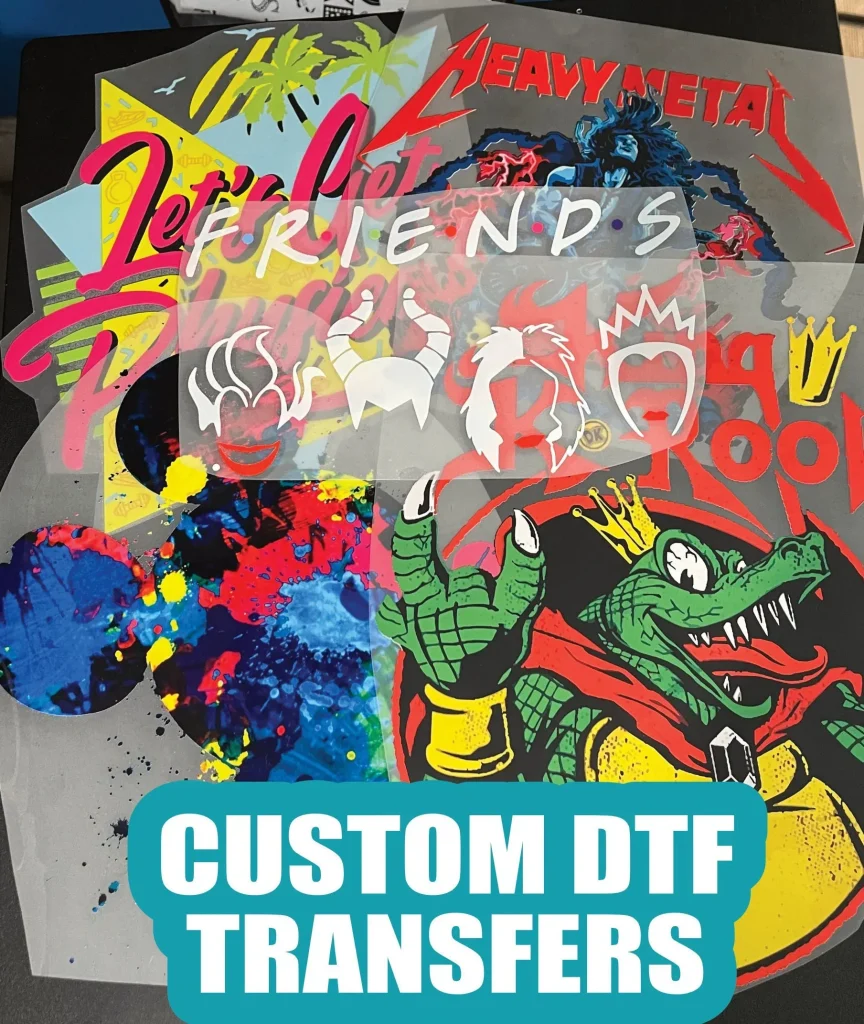

DTF transfers, or Direct to Film transfers, have rapidly gained popularity in the realm of custom apparel printing, revolutionizing the way designs are applied to fabrics. Leveraging the innovative DTF printing process, this technique allows for vibrant, intricate designs to be printed on a transparent film, which can then be easily transferred onto various materials. One of the key benefits of DTF printing is its versatility, making it an excellent choice for both small business owners seeking to expand their product line and DIY enthusiasts looking to unleash their creativity. With DTF transfer kits now readily available, anyone can explore the world of custom printing from the comfort of their home. In this guide, we will delve into the multifaceted advantages of DTF transfers, ensuring you have all the information needed to make the most of this remarkable technology.

Direct to Film printing, often referred to as DTF print technology, has emerged as a game changer in the custom apparel industry. This innovative approach to printing allows for high-quality graphics to be transferred directly onto a variety of fabrics, from t-shirts to bags, thereby enhancing the overall customization experience. The DTF printing benefits are quite significant, particularly for those engaged in small-scale production or entrepreneurship. Additionally, the availability of DTF transfer kits has made it easier than ever for creatives and businesses alike to get started with this cutting-edge technique. In this exploration, we will uncover the essential elements of DTF printing and how to effectively utilize this brilliant method.

Understanding DTF Transfers: The Future of Custom Apparel Printing

Direct to Film (DTF) transfers have revolutionized the garment printing industry, allowing for stunning designs to be effortlessly applied to a wide array of fabrics. This innovative technique uses specialized water-based inks to print directly onto a transparent film, which is then adhered to the fabric through a unique heating process. This not only enhances color vibrancy but also provides durability and longevity, making it a favorite among custom apparel creators.

One of the significant advantages of DTF transfers is its versatility; it can be applied to various materials, ranging from cotton to blends, making it ideal for diverse apparel options. As businesses and DIY enthusiasts increasingly embrace DTF technology, the ability to produce intricate designs that stand out has become more accessible than ever. This transformative method is reshaping the future of custom printing, offering both affordability and high-quality outputs.

The DTF Printing Process Explained

The DTF printing process is a multi-step operation that is integral to achieving high-definition prints on fabric. It begins with design preparation, where the intended graphics must be meticulously created and formatted using graphic design software. Formats such as PNG and TIFF are commonly utilized to ensure compatibility with the DTF printer. Once the design is ready, it transitions into the printing phase, where specialized DTF inks are applied to the film, ensuring a vibrant color palette.

Following the printing step, a powder adhesive is applied to the wet ink to facilitate a strong bond during the heat transfer phase. This series of processes requires precision and attention to detail. The final step involves a heat press, which activates the adhesive and secures the print onto the fabric. This method enables designs to maintain their intricate details and ensures that they withstand the test of time, greatly enhancing the wearer’s experience.

