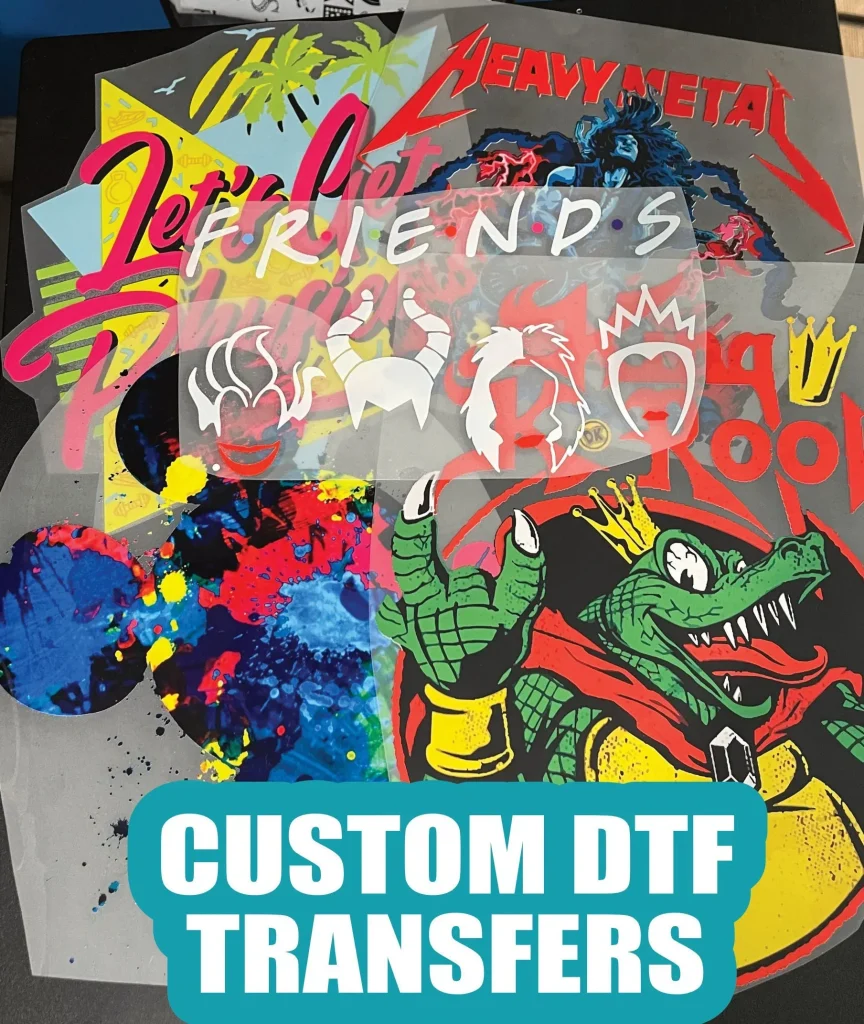

DTF transfers, or Direct-to-Film transfers, are reshaping the landscape of custom apparel design by providing unique and vibrant printing options. This innovative technique allows for high-quality digital transfer printing that is not only visually striking but also eco-friendly, appealing to the growing market of sustainable fashion enthusiasts. With DTF, designers can explore an array of colors and details, making it an ideal choice for intricate textile printing techniques that set their products apart. Moreover, as sustainability becomes an essential aspect of consumer choices, incorporating DTF transfers aligns seamlessly with eco-conscious practices in fashion. Through this blog post, we’ll delve into the exciting world of DTF transfers, offering valuable tips and tricks to elevate your design game while minimizing environmental impact.

Also known as Direct-to-Film printing, DTF technology represents a remarkable advancement in the realm of digital fabric printing. This method utilizes a specialized process that enhances the vibrancy and detail of designs, making it highly sought after in the competitive field of custom clothing creation. As consumers increasingly demand eco-friendly printing solutions, the benefits of using DTF become clear, contributing to a sustainable fashion ethos that resonates with modern buyers. By embracing this versatile approach to textile printing, designers can create unique pieces that capture attention while promoting eco-friendly practices. In this discussion, we will explore how DTF transfers can revolutionize your design strategies and resonate with a broader audience.

