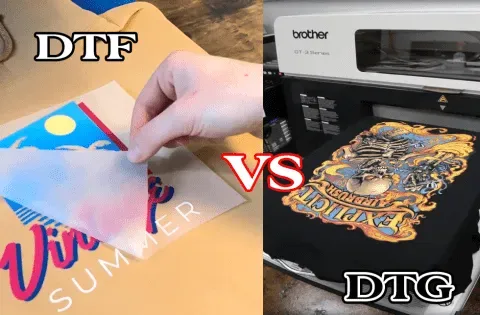

In the rapidly evolving realm of fabric printing, understanding the differences between DTF vs. DTG is essential for anyone looking to adopt the latest printing technologies. Direct to Film (DTF) and Direct to Garment (DTG) printing represent two of the most sought-after methods, each boasting distinct advantages that cater to different consumer needs. As e-commerce flourishes and personalized apparel takes center stage, businesses must evaluate which of these printing methods aligns with their production goals and market trends. This article breaks down both DTF printing and DTG printing, highlighting their unique characteristics, applications, and environmental impacts. Dive in to uncover which fabric printing technology may best suit your operational needs and design ambitions.

When exploring fabric printing technologies, the terms Direct to Film (DTF) and Direct to Garment (DTG) come prominently into play. These innovative printing methods are revolutionizing how businesses print designs onto apparel, each offering unique features and catering to different fabric types. DTF, often recognized for its versatility and efficiency, contrasts with DTG’s ability to deliver richly detailed graphics on cotton fabrics. As the demand for customized clothing continues to grow, understanding these direct printing options will empower brands to make informed decisions. Join us as we examine the strengths and weaknesses of these popular printing techniques in detail.

The Rise of DTF Printing in Today’s Market

DTF printing is gaining traction in the fabric printing industry as more businesses recognize its advantages over traditional methods. With its ability to apply vibrant designs to a wide range of materials, DTF offers versatility that is essential for meeting diverse customer demands. This technology is particularly appealing to small and medium-sized enterprises due to its lower production costs and quicker turnaround times. As these businesses seek ways to optimize operations and minimize waste, DTF printing is positioned as a frontrunner in the current printing landscape.

Recent trends indicate a substantial shift in market preferences towards DTF printing, particularly in sectors where speed and efficiency are paramount. Surveys show that users favor DTF for its ease of use, allowing for less training time and a straightforward operational process. Such benefits enable companies to increase their output while maintaining the quality standards expected by consumers, establishing DTF as a viable option for businesses looking to adapt in a competitive environment.

Advantages and Disadvantages of DTG Printing

Direct to Garment (DTG) printing has established itself as a go-to choice for companies focused on intricate designs and high-quality outputs. One of the main advantages of DTG is its capability to produce highly detailed graphics with vibrant colors, especially on cotton fabrics. This quality makes it ideal for personalized apparel and artistic designs, where customers prioritize the aesthetic appeal and tactile experience of their garments.

However, despite its undeniable qualities, DTG printing has notable drawbacks. The initial investment for DTG equipment can be prohibitively high for smaller operations, and the slow production speed poses challenges for fulfilling large orders. Additionally, the pre-treatment processes required for fabric can generate significant waste and complicate the workflow, leaving businesses torn between the desired quality and the practicalities of large-scale production.

Comparing DTF vs. DTG: Which Method is More Efficient?

When evaluating DTF vs. DTG, efficiency often emerges as a key differentiator between the two methods. DTF printing tends to offer quicker setups and the ability to process larger volumes, making it a more efficient option for businesses looking to optimize production. The reduction in operational steps and lower material waste contribute to a streamlined process, translating into increased profitability for print shops. This efficiency is especially appealing in fast-paced environments where meeting tight deadlines is essential.

On the other hand, while DTG may provide exceptional quality, the slower production rate can be a significant hurdle. Businesses focused on large-scale orders may find that DTG can hinder their ability to compete effectively in the market. Thus, the efficiency comparison highlights a crucial consideration for any business weighing the merits of DTF against DTG—how much do speed and operational cost impact their specific printing needs?

User Preferences Trends in Fabric Printing Technologies

Recent survey data suggests a notable trend in user preferences within the fabric printing industry, particularly favoring DTF printing due to its practicality and cost-effectiveness. Print shop owners are increasingly opting for technologies that allow for maximum flexibility in terms of materials and production capabilities. DTF’s ability to print on various fabrics, including synthetics, broadens the scope for businesses to cater to diverse consumer tastes without the limitations inherent in DTG.

Conversely, there remains a segment of the market that holds DTG in high regard, especially among brands that prioritize intricate design work. Users of DTG express particular appreciation for the softness and quality of prints, especially when targeting luxury items. As such, user preferences reflect a balanced appreciation for both methods, emphasizing the importance of aligning technology choices with the specific needs of clientele.

