In the dynamic world of custom printing, DTF transfers, or Direct-to-Film printing, are rapidly emerging as a game-changer for apparel production. This cutting-edge technology is not just about transferring designs; it embodies a revolution that blends creativity with practicality, catering to the growing demand for personalized fashion. Businesses are increasingly recognizing the advantages of DTF transfers, which offer incredible versatility, high detail, and durability. As the trend for on-demand printing rises, it’s clear that DTF printing technology is shaping the future of custom apparel and sustainable printing practices. Exploring the benefits of DTF transfers reveals a pathway to innovation that can elevate business offerings and environmental responsibility alike.

In recent times, the realm of custom printing has witnessed the rise of innovative methods such as Direct-to-Film transfers, showcasing how creativity meets technological advancement. Known for their adaptability and superior print quality, these transfer techniques allow for intricate designs on various fabrics, catering to diverse consumer preferences. This approach not only affirms the trend of print on demand but also emphasizes sustainable printing practices that appeal to eco-conscious audiences. As custom apparel businesses strive to stay competitive, understanding the potential of DTF printing technology will be crucial in harnessing its benefits. The growing inclination towards personalized garments underscores the importance of embracing such advancements in the custom printing landscape.

Understanding the Basics of DTF Printing Technology

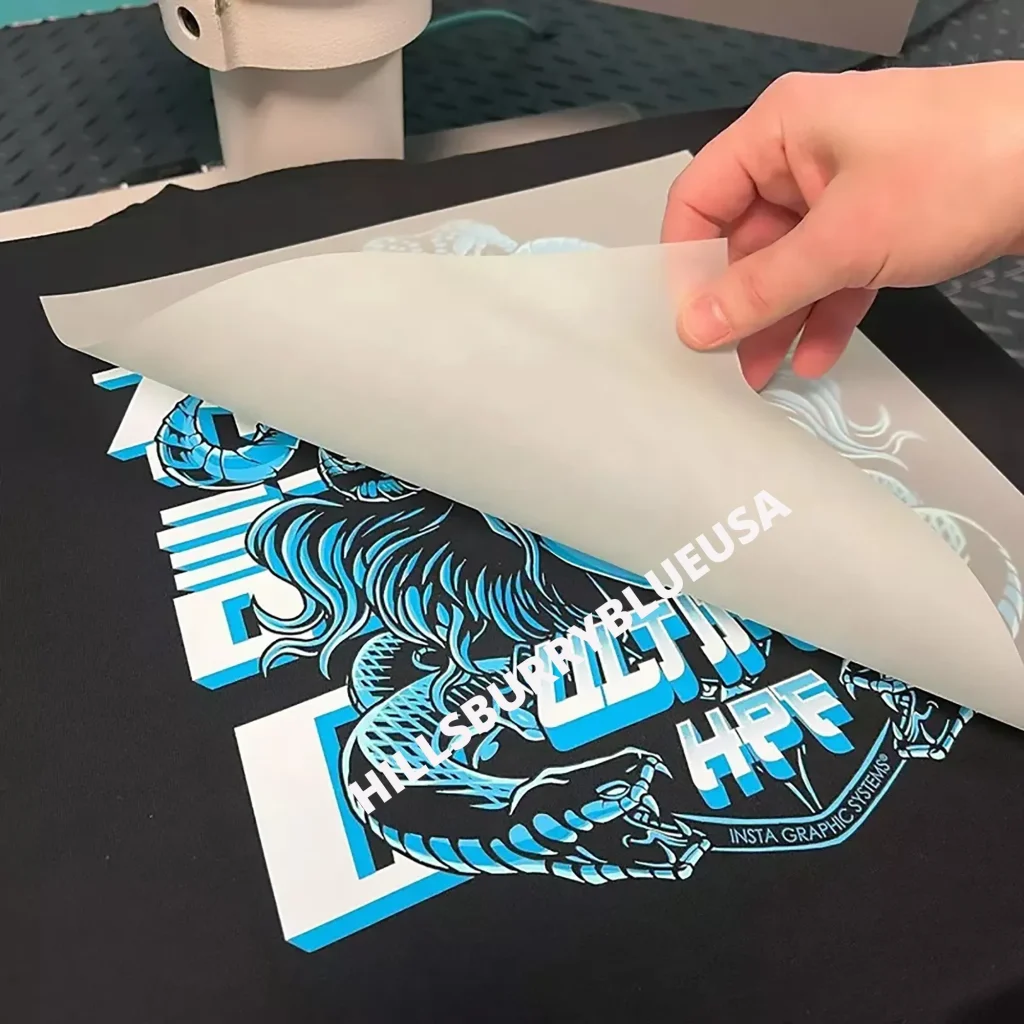

Direct-to-Film (DTF) printing technology is an innovative method that allows designers to transfer their creations onto various fabrics with precision and flair. Unlike direct-to-garment (DTG) printing, which relies heavily on the texture and composition of the fabric, DTF transfers utilize a film that acts as an intermediary. This film is printed with special inks and then heat-pressed onto the chosen material, making it a desirable option for businesses looking to achieve high-quality prints in diverse mediums.

The process begins with a digital design that is printed onto a specially coated film. After the print process, a powder adhesive is applied, and the garment is heated to bond the design permanently. This technique not only ensures vibrant colors but also allows for intricate details, attracting businesses that prioritize quality in their product offerings. As brands continue to evolve and seek technological advancements, DTF printing is solidifying its position as a favored method in custom printing.

The Advantages of DTF Transfers in Custom Apparel

