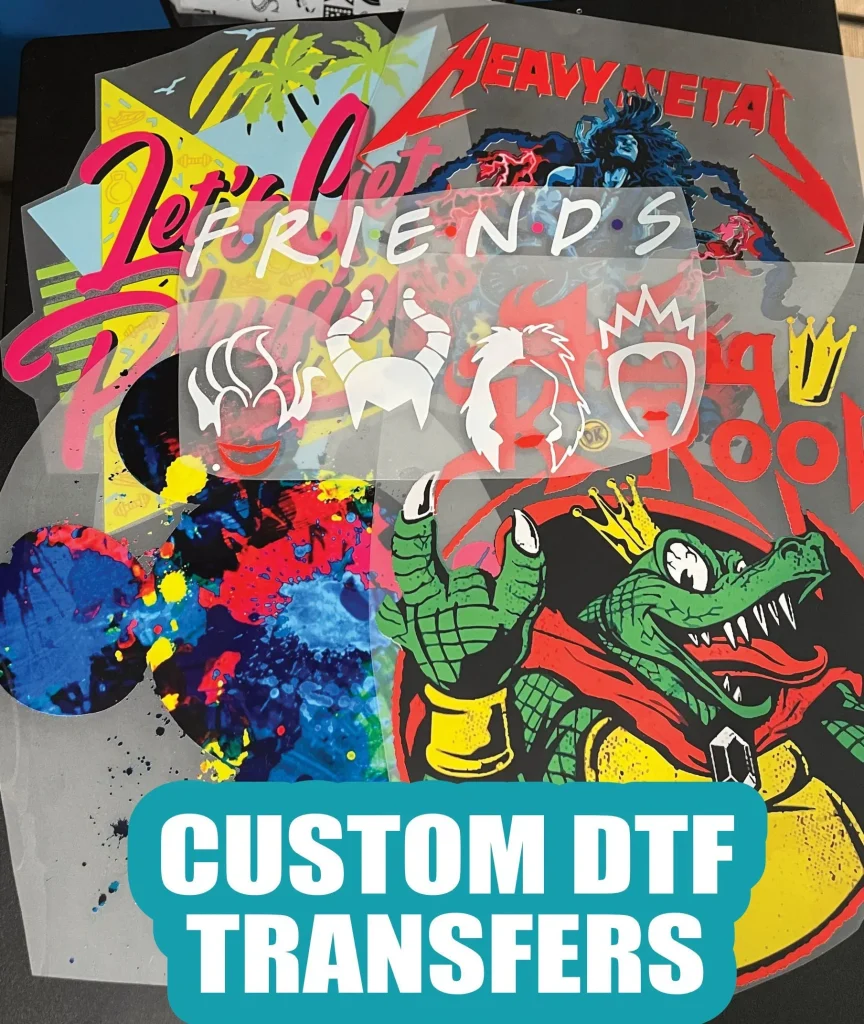

DTF transfers, or Direct-to-Film printing, are revolutionizing the world of graphic design and fabric customization. This innovative printing technique allows artists and professionals alike to produce vibrant, high-quality designs that stick beautifully to various types of textiles, from cotton to polyester. By applying DTF design techniques, creators can achieve incredibly detailed prints with a simple heat press application, making the process both efficient and effective. With the addition of adhesive powder for DTF, the results are not only visually stunning but also durable—perfect for fashion items, promotional materials, and beyond. Dive into the exciting realm of DTF transfers, where your design ideas come to life with unparalleled clarity and color!

Embracing the art of transferring designs directly onto films offers a unique opportunity for enthusiasts and professionals in the customization industry. Known as Direct-to-Film printing, this modern technique has quickly gained traction for its ability to create intricate graphics and ensure long-lasting designs. By harnessing the power of a heat press, individuals can transfer their artwork seamlessly onto diverse fabric types, while the use of specialized adhesive powder guarantees a strong bond. This process serves not just hobbyists creating eclectic apparel but also businesses looking to enhance their offerings in the competitive graphic design landscape. Discover how this innovative printing method can transform your crafting experience and elevate your creative projects to new heights!

