DTF transfers have emerged as a game-changer in the world of DIY custom apparel, introducing a dynamic approach to garment customization that combines ease with high-quality results. Utilizing Direct-to-Film technology, this innovative method allows enthusiasts and businesses alike to create vivid designs that can be effortlessly applied onto a wide range of fabrics. As the demand for personalized attire surges, DTF printing stands out for its cost-effectiveness and ability to cater to small production runs, making it an ideal choice for budding entrepreneurs. Additionally, its sustainable printing solutions resonate with eco-conscious consumers who prioritize environmentally friendly practices in their purchasing decisions. In this brief overview, we will delve into the comprehensive benefits and future potential of DTF transfers, shining light on this transformative technique in custom garment printing.

Direct-to-Film technology, often referred to as DTF prints, is revolutionizing the custom apparel landscape with its user-friendly application and remarkable design capabilities. This innovative technique allows creators to easily transfer intricate graphics onto textiles, providing a versatile solution for both small-scale producers and passionate DIYers. As the trend of personalized fashion gains momentum, many are seeking out these custom garment printing methods that prioritize simplicity and quality. The rise in popularity of DTF transfers not only streamlines the design process but also aligns with contemporary values, including the demand for sustainable printing solutions. In exploring the benefits of this technology, we uncover how it is setting new standards in the manufacturing of unique clothing and accessories.