One of the significant advantages of DTF transfers is their versatility, allowing for high-quality prints on varied fabric types including cotton, polyester, and blends. This capability is particularly appealing to custom apparel businesses, enabling them to offer a wider range of products from t-shirts to accessories without switching printing techniques. The flexibility of DTF also means that businesses can swiftly adapt their offerings, responding to current trends and customer demands with ease.

Furthermore, DTF transfers provide excellent color vibrancy and detail, which are critical in today’s competitive market. High-resolution capabilities mean that even complex designs can be replicated accurately, satisfying the aesthetic requirements of brands and individual creators alike. This detailed result not only enhances the visual appeal of products, boosting sales potential, but also reinforces a brand’s commitment to quality craftsmanship.

Cost-Effectiveness of DTF Transfers for Businesses

In the realm of custom printing, cost-effectiveness is a primary consideration, especially for startups and small businesses. DTF printing often incurs lower material costs compared to traditional methods like DTG, making it an attractive option for those looking to create custom apparel in smaller quantities. Since DTF allows for lower minimum orders, businesses can test out unique designs and gauge customer interest without the financial burden often associated with larger runs.

This financial flexibility enables companies to explore a wider variety of custom product offerings without compromising on quality. By reducing overhead costs related to bulk orders and inventory management, businesses are empowered to innovate and expand their product range more freely, ultimately enhancing profitability and market presence.

Durability and Longevity of DTF Prints

Durability is a fundamental concern for consumers purchasing custom apparel, and DTF transfers excel in this area. The process creates prints that withstand multiple washes, maintaining color vibrancy and print integrity over time. This resilience makes DTF a reliable choice for businesses looking to reassure customers about their investment in quality products.

Furthermore, the combination of strong adhesive properties and high-quality inks ensures that designs remain intact and visually appealing even after extensive use. The longevity of DTF prints not only satisfies customer demands for durability but also allows brands to build a reputation for reliably high-quality apparel, directly influencing repeat purchases and customer loyalty.

Sustainable Printing Practices with DTF Technology

As the printing industry faces increasing pressure to adopt sustainable practices, DTF printing is emerging as a promising solution. Many inks used in DTF processes are water-based, which significantly reduces the harmful environmental impact associated with traditional solvent-based inks. This eco-friendly approach meets the growing consumer demand for sustainable products, making DTF printing an appealing choice for businesses looking to align with green initiatives.