The Evolution of DTF Transfers in Custom Apparel

The landscape of custom apparel design has been transformed by Direct-to-Film (DTF) transfers, a modern technology that bridges the gap between creativity and practicality. Historically, traditional printing methods limited designers to certain fabric types and colors, but DTF has dismantled these barriers, allowing for intricate patterns and vivid colors across a wide range of materials. This evolution has enabled designers not only to express their artistic vision but to cater to the diverse preferences of consumers seeking unique, custom apparel.

Moreover, the advancements in DTF technology continue to pave the way for improved production capabilities. With each iteration, designers gain access to enhanced tools and resources, making the creative process smoother and more efficient. As the industry adapts to these innovations, we see an increased appreciation for the sustainable aspects of DTF. As brands prioritize eco-friendly practices, DTF offers a compelling option that aligns with market demands for both stunning designs and responsible manufacturing methods.

Sustainable Fashion Through DTF Technology

Sustainability is no longer just a trend; it’s a necessity in the fashion industry. DTF technology seamlessly integrates into this movement, offering a printing solution that minimizes waste and optimizes resource use. By employing eco-friendly inks and targeting specific fabric needs, DTF transfers reduce the environmental impact associated with traditional printing techniques. As a result, designers can create stunning, eye-catching apparel without compromise, meeting the growing demand for sustainable products.

The commitment to sustainable fashion has turned into a strategic advantage for brands looking to resonate with eco-conscious consumers. By embracing DTF technology, brands can showcase their dedication to the environment while still delivering high-quality, custom designs that reflect their unique style. This dual focus on creativity and responsibility not only helps in building a loyal customer base but also positions brands as leaders in a marketplace that increasingly values sustainability.

Recent advancements in DTF technology further strengthen its position in sustainable fashion. Innovative approaches mean that less material is wasted during the printing process, and with on-demand production capabilities, businesses can reduce overstock and minimize their carbon footprint. This creates a more efficient supply chain that supports both profitability and environmental consciousness.

Innovative Techniques That Enhance DTF Printing

Innovation within the DTF printing arena is fostering new techniques that can elevate the caliber of custom apparel designs. Color knockout techniques represent just one example of how designers can push boundaries in DTF printing. This process allows for striking contrast and multi-layered designs, culminating in a product that stands out in a crowded marketplace. As designers hone these skills, they create unique offerings that captivate audiences looking for something different.

Incorporating cutting-edge digital transfer printing techniques allows designers to play with textures and finishes previously thought challenging. As new materials are introduced and refined, such as environmentally friendly fabrics that pair well with DTF, the potential for innovation expands. This ongoing evolution not only enhances the creative freedom of designers but also empowers them to embrace sustainable practices that are crucial for the future of the fashion industry.

Choosing DTF Over Other Textile Printing Techniques

Selecting the right printing technique for your project is essential. DTF transfers stand out among traditional options like screen printing and sublimation due to their versatile applications on various fabric types. Unlike sublimation, which is primarily limited to polyester fabrics, DTF can be effectively used on cotton and blends, allowing for a broader range of creative opportunities. This versatility enables designers to explore diverse textures and finishes that elevate their artwork beyond traditional capabilities.

Additionally, DTF printing allows for vivid colors and intricate details without sacrificing quality. As designers weigh their options, the flexibly offered by DTF can lead to creative breakthroughs. Whether developing custom apparel for sports teams, promotional gear, or unique fashion pieces, understanding the advantages of DTF compared to other techniques ensures that creators can meet client demands while delivering exceptional quality and design.

Exploring Market Trends in DTF Printing

The DTF printing market is experiencing rapid growth, driven by the increasing demand for custom, on-demand printing solutions. Reports show a rising interest in unique designs and personalized products that resonate with consumers, particularly in regions with expanding markets such as South Africa. This growing consumer base provides vast opportunities for designers and entrepreneurs to thrive within this innovative printing technology.

Moreover, the rise of digital transfer printing is providing new avenues for profitability in the fashion industry. Brands leveraging DTF technology can quickly respond to trends and customer preferences, allowing for faster turnaround times and increased customization capabilities. As the demand for eco-friendly practices and custom apparel continues to rise, DTF printing is positioned to become a cornerstone for businesses aiming to navigate this evolving landscape successfully.

