like Epson and Mimaki that provide superior print quality and fast production times. |

| Material Selection: Quality of inks and films is essential. High-grade PET films ensure durability and adhesion. |

| Process Optimization: Right equipment like precision heat presses and an efficient workflow enhance print quality and reduce costs. |

| Design Considerations: Using vibrant, high-quality vector graphics is crucial for successful DTF transfers. Designs must align with market trends. |

| Market Trends & Opportunities: The growth of e-commerce presents opportunities for businesses to leverage DTF transfers for customized apparel. |

| Training and Expertise: Investing in workforce training on DTF techniques is essential for maintaining quality and improving production efficiency. |

Summary

DTF transfers are revolutionizing the custom apparel industry by allowing businesses to produce stunning, high-quality prints quickly and effectively. As companies strive to adapt to evolving consumer demands, understanding the intricacies of DTF transfers becomes crucial. Emphasizing high-quality materials, efficient processes, and excellent design, businesses can elevate their competitive edge in the saturated market. By continually training and empowering their workforce, they can fully harness the advantages that DTF transfers bring, ensuring they remain leaders in providing personalized products that resonate with customers.