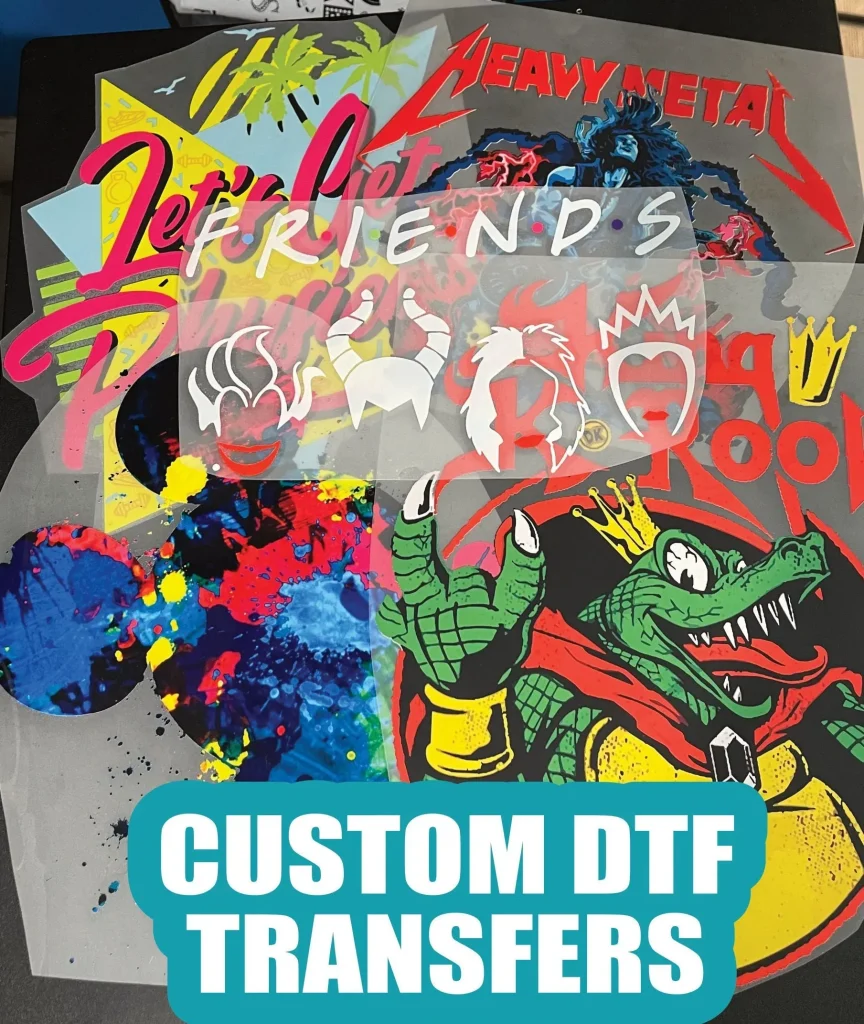

DTF transfers have emerged as a game-changing innovation in the domain of textile prints, delivering bold colors and remarkable versatility. This cutting-edge technique uses Direct-to-Film (DTF) printing, which is perfect for a variety of fabrics, making it an ideal choice for both entrepreneurs and DIY enthusiasts alike. In this guide, we will meticulously explore the DTF transfer process from start to finish, ensuring that you have all the DTF printing instructions necessary to succeed. By understanding the intricacies involved in fabric transfers, you can consistently achieve high-quality results that last. Join us on this journey to master the art of DTF transfers, transforming your designs into stunning wearable art!

When it comes to fabric imprinting, the direct-to-film method stands out as a revolutionary technique that dramatically enhances creativity and efficiency. Known as DTF printing, this approach utilizes a specialized film to seamlessly transfer designs onto various textile surfaces. Whether applied to t-shirts, tote bags, or any custom fabric project, the DTF transfer process ensures that intricate details and vibrant colors are preserved throughout. This comprehensive guide will provide you with the necessary DTF printing instructions and tips for achieving flawless results. Explore the possibilities of fabric transfers and elevate your crafting skills with this dynamic printing method!

Understanding the Basics of DTF Printing

Direct-to-Film (DTF) printing is an innovative technique that has drastically transformed how textile graphics are produced. This method allows for stunningly vibrant designs that can be applied to a variety of fabric types, from cotton to polyester. One of the most appealing aspects of DTF is its ability to achieve photorealistic images with intricate details that simply cannot be matched by traditional methods such as screen printing. Furthermore, DTF printing offers a more efficient workflow for businesses, reducing the setup time and costs required for each job.

When exploring the world of DTF printing, it’s essential to understand the underlying mechanics of the process. Designs are first printed onto a special film, coated with a unique adhesive powder. This film is then used to transfer the design onto the fabric using heat and pressure, resulting in long-lasting and colorful prints. The adaptability of the DTF printing method makes it an excellent choice for anyone looking to produce custom apparel, promotional items, or decorative textiles.

The Importance of Quality DTF Films

Choosing high-quality DTF films is paramount to achieving successful transfers. The right film ensures that the ink adheres correctly and allows for precise detailing without smudging. Inferior films may result in poor adhesion, leading to fading prints or designs peeling off after washing. It’s advisable to source DTF films from reputable suppliers who specialize in the printing industry, as they often provide reliable products that guarantee better performance.

In addition to quality, the type of DTF film can vary for different fabrics. You may encounter films that are intended for specific types of textiles, like light or dark garments, which could significantly affect your final results. Therefore, understanding the characteristics of the films you choose will have a direct impact on the quality of your fabric transfers.