Incorporating sustainability into business models not only attracts environmentally conscious customers but also enhances a brand’s image in an increasingly competitive market. By choosing DTF printing, companies can contribute to the reduction of waste and pollution, ensuring that their production processes are not just economically viable but also ethically responsible.

Market Trends and Future of DTF Printing

The custom printing landscape is rapidly evolving, and DTF printing is at the forefront of this change. Recent market analyses show a significant uptick in consumer demand for personalized products, largely driven by advancements in printing technology. Businesses that adopt DTF transfers gain a competitive edge by leveraging innovative techniques to meet shifting consumer preferences.

As the adoption of DTF technology increases, it is poised to reshape the custom apparel market significantly. Companies that embrace these trends can not only enhance their offerings but also tap into new consumer bases interested in high-quality, bespoke products. The future of printing is closely intertwined with innovations in DTF technology, emphasizing both customization and sustainability as central themes.

Frequently Asked Questions

What are DTF transfers and how do they work in custom printing?

DTF transfers, or Direct-to-Film transfers, are an innovative custom printing method where designs are printed onto a special film and then heat-pressed onto various fabrics. This technology allows businesses to achieve high-quality prints on materials such as cotton, polyester, and mixed fabrics, making it a versatile choice for custom apparel.

What are the main advantages of DTF transfers in comparison to other printing methods?

The main advantages of DTF transfers include their versatility across different fabric types, cost-effectiveness for small production runs, excellent vibrancy and detail in prints, and durability through multiple washes. Additionally, DTF printing often utilizes water-based inks, aligning with sustainable printing efforts, making it an appealing choice for eco-conscious brands.

How does DTF printing technology support sustainable printing practices?

DTF printing promotes sustainable printing by using water-based inks that reduce harmful environmental impacts associated with traditional solvent-based inks. By adopting DTF transfers, businesses can meet growing consumer demand for eco-friendly products, appealing to a market that prioritizes sustainability.

Can DTF transfers be used for print on demand services?

Yes, DTF transfers are ideal for print on demand services. Their cost-effectiveness allows businesses to produce smaller quantities without significant financial strain. This flexibility enables companies to test new design ideas and personalize products, catering to individual customer preferences in the custom printing market.

What types of products can be created using DTF printing technology?

DTF printing technology offers the ability to create a wide range of products including custom apparel such as t-shirts, hoodies, and caps, as well as accessories like bags and patches. Its versatility extends across different materials, making it a valuable technique in the custom printing landscape.

Is the initial investment for DTF printing equipment high?

Yes, the initial investment for quality DTF printing equipment can be substantial. However, the long-term benefits, such as lower material costs and higher print quality, can offset this expense. Businesses must weigh the initial costs against the potential for expanded product offerings and market reach when considering DTF transfers.

| Key Aspect | Description |

|---|---|

| What are DTF Transfers? | A printing method where designs are printed on film and heat-pressed onto various fabrics. |

| Versatility | Can be used on various materials such as cotton, polyester, and more. |

| Cost-Effectiveness | Lower material costs, making it accessible for small businesses. |

| High Detail and Color Vibrancy | Produces intricate designs with vibrant colors. |

| Durability | Offers excellent washability and longevity for designs. |

| Environmental Considerations | Some inks are water-based, reducing environmental impact. |

| Market Trends | Growing demand for personalized products is increasing DTF’s popularity. |

| Limitations | Initial investment can be high, and quality control is essential. |

Summary

DTF transfers represent the future of custom printing, providing a flexible, cost-effective solution for creating unique apparel. As this innovative technology continues to evolve, it caters to a growing consumer base eager for personalized products. The advantages such as versatility, high detail, and durability make DTF an attractive option for businesses looking to stand out in the competitive market. Furthermore, with increasing consideration for sustainability, DTF printing aligns well with eco-friendly practices, ensuring it stays relevant in the changing landscape of custom printing.