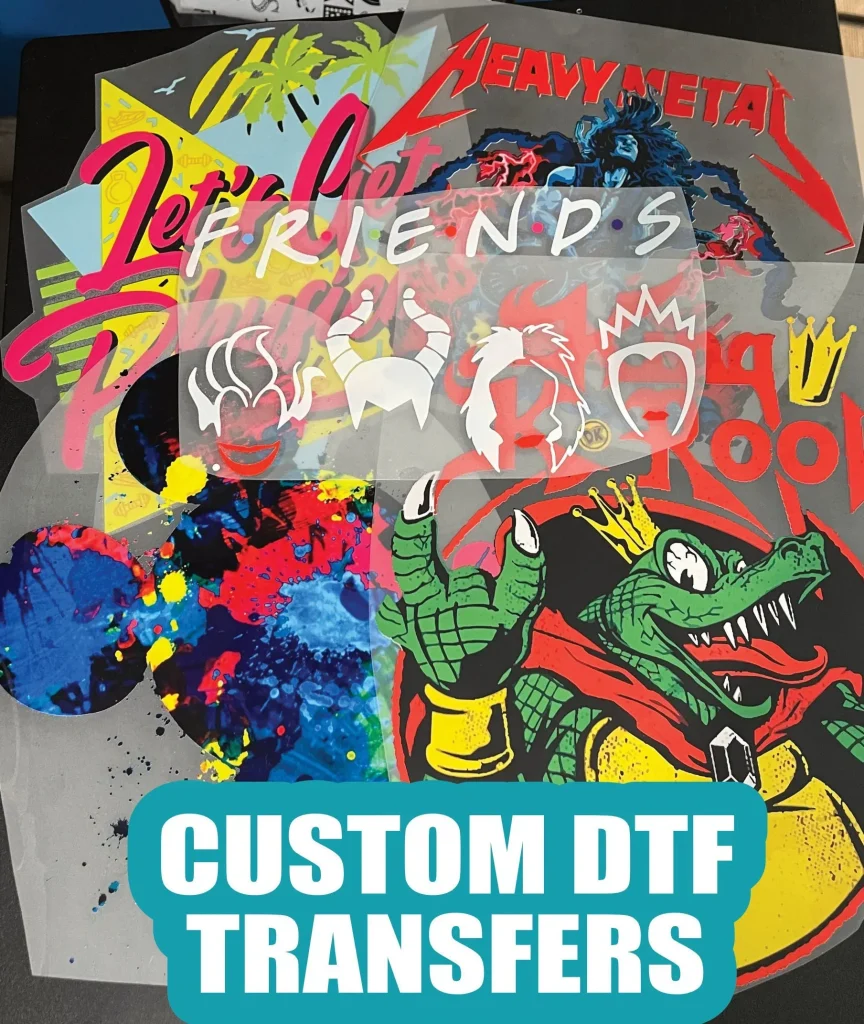

DTF transfers, or Direct to Film printing, represent a transformative innovation in the realm of custom apparel printing. As this cutting-edge print technology gains traction among businesses and entrepreneurs, it promises not only vibrant designs but also efficiency in production. By harnessing fabric transfer techniques that simplify the printing process, DTF heat transfer offers a unique solution for those looking to create high-quality apparel with intricate designs. This technique eliminates the complexity of traditional printing methods, making it a popular choice for both small-scale creators and large companies alike. Dive into the world of DTF transfers to discover how these advancements can elevate your custom printing endeavors.

In the landscape of modern textile printing, Direct to Film (DTF) applications have become a buzzword, leading a new wave of customization possibilities. This innovative approach to fabric transfers has redefined the way designs are created and printed, allowing for seamless integration of imagery on various materials. Often celebrated for its efficiency and color vibrancy, DTF technology has emerged as a frontrunner in the custom apparel sector, rivaling conventional print techniques. By utilizing advanced print technology, professionals can achieve intricate designs that cater to the diverse needs of today’s consumers. As the demand for personalized apparel continues to grow, understanding the fundamentals of DTF alternatives is essential for anyone in the industry.

Understanding Direct to Film Printing Techniques

Direct to Film (DTF) printing has transformed the way custom apparel is produced, offering several advantages that traditional methods cannot match. This technique allows for the application of designs directly onto a specially coated film, which can then be transferred to various fabric types using a heat press. The ability to print multiple colors in a single pass means that designs can be intricate and detailed without the setup costs associated with screen printing.

The DTF printing process begins with a digital design, which is printed using specialized DTF inks that are designed for compatibility with both the film and the target fabric. This technology not only enhances the quality of the prints but also streamlines production, enabling faster turnaround times for custom orders. As a result, businesses can respond more quickly to market demands while maintaining exceptional print quality.

The Power of DTF Heat Transfer

DTF heat transfer processes highlight the versatility of this printing technique. Unlike traditional heat transfer methods, which often require separate layers for each color, DTF simplifies the procedure by allowing all colors to be printed in a single operation. This efficiency not only reduces the time spent in production but also leads to significant cost savings for both small and large scale operations.

Furthermore, the adhesive powder used in DTF transfers enhances the bond between the ink and the fabric. Once heat is applied, the adhesive cures and forms a strong connection with the garment, which improves durability and prevents peeling or fading over time. This feature makes DTF heat transfer an ideal solution for custom apparel that needs to withstand repeated washing without losing its vibrant look.