Environmental Impact of DTF and DTG Printing

The environmental considerations surrounding printing methods are becoming increasingly central to discussions of sustainability in the fabric printing industry. DTF printing has been noted for its lower environmental footprint, thanks to innovations in ink technology that reduce waste and energy consumption. These advancements not only fulfill consumer demands for high-quality products but also align with the growing push for sustainable practices in manufacturing.

In contrast, DTG printing faces scrutiny over its pre-treatment processes and waste generation. While the quality of prints produced remains high, the environmental cost associated with traditional DTG methods raises concerns among eco-conscious consumers. Thus, as businesses navigate the complexities of choosing between DTF and DTG, the environmental impact is becoming a crucial factor guiding their decision-making process.

Future Outlook: DTF vs. DTG in the Evolving Market

As the fabric printing industry continues to evolve, the future outlook for DTF and DTG printing methods indicates an exciting landscape filled with opportunities for innovation. With DTF technology advancing rapidly, businesses are encouraged to stay tuned to emerging trends and improvements in ink formulations that enhance both quality and performance. This adaptability could make DTF even more appealing, enabling print providers to meet the ever-changing demands of consumers.

Meanwhile, DTG printing is not standing still; technological advancements may lead to solutions that address its current inefficiencies and environmental concerns. As the competitive landscape pushes for continual improvement, both DTF and DTG will likely evolve to offer enhanced features that cater to niche markets. Ultimately, the success for businesses may hinge on their ability to remain agile and responsive to these shifting dynamics within the fabric printing industry.

Frequently Asked Questions

What are the key differences between DTF printing and DTG printing?

DTF printing (Direct to Film) uses a specialized film to transfer designs onto garments, allowing for versatility across materials, including synthetics. In contrast, DTG printing (Direct to Garment) directly applies ink onto fabric, resulting in high-quality prints ideal for detailed designs, primarily on cotton. Both methods vary in production speed, costs, and fabric compatibility.

Which is more cost-effective, DTF printing or DTG printing?

Generally, DTF printing is considered more cost-effective than DTG printing. DTF typically has lower setup and production costs, making it appealing for businesses looking to optimize budget and efficiency. DTG printing, while capable of high-quality output, comes with higher initial investments and slower production times due to pre-treatment requirements.

What types of fabrics can be used with DTF printing versus DTG printing?

DTF printing excels with a wider range of fabrics, including synthetics, blends, and cotton, offering greater versatility. Conversely, DTG printing is best suited for natural fibers, particularly cotton, as the ink adheres better, providing vibrant colors and a soft hand feel. If you require multi-material printing, DTF may be the better choice.

Is DTF printing suitable for large volume orders compared to DTG printing?

Yes, DTF printing is highly suitable for large volume orders due to its quick setup times and efficient transfer process, allowing businesses to meet high demand with ease. In comparison, DTG printing can be slower due to the required pre-treatment of garments, making it less ideal for bulk orders.

How do print quality and design intricacy compare between DTF and DTG printing?

DTG printing generally offers superior print quality, especially for intricate designs and vibrant colors, as the ink penetrates the fabric. DTF printing, however, has made significant advancements in quality, and modern DTF inks can produce high-resolution graphics that rival DTG prints, though DTG is typically preferred for luxury applications.

What are the environmental impacts of DTF printing versus DTG printing?

Both DTF and DTG printing have environmental impacts, but DTF is gaining recognition for being more eco-friendly. Recent innovations in DTF inks have reduced waste and harmful emissions. DTG printing, while producing high-quality results, often involves more waste due to pre-treatment processes. Therefore, for businesses focusing on sustainability, DTF may be the preferable printing method.

| Aspect | DTF (Direct to Film) | DTG (Direct to Garment) |

|---|---|---|

| Definition | Prints designs onto a film which is then transferred to fabric using heat. | Prints directly onto the fabric using inkjet technology. |

| Advantages | – Versatile; works on a wide range of materials, including synthetics. – Faster setup and production efficiency. – Lower production costs. | – Offers high quality and detail suitable for intricate designs. – Produces vibrant colors with a soft feel. |

| Disadvantages | – Requires special films for transfer. – Potential learning curve for operators but generally easier than DTG. | – Higher initial setup costs. – Slower production speed due to pre-treatment processes. |

| Market Trends | Growing preference among small to medium businesses for affordability and quick production. | Brands focusing on high-quality, luxury products often favor this method despite costs. |

| Environmental Impact | More eco-friendly options emerging; reduced waste and harmful emissions expected. | Can generate significant waste; pre-treatment processes are resource-intensive. |

Summary

DTF vs. DTG is a compelling topic in the fabric printing landscape that explores two distinct methods with varying strengths. While DTF (Direct to Film) printing excels in versatility, cost-effectiveness, and environmental sustainability, DTG (Direct to Garment) printing shines with its high-quality output and suitability for intricate designs. The choice between DTF and DTG ultimately depends on the specific needs of a business, such as production volume, fabric types, and customer demands. Understanding these nuances allows print providers to make informed decisions, optimizing their technologies to cater to current market trends.