If you’re passionate about crafting and looking to elevate your creations, DTF transfers, or Direct-to-Film transfers, could be the perfect solution for you. This innovative printing technique offers crafters the ability to transfer high-quality images onto a variety of fabrics, ensuring vibrant results that stand the test of time. Our in-depth DTF printing guide will walk you through the impressive capabilities of this method, including the essential craft printing techniques that can unlock your artistic potential. As we explore the world of DTF designs, you’ll discover how easy it is to achieve professional-quality fabric transfers right from your home. Join us as we dive into the step-by-step process of creating stunning designs with DTF transfers!

For those exploring cutting-edge crafting methods, direct-to-film transfers represent a transformative approach to fabric printing. This modern technique allows you to imprint detailed, vivid designs directly onto textile surfaces, making it an increasingly popular choice among artisans and small business owners alike. Instead of traditional printing methods, which can be limiting, DTF offers flexibility and high-quality results suitable for various projects. Craft enthusiasts can harness the power of DTF printing by learning effective strategies to apply this technique in their work. As you embark on your journey with DTF transfers, prepare to expand your creative horizons and achieve extraordinary fabric designs.

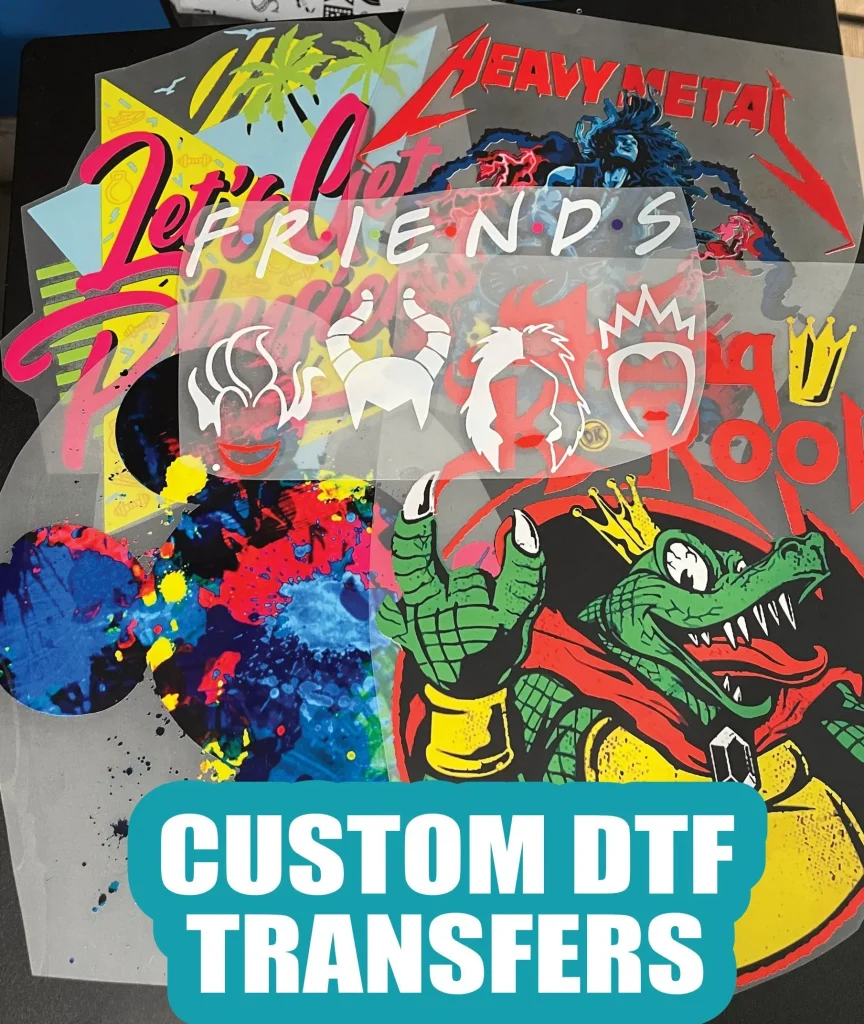

Exploring the Benefits of DTF Transfers for Crafters

DTF transfers offer an array of advantages for crafters eager to enhance their fabric printing skills. One primary benefit is the ability to print high-quality designs onto a variety of fabric materials, creating vibrant and detailed images that can withstand wear and tear. DTF printing also eliminates the need for complex setups required by traditional printing methods, making it accessible for hobbyists and small businesses alike. Many users appreciate the versatility of DTF, as it allows for customization on different fabrics, from cotton to polyester, ensuring that any project can achieve the desired look.

Furthermore, DTF transfers simplify the process of creating custom apparel. Unlike screen printing, which often involves multiple screens and setups, DTF allows for seamless printing of intricate designs with ease. The meticulous detail and color gradients achievable through DTF technology cater to modern design needs, such as gradient fills and detailed logos. Consequently, crafters can experiment with unique inventory ideas, helping them stand out in a competitive market by offering exceptionally detailed and personalized products.

A Comprehensive DTF Printing Guide for Beginners

If you’re new to DTF printing, following a comprehensive guide is key to achieving successful results. Start by investing in the right tools, including a DTF printer, DTF transfer films, and a heat press. These pieces of equipment are essential for ensuring that your designs are transferred properly onto fabrics. Familiarize yourself with the specific settings and materials recommended for your particular brand of DTF printer, as each unit may require different configurations for optimum results.