Innovations in Printable Fabric Technologies

Fabric transfer techniques have evolved significantly, with DTF printing at the forefront of these innovations. Contemporary DTF processes utilize advanced ink formulations that are not only durable but also environmentally friendly. As the printing industry increasingly focuses on sustainability, these innovations meet consumer demand for eco-conscious products, further bolstering the appeal of DTF transfers.

Additionally, advancements in curing processes contribute to improved production efficiency. Modern curing techniques can reduce the amount of time required for each transfer while ensuring a robust adhesion and final product quality. This means that businesses can produce more garments in less time and remain competitive in a fast-paced market, all of which underline the importance of innovations in printable fabric technologies.

Market Trends in Custom Apparel Printing

The custom apparel printing market has seen a significant shift towards digital solutions like DTF transfers, driven by the demand for high-quality products that are quick to produce. As more companies realize the advantages of DTF, the market for this printing method is rapidly expanding, with emerging players offering specialized DTF services to cater to a wide range of clients, from small local businesses to large distributors.

This growth in the market reflects consumers’ preferences for unique, personalized items that showcase their individual styles. As a result, the ability to quickly produce custom apparel at competitive prices makes DTF a preferred choice for businesses looking to capitalize on this trend, further solidifying its place in the future of custom apparel printing.

Benefits of Choosing DTF Transfers for Custom Apparel

Choosing DTF transfers for custom apparel brings numerous advantages, particularly in terms of versatility. Unlike traditional methods that may limit the types of fabrics used, DTF transfers can be effectively applied to a wide array of materials, including blends of cotton, polyester, and more. This flexibility allows businesses to expand their product offerings while catering to diverse customer preferences.

Additionally, the quality of prints produced through DTF technology is remarkable, providing vibrant colors and fine details that hold up to wear. Customers are often impressed by the longevity and resilience of the prints, which remain intact even after multiple washes. This durability not only enhances customer satisfaction but also builds loyalty, making DTF transfers an attractive option for businesses focused on quality.

The Future of DTF Transfer Technology

As technology continues to evolve, the future of DTF transfers looks promising, with continued innovations on the horizon. Manufacturers are investing in research and development to create faster printing and curing processes, which will further streamline production and enhance product quality. These advancements are set to reshape the landscape of custom apparel printing, positioning DTF as a key player in the market.

Moreover, the integration of digital technologies, such as real-time color management software and online design tools, will enable businesses to offer even more customized solutions to their clients. By harnessing these advancements, companies can improve their operational efficiencies while delivering superior products that meet the growing consumer demand for personalization and quality in the realm of custom apparel.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct to Film transfers, involve printing designs onto a special film that is then heat pressed onto fabrics. This process allows for all colors to be printed in a single step, making it efficient for both small and large orders.

What is the main difference between DTF heat transfer and traditional screen printing?

The main difference lies in the printing method. DTF heat transfers use one-step printing for all colors on a film, while traditional screen printing requires multiple setups for each color, resulting in more time-consuming processes.

How do the inks used in DTF transfers ensure print durability?

High-quality DTF inks are specially formulated for excellent adhesion to both the film and the fabric. This ensures vibrant colors that remain durable even after multiple washes, making them ideal for custom apparel printing.

Can DTF transfers be applied to various fabric types?

Yes, DTF transfers are versatile and can be applied to a wide range of fabrics, including cotton, polyester, and blends. This makes them suitable for diverse apparel types.

What advancements are currently transforming DTF printing technology?

Recent advancements in DTF printing include high-speed production capabilities, the development of eco-friendly inks, and sophisticated color management software that enhances print quality by ensuring precise color matching.

Why should businesses choose DTF transfers over other printing methods?

Businesses should choose DTF transfers for their versatility, high-quality output, and cost-effectiveness, especially for small runs. This modern print technology provides bright, long-lasting designs without the high setup costs associated with traditional methods.

| Key Points | |

|---|---|

| Definition of DTF Transfers | A technique that prints designs on special film applied to fabric using heat, allowing for faster and cost-effective production. |

| Printing Methodology | All colors are printed in one go, reducing time and labor compared to traditional methods. |

| Ink Technology | High-quality inks ensure durability and vibrancy, with new eco-friendly options available. |

| Adhesive Powder Application | Bonds the ink to the film during heating, influencing the transfer’s performance on various fabrics. |

| Curing Process | Solidifies the bond for durability through innovative solutions that enhance efficiency. |

| Heat Press Techniques | Requires accuracy in temperature and time for quality transfer, with emerging technologies to automate this step. |

| Technological Advancements | Includes high-speed production and eco-friendly solutions to meet market demand. |

| Market Demand | Rising popularity exemplified by companies like Sam’s DTF Transfers catering to varied clientele. |

| Benefits of DTF Transfers | Versatility, high quality, and cost-effectiveness for small runs make DTF favorable over traditional methods. |

Summary

DTF transfers are revolutionizing the custom printing industry with their innovative techniques and advanced technology. This printing method not only caters to a variety of fabric types, offering exceptional print quality that endures over time, but it also provides a cost-effective solution for both small and large print runs. As the demand for DTF transfers grows, understanding their processes and benefits will empower businesses and individuals to create high-quality customized apparel that resonates with consumers. With ongoing advancements in technology and eco-friendly practices, the future of DTF transfers looks promising and full of potential for those looking to enhance their creative offerings.