Practical Tips for Mastering DTF Transfer Designs

To truly excel in DTF printing, it’s crucial for designers to become adept at mastering various fabric types and their interaction with the print technology. Testing different textiles can illuminate how different materials respond to DTF processes and how they can influence the final product’s aesthetic and durability. Cotton, polyester blends, and other fabrics each provide unique attributes that can enhance or challenge a design, making exploration a key aspect of the design journey.

Furthermore, focusing on color knockout and layering techniques can drastically increase the complexity and visual appeal of designs. By understanding the principles of color compatibility and layering in DTF printing, artists can create captivating garments that catch the eye and communicate their brand’s message effectively. These practical considerations not only refine a designer’s skills but also enhance the overall quality of the product, ensuring that each piece produced stands out in an increasingly competitive market.

Frequently Asked Questions

What are DTF transfers and how do they work in custom apparel design?

DTF transfers, or Direct-to-Film transfers, are a printing method that allows designers to apply high-quality, vibrant designs onto various fabrics. The process involves printing designs onto a special film using eco-friendly inks, which are then heat transferred onto the apparel, promoting detail and durability. This technique is ideal for custom apparel design as it provides flexibility in materials and allows for unlimited color options.

How do DTF transfers compare to other textile printing techniques?

Unlike techniques like sublimation, which only work on polyester, DTF transfers can be applied to a wide range of fabrics including cotton and blends. This versatility expands creative possibilities for designers, enabling them to work with various textiles without compromising on quality or vibrancy. Understanding these differences is key to choosing the right printing method for your projects.

What are the sustainability benefits of using DTF transfers in fashion?

DTF transfers contribute to sustainable fashion by minimizing waste and using eco-friendly inks. The unique application process generates less excess material compared to traditional printing, appealing to environmentally conscious consumers. As sustainability becomes increasingly crucial, employing DTF technology can enhance your brand’s reputation and support a more responsible apparel industry.

Can you achieve detailed designs with DTF transfers?

Yes, DTF transfers are known for their ability to produce intricate and detailed designs that stand out. Thanks to advanced printing technology, designers can utilize unlimited colors and intricate details without losing vibrancy. This makes DTF an excellent choice for creating stunning custom apparel that attracts attention.

What recent innovations are impacting DTF transfer technology?

Recent innovations in DTF transfer technology, such as advancements showcased at events like the DTF Expo, are enhancing the capabilities of this printing method. These innovations allow for faster production times, greater intricacy in designs, and improved heat transfer techniques, keeping designers at the forefront of the custom apparel market.

What practical tips can help improve my DTF transfer designs?

To improve your DTF transfer designs, experiment with color knockout techniques to enhance complexity and vibrancy. Test various fabric types to discover unique textures and finishes, and always consider sustainability by using eco-friendly materials. By following these practices, you can create stunning, impactful designs that resonate with eco-conscious consumers.

| Key Point | Details |

|---|---|

| Understanding DTF Technology | DTF printing allows for unlimited colors and intricate details, producing high-quality designs efficiently while minimizing waste. |

| Sustainability Benefits | DTF reduces waste compared to traditional printing methods, making it an eco-friendly choice that appeals to environmentally conscious consumers. |

| Recent Innovations | New technologies and advancements in DTF printing enhance its capabilities, allowing for faster production times and more intricate designs. |

| Choosing Between DTF and Other Techniques | DTF can be applied to various materials unlike sublimation, giving designers more options to work with different fabrics. |

| Market Growth and Opportunities | The DTF printing market is expanding rapidly, driven by demand for unique, on-demand printing solutions. |

| Practical Tips for DTF Designs | Experiment with color knockout techniques, test different fabrics, and emphasize sustainability to enhance your designs. |

Summary

DTF transfers are a revolutionary method for creating stunning designs in the custom apparel industry. With their ability to produce vibrant and detailed finishes on various fabric types, DTF transfers not only enhance the aesthetic of garments but also align with sustainability practices, minimizing waste. As the technology evolves, staying updated with the latest innovations can unlock new creative avenues. By employing practical techniques and embracing the environmentally friendly aspects of DTF transfers, designers can create unique, eye-catching products that appeal to a modern audience. This approach not only sets designs apart but also contributes to a thriving market, presenting numerous opportunities for growth and creativity.