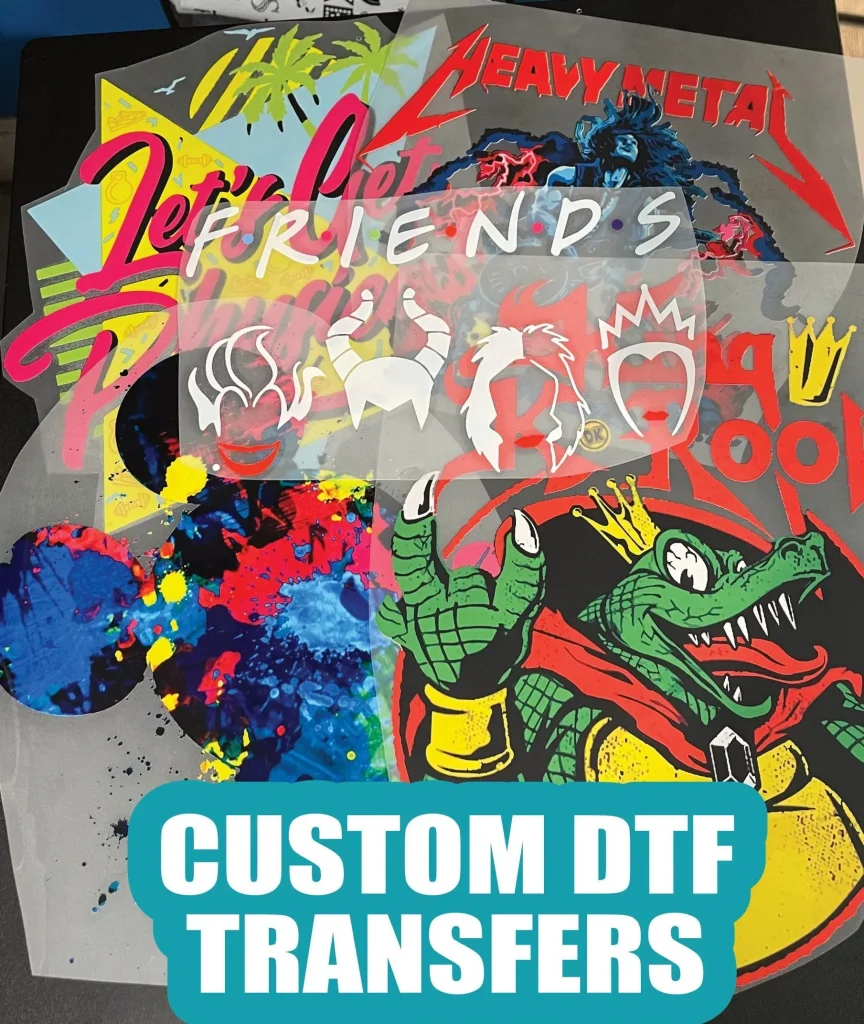

In the dynamic landscape of custom apparel printing, DTF transfers, or Direct-to-Film transfers, have emerged as a game-changing technology that simplifies the process of transferring intricate designs onto garments. Unlike conventional printing methods, DTF printing utilizes revolutionary techniques that allow vibrant, water-based inks to be printed onto special PET films, making it suitable for a variety of fabrics, including both light and dark options. This modern DTF technology not only enhances color vibrancy but also supports detailed designs, catering to the growing demand for personalized apparel. As businesses continue to seek efficient and high-quality printing solutions, understanding the DTF printing process becomes essential for maximizing production capabilities and meeting customer expectations. This guide aims to delve into everything you need to know about DTF transfers, including their advantages, necessary equipment, and trends shaping the future of apparel printing.

