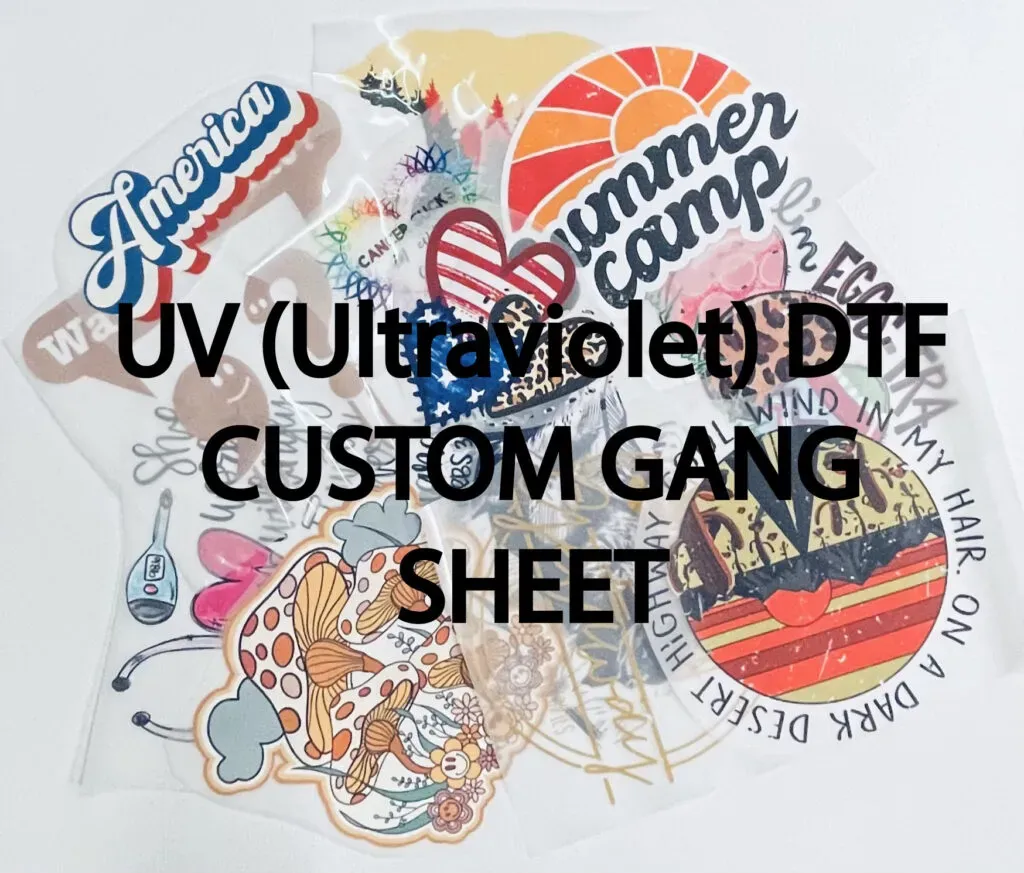

In the rapidly evolving world of printing, **UV DTF Gangheet** stands out as a revolutionary technique that combines the best features of innovation and efficiency. Unlike traditional printing methods, UV DTF printing utilizes ultraviolet light to instantly cure the ink on various surfaces, offering businesses a more versatile approach to production. As the demand for high-quality prints increases, this modern method is gaining traction, especially for printing intricate designs on diverse materials such as fabrics and plastics. Throughout this article, we will delve into the numerous benefits of UV DTF printing and compare it with established techniques like screen printing and digital printing. Whether you are a business owner or a printing enthusiast, understanding the nuances of UV DTF technology will empower you to make an informed choice for your printing needs.

Exploring the landscape of modern printing technology, we encounter what some might refer to as direct-to-film printing, an innovative branch of **digital printing** that has gained popularity among artists and businesses alike. This printing method, often compared to traditional **screen printing** and other legacy techniques, offers unparalleled flexibility and quality. Both hobbyists and professionals can harness the power of UV printing to achieve stunning results across various substrates. As we discuss alternatives to conventional printing practices, understanding UV DTF’s advantages will highlight its potential to transform the printing industry. Join us as we investigate this versatile printing method that is redefining expectations in the creative field.