Key Benefits of DTF Transfers for Businesses

There are numerous benefits associated with DTF transfers that make them an appealing choice for businesses. Firstly, the vibrant colors produced through the DTF printing process create a striking visual impact that captivates potential customers. This ability to create eye-catching designs is particularly beneficial in a competitive market where standing out is essential.

Additionally, DTF transfers require significantly lower startup costs than traditional screen printing methods, making them an excellent option for small business owners and hobbyists alike. The flexibility in production runs also allows customization for both small batches and large orders, catering to the dynamic needs of any merchandise strategy. This blend of affordability, quality, and versatility positions DTF printing as a game-changer in the custom apparel sector.

Exploring the Limitations of DTF Transfers

While DTF transfers offer numerous advantages, it’s essential to consider some potential drawbacks. One of the most commonly mentioned concerns is the feel of the final product. Users have commented that DTF prints can sometimes feel harsher on the fabric compared to prints from Direct-to-Garment (DTG) methods. This tactile difference can be a critical factor for certain applications, particularly in clothing where touch and comfort are paramount.

Moreover, although the initial setup and equipment costs may deter some newcomers, the long-term benefits often outweigh these challenges. Investing in high-quality DTF printers and supplies can lead to improved production quality and increased customer satisfaction. Understanding these limitations is crucial for anyone looking to integrate DTF printing into their business model effectively.

Current Trends in DTF Printing Technology

As DTF printing technology continues to evolve, several key trends are shaping the landscape. A notable trend is the rise in DIY DTF transfer kits, which provide aspiring entrepreneurs with tools and materials to create custom designs from the comfort of their homes. These all-in-one kits typically include a DTF printer, film, powders, and even beginner-friendly tutorials, making it easier for individuals to start their printing journeys.

Additionally, advances in DTF printer technology have made it more accessible for small businesses to incorporate high-quality printing into their offerings. The latest models boast improved print speeds and quality, allowing users to streamline their production processes without sacrificing output. Keeping abreast of these trends will enable businesses to leverage the full potential of DTF printing and stay competitive in an ever-evolving market.

Maximizing Your DTF Printing Experience with the Right Accessories

To optimize the DTF printing experience, investing in the right accessories is crucial. DTF transfer kits typically include essential items such as the printer, film, and adhesives, but accessories like heat presses and vector graphic design programs can further enhance your results. A high-quality heat press with adjustable temperature settings ensures that transfers adhere properly to various fabric types, which can make a significant difference in the final product’s durability and quality.

Furthermore, familiarity with vector graphic design programs can expand your creative possibilities when designing custom apparel. Incorporating advanced software can help you elevate your designs, allowing for greater customization that appeals to your target audience. By combining quality DTF transfer kits with the right accessories, you can unlock new creative horizons and maximize the potential of your custom printing business.

Frequently Asked Questions

What is the DTF printing process for creating custom apparel?

The DTF printing process involves preparing a design in graphic software, printing it onto a transparent film using DTF inks, applying a powder adhesive, and then using a heat press to transfer the design onto various fabrics like cotton and polyester. This method allows for vibrant colors and intricate details in custom apparel.

What are the primary benefits of using DTF transfers for textile printing?

DTF transfers offer vibrant colors, compatibility with diverse materials, and lower startup costs compared to traditional methods. They are ideal for small and large production runs, making them a cost-effective choice for custom apparel and promotional items.

How do DTF transfer kits work for DIY printing projects?

DTF transfer kits typically include everything needed for DIY printing, such as a DTF printer, film, inks, and adhesives. These kits enable individuals to easily produce custom designs at home, catering to hobbyists and small business owners alike.

Can DTF transfers be used on multiple fabric types?

Yes, DTF transfers are compatible with a wide range of materials including cotton, polyester, and fabric blends. This versatility makes DTF printing suitable for various custom apparel products like t-shirts, sweatshirts, and tote bags.

Are there any downsides to using DTF printing technology?

While DTF transfers are known for their durability and vibrant results, they may have a harder feel compared to direct-to-garment prints. Additionally, the initial investment in DTF printers and supplies can be significant, which may pose a challenge for new users.

What recent trends are emerging in the DTF printing industry?

Recent trends include the rise of DIY DTF transfer kits, increased availability of online resources for learning DTF printing techniques, and advancements in printing technology that enhance speed and quality, making DTF more accessible to small businesses.

| Key Point | Description |

|---|---|

| What are DTF Transfers? | DTF transfers are a printing method that transfers designs onto fabrics using a special film and environmentally friendly inks. |

| The DTF Printing Process | The process includes design preparation, printing on film, applying adhesive, and heat transferring the design onto fabrics. |

| Advantages of DTF Transfers | DTF transfers offer vibrant colors, compatibility with various materials, lower startup costs, and flexibility in production runs. |

| Disadvantages of DTF Transfers | They may feel harder compared to DTG prints and have higher initial equipment costs. |

| Applications of DTF Transfers | Used for custom apparel, branded merchandise, and decorative items. |

| Recent Trends in DTF Printing | Emerging trends include DIY kits, increased online educational resources, and advancements in printing technology. |

Summary

DTF transfers are revolutionizing the printing industry by providing a flexible solution for custom apparel and promotions. This innovative method allows vibrant designs to be applied to a wide range of fabrics, making it increasingly popular among small businesses and DIY enthusiasts. As the technology continues to evolve and trends shift towards accessibility and education, DTF transfers are poised to become an essential tool for anyone looking to make their mark in the world of printing. Understanding both the benefits and challenges of DTF transfers will empower you to effectively navigate this dynamic marketplace.