The Advantages of DTF Transfers in Custom Apparel

DTF transfers offer a unique blend of quality and versatility, making them an excellent choice for custom apparel creation. Unlike traditional screen printing, DTF allows for more intricate designs with vibrant colors that do not fade easily over time. This method is particularly advantageous for small batch runs, as it eliminates the need for using multiple screens and inks, reducing setup time and costs. Additionally, DTF works effectively on a variety of fabrics, including cotton, polyester, and blends, which expands the range of custom apparel options available.

Moreover, DTF transfers are perfect for capturing detailed images and gradients. Since the designs are printed on a special film, they can reproduce photographic quality that can cater to personal expressions or brand identities. This capability allows designers to explore their creativity without limiting themselves to simple graphics, thus enhancing the appeal of customized clothing in today’s fashion landscape.

Essential Tools for DTF Transfer Printing

To begin your journey into DTF transfer printing, obtaining the right tools and materials is crucial. First and foremost, you’ll need a DTF printer or an inkjet printer compatible with DTF inks. This printer will allow you to produce high-resolution designs suitable for film printing. Equally important are the DTF film sheets that are specially coated to receive the ink without leaving a residue or blurring the details of the design.

Another vital component of DTF transfers is the adhesive powder, which plays a significant role in ensuring your designs adhere well to fabric. This powder gets melted into the printed design during the heat application process, creating a strong bond that withstands washing and wearing. Lastly, a reliable heat press is essential. It provides a consistent temperature and pressure, which is important for the successful transfer of designs, ensuring that your final product is durable and looks great.

Step-by-Step Process of DTF Printing

Creating stunning designs using DTF transfers involves a systematic step-by-step process that professional and amateur creators alike can follow. The initial stage is designing your artwork using graphic design software like Adobe Illustrator. It’s recommended to set your document at a high resolution of 300 DPI to maintain print quality. Opt for colors and styles that complement your chosen fabric, as this will significantly affect the final outcome.

Next comes the printing phase, where you’ll load the DTF film into your printer, ensuring the correct printer settings are applied. Following this, allow the ink to dry completely before applying adhesive powder on the wet design. This step is crucial, as an even coat of powder will ensure that your artwork adheres perfectly during the heat transfer. Following these steps meticulously will lead to the successful transfer of your vibrant design onto fabric.

Best Practices for DTF Transfer Success

Implementing best practices is key to achieving quality results with DTF transfers. One important tip is to always test your designs on sample fabrics before proceeding with bulk printing. This practice not only allows you to evaluate how the colors and details of your design translate onto different materials, but it also helps you identify any necessary adjustments needed for optimal printing outcomes.

Additionally, always use a heat press instead of an iron for transferring your designs. Heat presses provide even heat distribution and consistent pressure, which are crucial for a successful transfer that lasts. Strategic spacing of designs on your DTF film is also essential. By maximizing space and minimizing waste, you can reduce costs and increase profitability, which is particularly beneficial for businesses looking to scale.

Emerging Trends in DTF Printing

The realm of DTF printing is rapidly evolving, with emerging trends shaping how designers create and consumers engage with custom apparel. One of the most significant trends currently making waves is the use of eco-friendly DTF inks. As more consumers demand sustainable fashion options, printers are adopting chemical-free inks that not only reduce environmental impact but also allow for a wider range of creative expressions.

Moreover, advancements in DTF design techniques are pushing the boundaries of what can be achieved with this technology. Innovative transfer films and improved adhesive powder formulations are enhancing the durability and flexibility of transfers, ensuring that designs stand the test of time. As these trends continue to develop, those in the custom apparel industry must stay informed and adapt their strategies to leverage these innovations effectively.

