In the bustling landscape of custom apparel production, the DTF Gangsheet Builder has emerged as a game-changing tool for creatives and entrepreneurs alike. Harnessing the power of DTF (Direct to Film) printing technology, this innovative builder simplifies the design process, enabling users to produce high-quality transfers with ease. As businesses seek to elevate their branding through unique designs, understanding DTF production methods becomes essential. The DTF Gangsheet Builder not only streamlines the workflow but also enhances graphic design for DTF, making it accessible to users of all skill levels. Join us as we explore the myriad benefits of this technology and how it can transform your custom printing endeavors.

Modern custom printing is revolutionized by tools like the DTF Gangsheet Builder, also known as Direct to Film printing systems. This advanced technology facilitates seamless design transformations onto fabric, making it an invaluable resource for apparel manufacturers. The adaptability of DTF printing solutions allows for diverse applications in the fashion and promotional goods industries. With the integration of user-friendly interfaces and enhanced production efficiency, mastering these systems is now more achievable than ever. Let’s dive deeper into how these innovative tools shape the future of clothing production and branding.

The Benefits of DTF Printing in Custom Apparel

DTF (Direct to Film) printing has revolutionized the custom apparel industry, offering numerous advantages over traditional methods. One of the primary benefits of DTF printing is its ability to produce vibrant colors and sharp details on a variety of fabrics. Custom apparel businesses can leverage this technology to create intricate designs that stand out from the competition. Additionally, the DTF process allows for flexibility in production, whether it’s bulk orders or smaller runs, making it ideal for businesses that cater to changing consumer demands.

Another significant advantage of DTF printing is its cost-effectiveness. Unlike screen printing, which often requires extensive setup and minimum order quantities, DTF allows businesses to print on-demand. This capability reduces waste and overproduction, aligning with sustainable practices that many consumers now prefer. Moreover, with the efficient workflow provided by tools like the DTF Gangsheet Builder, businesses can streamline their operations, ultimately increasing productivity and profitability.