Essential DTF Printing Instructions

Mastering the DTF transfer process begins with understanding the essential printing instructions. The initial step involves preparing your artwork using suitable graphic design software. Programs like Adobe Illustrator or CorelDRAW are ideal for creating detailed and high-resolution designs. It’s crucial to save your finalized artwork in formats that maintain quality, such as PNG, which supports transparent backgrounds and vibrant colors.

Following this, the setup of your printer plays a central role in achieving ideal results. Ensuring your printer is properly configured to accommodate DTF printing specifications, such as using pigment inks, will produce vibrant prints that stand the test of time. Pay careful attention to the print settings, particularly to mirror the image before printing, essential for designs that include text.

The DTF Transfer Process Explained

The DTF transfer process encompasses multiple critical steps, all of which contribute to the overall quality of your final product. After printing your design on the DTF film, the next significant phase is the application of adhesive powder. Sprinkling the DTF adhesive evenly over the wet ink is vital; any uneven application could lead to poor adhesion later on. This step cannot be overlooked, as it directly impacts how well the design adheres to the fabric and how durable the final print will be.

Once adhesive is applied, curing it under a heat press is necessary to ensure that it binds effectively with the ink. This step is about precision; applying heat at the correct temperature and for the right duration is paramount to achieving a strong bond. Neglecting this crucial step can lead to a weakened transfer that won’t survive the rigors of washing and wearing.

Tips for Successful DTF Transfer

Everyone can improve their DTF printing skills with practice and patience. A great tip for beginners is to experiment with fabric scraps before applying designs to final products. This approach allows you to fine-tune the DTF process, helping you to understand how different fabrics react to the transfers. Additionally, testing various time and temperature settings is essential, as different fabric types may require adjustments for optimal results.

Moreover, consistent quality control is key for anyone serious about DTF printing. This involves not only maintaining your equipment, such as printers, but also regularly checking the quality of your ink and film supplies. Keeping an eye on these elements will help you avoid common pitfalls and ensure a seamless DTF transfer process.

Recent Innovations in DTF Printing Technology

The landscape of DTF printing is continually evolving, with recent innovations pushing the boundaries of what’s possible within textile graphics. Advancements in ink formulations and film compositions have led to prints that are not only more vibrantly colored but also more durable against wear and tear. Brands are working diligently to develop inks that enhance bonding properties while being eco-friendly, appealing to a broader audience concerned about the environmental impact of printing processes.

Furthermore, ongoing research and development in the field present exciting opportunities for customization and personalization in DTF printing. With tools and resources becoming increasingly accessible, hobbyists and business owners alike can experiment with new techniques and styles, expanding the possibilities of what’s achievable with DTF transfers.

Frequently Asked Questions

What is the DTF transfer process and how does it work?

The DTF transfer process involves printing designs onto a special transfer film, which is then adhered to fabric using a heat press. This method allows for vibrant, long-lasting prints on various fabric types, making it a popular choice for intricate designs.

How do I prepare my design for DTF printing?

To prepare your design for DTF printing, use graphic design software like Adobe Illustrator or CorelDRAW. Save your artwork in PNG format to maintain transparency and ensure that the colors appear vibrant in the final DTF transfers.

What type of adhesive is used with DTF transfers, and why is it important?

DTF transfers use a specific adhesive powder that must be applied to the wet ink immediately after printing. This adhesive is crucial as it ensures proper adherence of the print to the fabric, helping prevent peeling or fading after washing.

What are the common mistakes to avoid in the DTF printing process?

Common mistakes in DTF printing include not mirroring the design before printing, using poor-quality DTF film, and incorrect heat press settings. Each of these missteps can lead to unsatisfactory results, so attention to detail is vital.

Can DTF transfers be applied to any type of fabric?

Yes, DTF transfers can be applied to a wide variety of fabrics, including cotton, polyester, and blends. However, temperature and pressing time may need to be adjusted according to the fabric type for the best results.

What are some tips for achieving perfect results with DTF printing?

To achieve perfect DTF transfers, practice on scrap fabric first, ensure your printer settings are correctly configured, and maintain proper temperature and time adjustments. Consistently check adhesive application to ensure an even and strong bond.

| Key Component | Details |

|---|---|

| DTF Transfers Overview | DTF printing allows designs to be transferred onto fabric using special film, ensuring vibrant colors and fine details. |

| Step 1: Design Preparation | Utilize software like Adobe Illustrator or CorelDRAW; save designs in PNG format to maintain transparency. |

| Step 2: Film Selection | Choose high-quality DTF film to ensure durability and adherence of the print. |

| Step 3: Printing Process | Set up printer with pigment inks; ensure images are mirrored before printing for correct transfer. |

| Step 4: Applying Adhesive | Sprinkle adhesive powder on wet ink; cure using a heat press for strong adhesion. |

| Step 5: Transfer to Fabric | Set heat press to 320°F; press film onto fabric, then peel backing after cooling. |

| Step 6: Final Curing | Press fabric again briefly to ensure bond and durability of the design. |

Summary

DTF Transfers represent an innovative leap in fabric design technology, offering vibrant, durable prints that cater to a range of textile applications. By mastering the intricacies of the DTF transfer process outlined in this guide, you can unlock a world of creative possibilities in your printing ventures. From initial design preparation to the final curing, every step is crucial for achieving the desired results. Remember, continuous practice and adjustment to your techniques will lead to quality improvements. Embrace the dynamic tool of DTF Transfers in your workflow, and watch your designs come to life with unmatched clarity and brilliance!