Conclusion: Unleash Your Creativity with DTF Transfers

In conclusion, DTF transfers represent a remarkable technique for anyone looking to create stunning and long-lasting designs. By understanding the core elements of the DTF process—from the essential tools needed to the detailed step-by-step method—creators can elevate their craft and uncover new levels of potential in custom apparel production. Whether for personal projects or small business ventures, DTF printing can provide the quality and adaptability needed in today’s dynamic market.

With the right preparation and adherence to best practices, you can experience the satisfaction of seeing your unique designs come to life. Dive into the world of DTF printing today and embrace the opportunity to express your individuality through beautifully crafted clothing, whether for personal wear or to share with customers.

Frequently Asked Questions

What are DTF transfers in textile printing?

DTF transfers, or Direct-to-Film transfers, are a modern printing technology that involves printing designs onto a specialized film, applying adhesive powder, and then transferring it onto fabrics using a heat press. This method allows for vibrant colors and intricate designs on various materials.

How do I apply adhesive powder for DTF printing?

To apply adhesive powder for DTF printing, first, make sure the ink on the printed film is still hot. Generously sprinkle the adhesive powder over the wet ink to ensure an even coat. After that, use heat to melt the adhesive onto the design for a strong bond.

What kind of heat press is best for DTF transfers?

A clamshell or swing-away heat press is ideal for DTF transfers, as it allows for consistent pressure and temperature. Ensure that the heat press can reach approximately 320°F (160°C) for optimal transfer results and use a Teflon sheet to protect the design during the process.

Can I use any printer for DTF design techniques?

Not all printers are suitable for DTF design techniques. You will need a DTF printer or an inkjet printer compatible with DTF inks. Ensure that your printer is set to the correct specifications for the DTF film you are using.

What should I consider when choosing fabrics for DTF printing?

When selecting fabrics for DTF printing, consider their compatibility with the DTF process. Natural fibers like cotton and polyester blends work well. Always perform a test print on sample fabrics to understand how the material interacts with DTF transfers to avoid production issues.

What are some recent trends in DTF printing?

Recent trends in DTF printing include the rise of eco-friendly DTF inks that have no harmful chemicals, catering to the growing consumer demand for sustainable fashion. Additionally, more businesses are exploring creative and personalized applications for DTF transfers, expanding customization opportunities.

| Key Point | Description |

|---|---|

| Understanding DTF Transfers | DTF transfer printing produces high-quality, vibrant prints on various fabrics, offering detailed designs and stunning colors. |

| Tools and Materials Needed | Printers (DTF or inkjet), DTF film sheets, adhesive powder, heat press, design software (e.g., Adobe Illustrator). |

| Step 1: Design Creation | Create high-resolution artwork (300 DPI) suitable for your fabric choice. |

| Step 2: Printing | Print the design on DTF film, ensuring full ink drying before next steps. |

| Step 3: Applying Adhesive | Sprinkle adhesive powder on wet ink and melt it to bond design. |

| Step 4: Transfer to Fabric | Position film on fabric, cover with Teflon, and press at 320°F (160°C) for 15 seconds. |

| Step 5: Peeling and Finishing | Allow to cool, then peel film to reveal vibrant design. |

| Best Practices | Test on sample fabrics, use a heat press, and optimize design spacing. |

| Recent Trends in DTF Printing | Rise of eco-friendly inks, catering to sustainable fashion. |

Summary

DTF Transfers have become an essential technique for artists and businesses eager to create stunning, vibrant designs on various textiles. This method not only provides exceptional color fidelity and detail but also allows for great versatility across different materials, making it an attractive option for both personal projects and commercial applications. With a straightforward process that includes design creation, printing, and heat transfer, anyone can achieve professional-looking results. Additionally, the increasing popularity of eco-friendly inks aligns with modern consumer trends, presenting opportunities for environmentally conscious businesses. Embrace the potential of DTF Transfers and elevate your crafting or business projects to new heights.