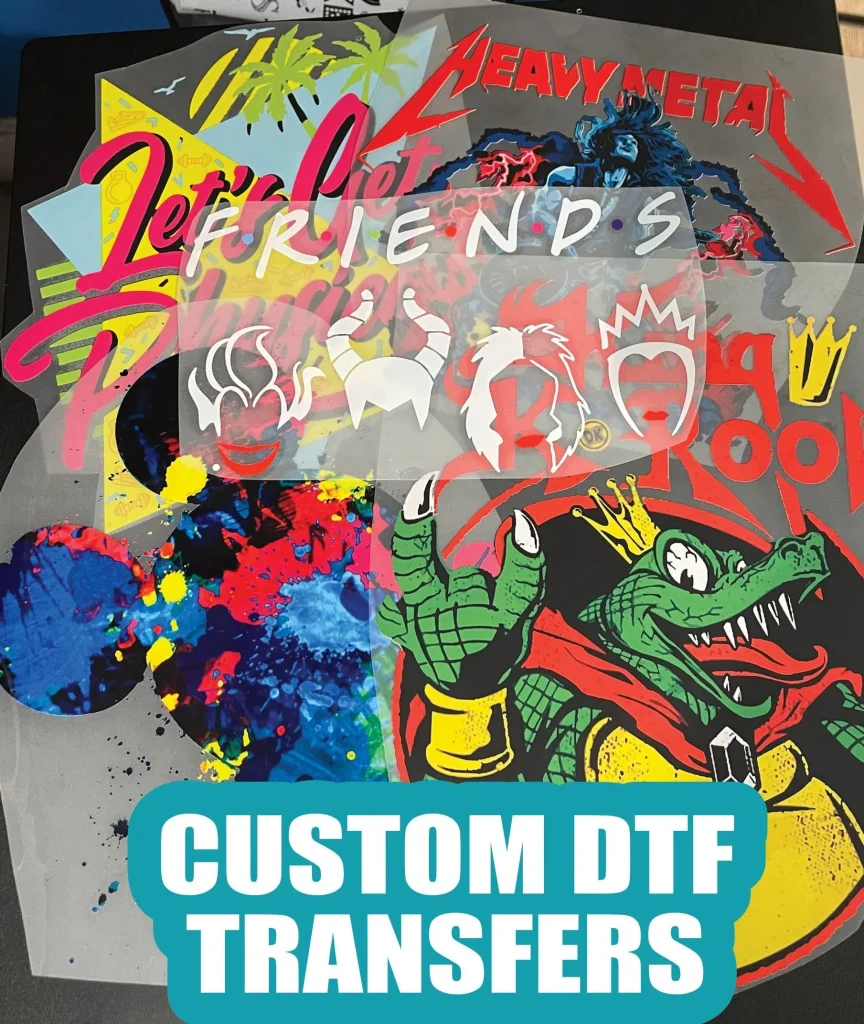

Understanding DTF Transfers and Their Impact on Custom Apparel

DTF transfers, or Direct-to-Film transfers, are changing the game in the realm of DIY custom apparel. This innovative printing method enables creators to produce intricate designs with vibrant colors directly onto various types of fabrics. The process involves printing graphics onto a special film, which is then heat-pressed onto garments. This technique stands out for its simplicity, allowing both enthusiasts and small business owners to create professional-grade apparel without the complexity and costs associated with traditional methods.

In recent years, as the demand for personalized clothing has surged, DTF transfers have risen to prominence. The versatility of DTF printing means it can be applied to a wide range of materials, including cotton, polyester, and blends, making it suitable for countless applications—from custom t-shirts to unique tote bags. As makers embrace this technology, the landscape of custom garment printing is rapidly evolving, reflecting the growing trend of self-expression through personalized fashion.

The Evolution of DTF Technology and Print Quality

One of the key aspects driving the adoption of DTF transfers is the remarkable evolution of printing technology. Advances in DTF ink formulations and transfer films have significantly improved the overall quality of prints. Innovations have led to enhanced durability, allowing designs to withstand numerous washes without fading or peeling. This level of resilience is crucial for both DIY enthusiasts wanting to create long-lasting pieces and businesses relying on high-quality products to satisfy their customers.

Moreover, the enhanced color vibrancy of DTF prints captivates audiences with stunning visuals that are hard to replicate with traditional printing methods. This technological leap means that small-scale operations can compete with larger brands, offering unique, high-quality designs that meet consumer expectations. As print capabilities continue to improve, the future of custom garment printing through DTF technology looks promising and filled with potential.

Cost-Efficiency of DTF Printing for Small Businesses

One significant advantage of using DTF transfers is the cost-effectiveness that they offer to small businesses. Unlike traditional screen printing, which often requires substantial investments for setup and bulk orders, DTF printing allows entrepreneurs to take a print-on-demand approach. This flexibility means that they can produce items as needed, significantly reducing inventory costs and financial risks associated with unsold products.

Furthermore, the accessibility of DTF printers and materials has lowered the barrier to entry for aspiring designers and small business owners. With fewer initial costs, it becomes easier to explore the custom apparel market without the fear of high financial stakes. This affordability is a game-changer, supporting a generation of creators who wish to bring their artistic visions to life without burdensome expenses.

DTF Transfers as Sustainable Printing Solutions

As sustainability becomes a core value for consumers, DTF transfers are positioned as a responsible alternative to traditional printing techniques. The increasing availability of eco-friendly inks and recyclable transfer films means that creators can embrace practices that align with a greener mindset. This environmentally conscious approach appeals to a growing demographic that prioritizes sustainability when making purchasing decisions regarding apparel.

By adopting DTF technology, businesses can showcase their commitment to sustainable practices. Not only does this enhance brand reputation, but it also attracts customers who are actively seeking ethical alternatives in fashion. As consumers become more aware of environmental impacts, DTF transfers represent an opportunity for businesses to lead the way in sustainable custom apparel production.

Building a Thriving DTF Community for Knowledge Sharing

The rise of DTF transfers has fostered the development of a passionate and supportive community. Online forums, social media groups, and dedicated platforms have emerged, allowing users to share tips, tricks, and best practices. This collaborative environment enables both newcomers and seasoned creators to learn from each other, enhancing the overall experience of working with DTF technology.

In addition, this community-driven knowledge sharing sparks innovation within the DTF space. Users can experiment with new techniques and designs, pushing the boundaries of what is possible with custom garment printing. As individuals hone their skills, the thriving DTF community becomes a catalyst for creativity and growth in the DIY custom apparel industry.