Next, understanding the design process is crucial. High-resolution images and proper color management must be prioritized, as they will significantly impact print quality. Make sure to configure your designs accurately in graphic software. It’s helpful to create a few practice prints before moving onto larger runs, allowing you to troubleshoot any issues with alignment or design clarity. This step-by-step familiarity can boost your confidence and ensure that your first attempts yield impressive results.

Essential Tips for Creating High-Quality Fabric Transfers

Creating high-quality fabric transfers using DTF involves attention to detail in both design creation and application. One essential tip is to ensure your images are designed at a resolution of at least 300 DPI. This will help maintain clarity and vibrancy in your final prints. Additionally, it is advisable to utilize color profiles that match your printer’s calibration settings to avoid any discrepancies in color output.

Another key factor is the use of proper adhesive and curing methods. After applying the adhesive powder to your printed design, ensure it is thoroughly cured before transferring it to fabric. This curing process is critical as it determines how well the design will adhere during the heat transfer. Experimenting with heat press settings, such as temperature and time, is also vital, as every fabric behaves differently under heat. Achieving precision with these elements will ultimately lead to stunning, long-lasting designs.

Innovations Reshaping the DTF Printing Landscape

The DTF printing landscape continues to evolve with innovations that are reshaping the way crafters approach their projects. For instance, the introduction of gang sheets allows multiple designs to be printed simultaneously, significantly saving time and resources, especially for businesses looking to scale their offerings. This method means that crafters can maximize their print runs to produce a variety of products while reducing material waste, effectively optimizing their workflow.

Moreover, technological advancements in DTF printing equipment have made it easier for new users to enter the market. Compact and affordable printers suitable for home use, such as those released by various manufacturers, have made DTF printing more accessible. This democratization of technology means that anyone can experiment with fabric transfers, leading to a surge in creativity and innovation within the crafting community. As a result, a wider array of products and unique designs are surfacing in the market.

Mastering Craft Printing Techniques with DTF Transfers

Mastering craft printing techniques using DTF transfers opens new avenues for creativity. DTF printing enables crafters to experiment with different fabric types, textures, and colors, allowing for an extensive range of personalized items. Whether you are designing shirts, tote bags, or home decor, the DTF method provides the flexibility needed for unique projects. To enhance your technique, continuously practice and explore various design software programs to refine your skills.