How the DTF Gangsheet Builder Enhances Production

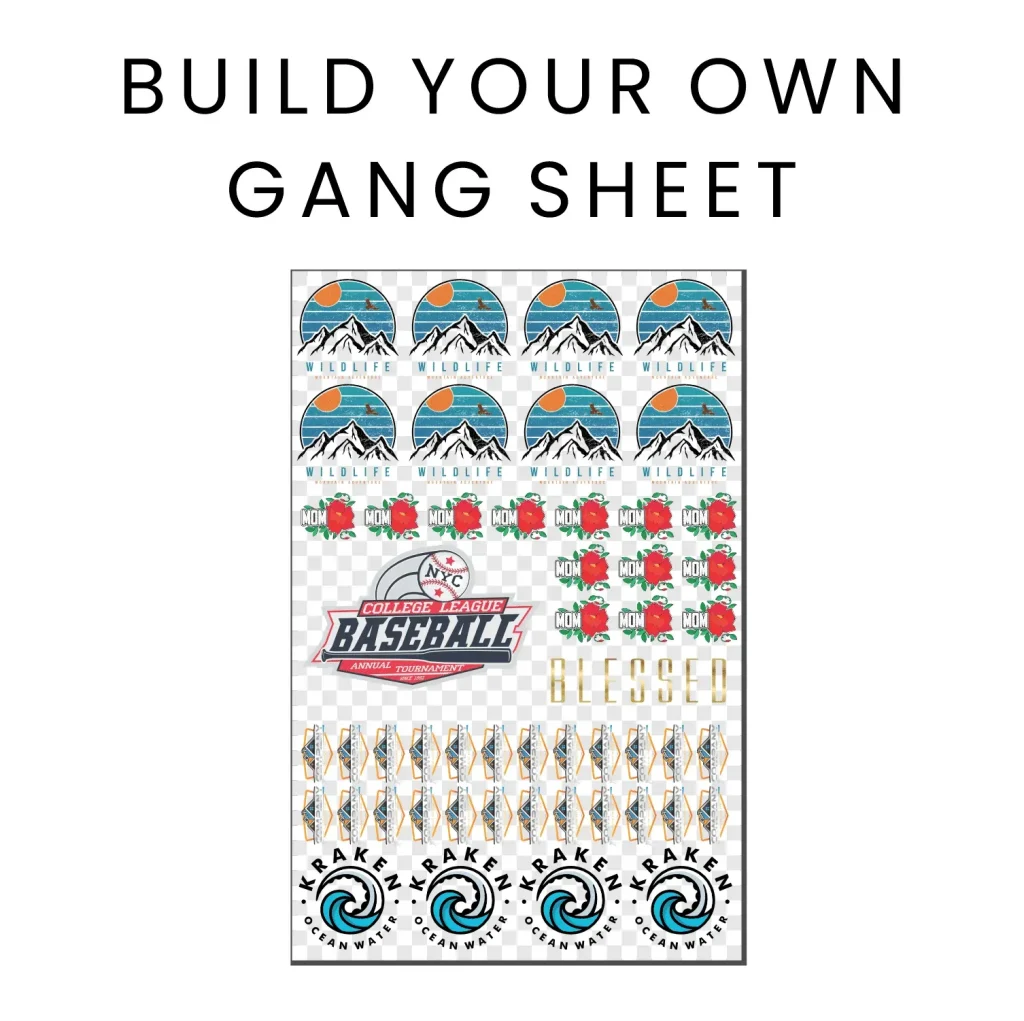

The DTF Gangsheet Builder plays a crucial role in enhancing the efficiency of custom apparel production. By allowing users to assemble multiple designs on a single sheet, this tool minimizes film waste and optimizes ink usage. This innovation not only saves costs but also speeds up the printing process, enabling businesses to fulfill orders more rapidly. Furthermore, the ability to print different designs in one go caters to diverse customer requests for personalized items, thus expanding the market for custom apparel brands.

In addition to increasing production efficiency, the DTF Gangsheet Builder incorporates advanced features that simplify the design process. With tools for automatic color management and density adjustments, even those new to DTF technology can achieve professional-quality results. The user-friendly interface and educational resources available online ensure that users—from novices to experienced printers—can quickly learn how to maximize the capabilities of the DTF Gangsheet Builder, enhancing their overall production experience.

Key Steps Involved in the DTF Printing Process

Understanding the DTF printing process is essential for anyone looking to master custom apparel production. The process begins with design creation, where graphic design software is utilized to produce a template tailored for the DTF method. Once the design is ready, it is printed onto a transfer film using specialized DTF inks, which are formulated to ensure vibrant colors and durability. After printing, a powdered adhesive is applied to the wet ink, setting the stage for high-quality transfers.

The final steps in the DTF process involve heat transfer, where the film is applied to the fabric using heat and pressure, allowing the printed design to adhere securely. This method is versatile, allowing for transfers onto various materials, from cotton to synthetic blends. Complete knowledge of each stage, from the initial design to the final heat application, empowers businesses to refine their skills and produce exceptional custom apparel.

Market Trends Driving DTF Printing Adoption

As the custom apparel market continues to evolve, several significant trends are driving the adoption of DTF printing technology. One key trend is the growing demand for personalized products. Consumers today seek unique items that reflect their personal style, and DTF printing allows businesses to offer customizable options without the limitations of traditional printing methods. This shift towards personalization represents a lucrative opportunity for brands employing the DTF approach.

Moreover, the cost-effectiveness of DTF printing appeals to businesses looking to increase profitability while maintaining high-quality output. As traditional methods like screen printing fall out of favor due to cost and setup complexities, DTF has emerged as a favorable alternative. Its ability to handle low-volume orders and offer quick turnaround times perfectly aligns with current consumer expectations, cementing DTF printing’s position as an essential technology in the custom apparel industry.

Graphic Design Tips for DTF Success

Effective graphic design is foundational to the success of any DTF printing project. It’s essential to create designs that not only look good but also translate well onto fabric. Using high-resolution images and ensuring that color contrasts are appropriate are crucial components of effective design. Additionally, understanding the capabilities and limitations of DTF printing will enhance the likelihood of achieving the desired outcome.