The Future of DTF Transfers in an Expanding Market

Looking ahead, the future of DTF transfers appears bright, with significant potential for growth in the custom apparel market. As consumer preferences shift towards personalization, more individuals are turning to DIY solutions. The rise of eCommerce platforms that support small-batch orders means DTF users can easily reach a wider audience and showcase their unique designs without the need for large production runs.

Additionally, industry experts predict that as technology advances, DTF printing will continue to integrate innovative features and processes. This ongoing development will not only enhance user experience but also democratize apparel production, expanding access for a broader range of creators. The path ahead for DTF transfers is promising, indicating a future where personalized fashion becomes the norm, allowing for greater self-expression and creativity.

Frequently Asked Questions

What are DTF Transfers and how do they work in DIY custom apparel?

DTF Transfers, or Direct-to-Film transfers, are a modern printing technique that allows designers to create vibrant and detailed prints on various fabrics. This method involves printing designs onto a special film and then transferring them onto garments using heat and pressure. It is an ideal option for DIY custom apparel, as it simplifies the customization process compared to traditional printing methods.

What are the benefits of using DTF printing for custom garment printing?

DTF printing provides several benefits for custom garment printing, including cost-effectiveness, ease of use, and vibrant print quality. It enables small businesses and DIY enthusiasts to create high-quality designs on demand without the need for bulk orders. Additionally, the durability and color accuracy of DTF transfers make them a preferred choice for custom apparel.

How does Direct-to-Film technology compare to traditional screen printing?

Direct-to-Film technology differs significantly from traditional screen printing in terms of setup and flexibility. DTF transfers require less preparation and allow for on-demand printing, making it cost-effective for small batches. Unlike screen printing, which can involve complicated setups for each design, DTF offers greater versatility and quicker turnaround times for custom apparel.

Is DTF printing an environmentally friendly option for custom apparel?

Yes, DTF printing is considered a sustainable printing solution because it uses environmentally friendly inks and recyclable films. Compared to conventional printing methods, DTF technology typically has a reduced environmental impact, making it an increasingly popular choice among eco-conscious consumers in the custom garment printing market.

How can I get started with DIY custom apparel using DTF transfers?

To get started with DIY custom apparel using DTF transfers, you will need a DTF printer, compatible films, and inks. First, design your artwork, print it onto the DTF film, and use a heat press to transfer it onto your apparel. Many online communities offer tutorials and support to help beginners navigate the DTF transfer process effectively.

What trends are emerging in the future of DTF transfers and custom apparel?

Emerging trends in DTF transfers include advancements in printing technology that enhance print quality and user experience. The rise of eCommerce platforms focused on custom apparel is also driving the demand for personalized items. As more individuals seek unique self-expression through DIY fashion, the DTF transfer market is poised for significant growth and innovation.

| Key Advantages | Details |

|---|---|

| Rising Popularity | DTF transfers provide a simple print-on-film process that allows for colorful designs on various fabrics. They are easier and less costly than traditional methods. |

| Cost-Effective Solutions | DTF printing requires lower investment costs, ideal for entrepreneurs. It supports print-on-demand, which aligns with the eCommerce trend for personalized products. |

| Quality Improvements | Recent advancements in DTF ink and film technology have improved durability and color accuracy, ensuring longer-lasting designs that remain vibrant after washes. |

| Environmental Impact | DTF printing utilizes eco-friendly inks and recyclable films, making it a more sustainable option compared to traditional printing methods. |

| Supportive Community | The growth of DTF has fostered a strong community for users to share experiences and ideas, enhancing creativity and support for newcomers. |

Summary

DTF Transfers have revolutionized the DIY custom apparel landscape, offering enthusiasts and businesses alike a vibrant, cost-effective, and eco-friendly means of creating unique clothing. By leveraging modern technology, this printing method provides not only superior print quality but also supports a community eager for innovation and creativity. As customization continues to captivate consumers, DTF Transfers are set to dominate the market, paving the way for an exciting future in personalized fashion.