Additionally, reviewing the latest trends in craft printing can inspire fresh ideas. Incorporate elements such as layering designs or utilizing mixed media to create standout pieces that reflect current aesthetics. Engage with online communities of other crafters to share tips and tricks, as well as gather feedback. Embracing collaboration can also enhance your technique, allowing you to learn from others’ experiences and push the boundaries of your DTF creations.

Tips for Designing Eye-Catching DTF Designs

When it comes to creating eye-catching DTF designs, it’s essential to focus on elements that will grab attention. Consider using bold colors, contrasting elements, and dynamic compositions that can be effectively translated onto fabric. Incorporating unique typography, playful layouts, and crisp images can elevate your designs and make them more marketable. Tools like Adobe Illustrator offer features that can help refine your visual concepts, ensuring they will translate effectively in the printing process.

It’s also beneficial to stay updated on design trends influencing the DTF printing industry. Incorporating seasonal themes, popular culture references, or social media trends into your designs can help attract a modern audience. Pay attention to works by prominent designers or trending themes on platforms like Instagram and Pinterest for inspiration. By ensuring your designs are not only unique but also relevant, you can increase engagement with potential customers and create a more significant impact in the market.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, are a revolutionary craft printing technique where designs are printed directly onto a special film and then transferred onto fabric using heat and pressure. This method creates high-quality fabric transfers that are vibrant and durable, making it a popular choice for crafters and small businesses.

What materials do I need for DTF printing?

To start with DTF printing, you will need a DTF printer, DTF transfer film, powder adhesive, and a heat press. These essential tools enable you to create stunning designs that are easily transferred onto a variety of fabrics, enhancing your crafting projects.

Can I create multiple designs on one DTF transfer film?

Yes, using gang sheets is a popular method in DTF printing that allows for multiple designs to be printed on a single transfer film. This technique saves time and improves workflow efficiency, making it ideal for businesses and crafters looking to produce several DTF designs in one go.

What settings should I use for my DTF printer?

When using a DTF printer, it’s crucial to select the right print settings. This typically includes mirroring your design before printing, selecting high-resolution output (300 DPI or higher), and following specific guidelines provided by your printer’s manufacturer to achieve the best results in your DTF transfers.

How do I ensure that my DTF transfers adhere properly to fabric?

To ensure that DTF transfers adhere well to fabric, it’s important to apply a powder adhesive after printing your design on the film. The adhesive should be sprinkled onto the wet ink, cured through heat pressing, and the transfer needs to be applied under the recommended temperature and pressure during the heat transfer process.

What types of fabric can be used with DTF transfers?

DTF transfers are versatile and can be used on a variety of fabric types, including cotton, polyester, and blended fabrics. The durability and vibrancy of DTF designs make them suitable for a wide range of applications, from apparel to custom fabric projects.

| Step | Description |

|---|---|

| 1: Design Creation | Create vibrant designs using software like Adobe Illustrator, ensuring images are at least 300 DPI. |

| 2: Printing Your Design | Print the design onto DTF transfer film, ensuring to mirror the design and use the correct printer settings. |

| 3: Prepare the Transfer | Apply powder adhesive to the wet ink on the printed design, cure it with heat press for about 10 seconds. |

| 4: Heat Transfer Process | Preheat the heat press, position the fabric, apply the transfer and press for about 10-15 seconds before cooling and peeling. |

Summary

DTF transfers are revolutionizing the world of fabric printing, offering crafters and businesses a remarkable method to create detailed, high-quality designs. This practical guide illustrates the essential steps for using DTF transfers effectively, from designing vibrant graphics to executing the heat transfer process. With advancements in printing technology and resources such as gang sheets and accessible DTF printers, the artistry possibilities are boundless. Engaging in DTF transfers provides an exciting avenue for both seasoned creators and newcomers to elevate their crafting. By harnessing the outlined techniques, anyone can produce eye-catching, custom designs that leave a lasting impact.