Exploring alternatives to traditional printing methods, the realm of Direct-to-Film transfers enhances the way designs are applied to textiles, offering an exciting blend of innovation and creativity. Known as DTF printing, this technique is revolutionizing the custom garment sector by enabling printers to achieve vivid designs with remarkable detail on a variety of fabric types. By employing advanced DTF technology, the printing process has become more accessible and efficient, paving the way for businesses to cater to individual customer preferences with ease. This overview not only highlights the benefits of DTF transfers but also provides insights into the current market trends, equipment, and techniques that define modern custom apparel printing. As the demand for custom designs continues to surge, DTF methods are quickly becoming essential for any serious printer.

Understanding the DTF Printing Process

The DTF printing process is a remarkable advancement in textile printing that allows for seamless design application onto a range of fabrics. This technique begins with a specially formulated PET film, where intricate designs are printed using vibrant water-based inks. Unlike traditional methods that require extensive setup for each print, DTF technology simplifies the procedure by enabling printers to generate high-quality transfers with remarkable detail and color vibrancy. After printing, a hot-melt adhesive powder is applied and heated, creating a strong bond that ensures longevity and durability of the graphic on the fabric.

This innovative method opens up new possibilities for custom apparel printing. Because DTF transfers do not require a white underbase, they can be applied directly to dark fabrics, which is a game-changer for printers aiming to expand their product offerings. The DTF printing process is not only efficient but also cost-effective, reducing the overall material consumption and waste compared to other printing methods. As such, understanding this process can set businesses apart in a competitive market.

Benefits of Using DTF Transfers for Custom Apparel

DTF transfers offer numerous benefits that make them an ideal choice for custom apparel printing. One of the key advantages is the incredible detail and vibrancy that DTF printing achieves. The high-quality inks used in this process allow for intricate designs and a wide range of colors, ensuring that every custom print stands out. Furthermore, the durability of DTF transfers ensures that the prints withstand multiple washes without fading or peeling, offering excellent value to customers.

Another significant benefit is the versatility of DTF transfers. These transfers can be applied to various fabrics, including cotton, polyester, and blends. This adaptability means that apparel brands can cater to diverse customer preferences, creating unique and personalized garments. Additionally, the simplicity of the DTF printing process enables quick turnaround times for orders, making it a practical choice for businesses looking to meet the growing demand for custom fashion.

DTF Equipment and Materials: What You Need to Get Started

To successfully implement DTF printing, investing in the right equipment and materials is essential. A high-quality DTF printer is pivotal; brands like Epson and Roland are recognized for their outstanding performance and vibrant output. These printers specifically cater to the requirements of DTF printing and ensure that designs are reproduced with precision and clarity. Alongside the printer, a reliable heat press machine is crucial for applying the transfers correctly, ensuring uniform heat distribution for the best adhesion.

Additionally, the choice of materials plays a significant role in the quality of the final product. Using specialized PET films and high-grade adhesive powders can dramatically affect the printed design’s performance. Businesses should source their supplies from reputable vendors to avoid common issues like peeling, fading, or inconsistent print quality. By assembling the right toolkit for DTF printing, companies can enhance their production capabilities and deliver exceptional products to their clientele.

Current Trends Shaping DTF Technology

The landscape of DTF technology is evolving rapidly as it gains popularity in the textile printing industry. One major trend is the increasing demand for custom apparel, fueled by consumer interest in personalized fashion. As people seek unique designs, companies are embracing DTF printing for its flexibility and ability to produce quick, high-quality custom orders. This trend reflects a broader shift in consumer behavior towards customization and personalization in various markets.

Another notable trend is the growing emphasis on sustainability within the DTF printing space. Innovations in eco-friendly inks and adhesives are becoming standard practice, catering to environmentally conscious consumers who are increasingly mindful of their purchases. Brands that adopt sustainable practices not only appeal to this demographic but also position themselves as leaders in responsible manufacturing in the competitive apparel market. As more companies integrate sustainable practices into their DTF printing processes, the industry itself is likely to experience significant growth.

Overcoming Challenges in DTF Printing

Despite the advantages of DTF transfers, several challenges need to be addressed to ensure optimal results. Quality control is a paramount concern, as using inferior inks or subpar films can lead to issues such as peeling or fading of prints over time. Businesses must implement stringent quality checks and choose high-quality materials to uphold their reputation for superior craftsmanship. Understanding the properties of different substrates is also critical to achieving the best results in DTF printing.