Furthermore, employing color separation techniques can help achieve optimal results when transferring designs onto fabrics. Colors that blend seamlessly and avoid excessive detail can significantly improve print quality. Many successful DTF printers invest time in experimenting with various designs and colors to discover what works best for their equipment and offerings, ultimately helping them stand out in the competitive landscape of custom apparel.

Resources to Master DTF Printing Techniques

To excel in DTF printing, leveraging available resources is vital for both novice and experienced printers. Various online platforms provide valuable tutorials on every aspect of the DTF process, from initial setup to troubleshooting common issues. Websites dedicated to printing technology often feature in-depth articles and community discussions that enrich understanding and offer practical advice based on real-world experiences.

Additionally, joining community forums and groups focused on DTF printing can foster collaboration and sharing of best practices. Engaging with others in the industry allows users to gain insights into innovative techniques and learn how to overcome challenges frequently faced in DTF production. By staying informed, printers can continually refine their skills and keep pace with advancements in DTF technology.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it work?

The DTF Gangsheet Builder is a specialized tool designed for creating Direct to Film (DTF) prints efficiently. It simplifies the printing process by allowing users to design, print, and transfer high-quality graphics onto fabrics. The builder utilizes advanced color management and user-friendly interfaces to streamline production, making it ideal for custom apparel.

What are the benefits of using DTF printing technology for custom apparel production?

Using DTF printing technology offers several benefits for custom apparel production, including vibrant color output, durability of prints, and the ability to print on various fabric types. The DTF Gangsheet Builder enhances these advantages by facilitating smaller print runs, reducing waste, and streamlining the overall printing process, making it cost-effective for businesses.

How does the DTF Gangsheet Builder improve the printing process?

The DTF Gangsheet Builder improves the printing process by incorporating features like automatic color management, which ensures accurate colors with less manual input. Additionally, it provides enhanced density adjustments to minimize print errors, resulting in consistently high-quality outputs suitable for custom apparel.

What kind of graphic design software can be used for creating designs with the DTF Gangsheet Builder?

For creating designs with the DTF Gangsheet Builder, you can use various graphic design software tools such as Adobe Illustrator, CorelDRAW, or free alternatives like Inkscape. These tools help prepare templates that can be printed using DTF printing technology, enabling intricate and colorful designs for custom apparel.

Can beginners utilize the DTF Gangsheet Builder effectively?

Yes, beginners can effectively utilize the DTF Gangsheet Builder, as it features a user-friendly interface and accessible tutorials. Online resources, including videos and articles, support novices in mastering the DTF printing process from design to final product, making it an excellent entry point into the world of custom apparel.

What types of fabrics are compatible with DTF printing technology?

DTF printing technology is compatible with a wide range of fabrics, including cotton, polyester, and blended materials. This versatility makes the DTF Gangsheet Builder suitable for various custom apparel applications, allowing businesses to cater to diverse customer preferences and fabric choices.

| Key Points | Details |

|---|---|

| What is DTF Printing? | A method applying ink directly onto a transfer film for high-quality fabric prints. |

| Key Steps in DTF Process | 1. Design Creation 2. Film Printing 3. Powder Application 4. Heat Transfer 5. Finalization |

| Technological Advancements | Automatic color management and error reduction features enhance print quality. |

| Enhanced User Experience | User-friendly interfaces and educational resources make it accessible for beginners and pros alike. |

| Market Trends | Growing acceptance of DTF due to cost-effectiveness and versatility in print runs. |

| Resources and Guides | Video tutorials, blogs, and community forums aid in mastering DTF printing. |

Summary

DTF Gangsheet Builder is a transformative tool in the custom printing landscape, providing users with an efficient way to create and execute high-quality designs. As the demand for personalized apparel grows, mastering this technology is essential for businesses aiming to stand out in the competitive market. With advancements in automation and user experience, DTF printing not only simplifies the creation process but also enhances output quality, making it a preferred choice over traditional methods. By embracing the DTF Gangsheet Builder, you equip yourself with the creative freedom necessary to produce stunning and unique designs tailored to customer needs.