Additionally, the technical settings required for each fabric type can vary greatly. It’s essential for printers to experiment with temperature and pressure settings to find the ideal combination for different materials. As printers navigate these challenges, they should invest in ongoing education and training to stay informed about best practices in DTF technology. This continuous improvement can facilitate better outcomes and position businesses for success in an increasingly competitive market.

Recent Developments in DTF Printing Technology

The future of DTF printing technology is bright, with continuous advancements aimed at enhancing efficiency and output quality. Companies are focusing on refining ink formulations, developing products that not only provide superior adhesion and color vibrancy but also prioritize environmental friendliness. This innovation is crucial as the industry shifts towards more sustainable practices, ensuring that DTF production meets modern consumer demands.

Furthermore, the capabilities of newer DTF printers are expanding alongside these advancements. Enhanced precision and faster printing speeds contribute to greater productivity in print shops, allowing businesses to scale operations without compromising on quality. By staying informed about these technological improvements, companies can leverage new tools and techniques to optimize their DTF printing processes and maintain a competitive edge in the custom apparel industry.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct-to-Film transfers, involve printing designs onto specialized PET film using a DTF printer with vibrant water-based inks. After printing, a hot-melt adhesive powder is applied, and through a heating process, the design bonds securely to the fabric, allowing for intricate transfers onto garments.

What printer is best for DTF printing?

When choosing a printer for DTF printing, brands like Epson and Roland are highly regarded for their high-quality DTF printers. These printers offer vibrant print results and reliable performance, essential for producing detailed and colorful DTF transfers.

Can DTF printing be used on all types of fabrics?

Yes, DTF printing is versatile and can be used on various fabrics, including cotton, polyester, and blends. This flexibility allows businesses to create custom apparel with DTF Transfers that cater to a wide range of customer preferences.

What are the advantages of using DTF Transfers for custom apparel?

DTF Transfers provide numerous advantages, including high detail and color vibrancy, compatibility with various fabrics, efficiency for small batch orders, and the elimination of the need for a white underbase, making it suitable for dark fabrics.

How do I ensure quality control in DTF printing?

Quality control in DTF printing involves using high-quality inks and films to prevent issues like peeling and fading. It is also important to carefully adjust settings for different materials, ensuring optimal temperature and pressure during the transfer process.

What are the current trends in DTF technology?

Current trends in DTF technology include an increased demand for custom apparel, a focus on sustainable printing practices using eco-friendly inks, and a rise in educational resources like workshops and tutorials to help newcomers excel in DTF printing.

| Key Point | Details |

|---|---|

| What are DTF Transfers? | DTF transfers involve printing designs on PET film using water-based inks, allowing intricate designs to be applied to various fabrics without needing a white underbase. |

| Advantages | 1. High detail and color vibrancy; 2. Versatile for different fabrics; 3. Efficient for small batches; 4. No need for a white underbase. |

| Equipment Needed | DTF Printer, Heat Press Machine, Specialized Films and Adhesives are essential for effective DTF printing. |

| Current Industry Trends | Increase in demand for custom apparel, sustainable practices, and a surge in educational resources. |

| Challenges | Quality control issues due to lower quality inks or films and the need for precise material settings for different fabrics. |

| Recent Developments | Advancements in ink formulations and enhanced printer capabilities aim to improve efficiency and quality. |

Summary

DTF Transfers play a pivotal role in transforming the landscape of textile printing. This innovative method allows for exceptional detail, vibrancy, and versatility across various fabric types. As demand for personalized apparel grows, businesses that embrace DTF printing can effectively meet the evolving needs of consumers. With ongoing advancements in technology and materials, DTF Transfers not only enhance print quality but also align with sustainable practices, making them a vital component for businesses aiming to thrive in the dynamic custom apparel market.