Understanding UV DTF Gangheet

UV DTF Gangheet has become a buzzword in the printing community, often recognized for its innovative approach to producing high-quality prints. Unlike traditional printing methods, which can take significant time to set up and execute, UV DTF printing offers a streamlined process that utilizes ultraviolet light to cure ink instantly. This means that prints can be ready for use almost immediately after they have been created, which is a critical advantage for businesses and creators who need quick turnaround times.

Additionally, UV DTF technology is rapidly evolving, with advancements being made by various companies that specialize in printing equipment. The incorporation of UV DTF printers into workflows allows for greater flexibility, enabling users to experiment with different substrates such as wood, glass, and textiles. This versatility opens up a wealth of possibilities for custom solutions, appealing especially to those looking to create unique, high-value products.

The Advantages of UV Printing Over Traditional Methods

One of the primary advantages of UV printing, specifically UV DTF, is its ability to produce durable prints. Unlike traditional inks that may fade or wash away over time, UV cured inks create a strong bond with the substrate, ensuring longevity and a vibrant finish. For businesses that depend on the quality of their printed materials to represent their brand, this durability is a crucial factor in choosing UV printing over traditional methods like screen printing.

Furthermore, the efficiency of the UV printing process is remarkable compared to traditional printing techniques. For instance, in screen printing, inks require extended drying periods, which can delay production schedules. In contrast, UV DTF prints are instantly cured as they are made, which substantially reduces overall production times. As such, manufacturers and businesses can respond quickly to market demands, providing them with a competitive edge in a fast-paced environment.

Exploring the Versatility of UV DTF Printing

UV DTF printing stands out for its versatility across a range of applications. Where traditional printing methods might limit users to specific materials, UV DTF allows printers to adapt to various surfaces without compromising on quality. This aspect is especially valued by companies seeking to diversify their offerings; they can easily switch between printing on fabrics, plastics, and wood without the need for extensive reconfiguration.

This adaptability makes UV DTF printing a superior choice for custom projects, personalization, and short run prints. For example, businesses can offer tailored products like custom promotional items or unique apparel with intricate designs that traditional methods may not accommodate. The freedom to explore creative options makes UV DTF an excellent avenue for artists, brands, and companies eager to push the boundaries of conventional printing.

Traditional Printing: A Comparison of Cost Efficiency

When it comes to cost, traditional printing methods like screen printing have often been favored for large orders due to their scalability. The initial setup for screen printing might be lower, especially for high-volume jobs, where economies of scale can significantly reduce the cost per unit. This cost-effectiveness makes it an attractive option for businesses that regularly produce bulk items.

However, it’s essential to consider the long-term costs associated with traditional printing. While the upfront investment might be less, the longevity and durability of prints produced with UV DTF methods may ultimately lead to significant cost savings. The need for less frequent reprints, given the longevity of UV-curated inks, can offset the higher initial equipment costs, presenting a compelling case for UV DTF as a modern printing solution.

Advantages of Screen Printing in Specific Scenarios

Despite the rising popularity of UV DTF printing, traditional screen printing maintains a stronghold in specific scenarios, particularly in high-volume print runs. Businesses that require large quantities of uniform prints can benefit from the efficiency and reduced costs associated with bulk production through screen printing. Once the initial setup is complete, the per-unit costs drop significantly, making it the preferred choice for mass-produced items.

Moreover, screen printing provides an advantage in terms of color vibrancy and opacity, especially on darker materials. Many traditional printing enthusiasts swear by the richness of colors that can be achieved with screen printing, a quality that may sometimes be challenging to replicate with UV DTF processes. Therefore, knowing when to utilize screen printing amid the advancements of UV DTF is crucial for any business looking to balance quality and cost.

Making an Informed Choice: Factors to Consider

Choosing between UV DTF Gangheet and traditional printing methods involves several considerations that can impact your printing success. One critical factor is the volume of production you expect to handle. Businesses requiring high turnover and volume may find traditional printing methods more financially viable, given their efficiency in turning out large batches. Understanding your production needs will help dictate which method to pursue.

Another essential factor to consider is the type of media you’ll be using for your prints. If your projects involve unconventional materials or require a high degree of customization, UV DTF may be the superior choice. By carefully evaluating these factors, including media compatibility and your specific printing goals, you can make a more informed decision on which printing method aligns best with your operational needs.

Frequently Asked Questions

What are the advantages of UV DTF Gangheet compared to traditional printing methods?

UV DTF Gangheet offers several advantages over traditional printing methods, including enhanced versatility, durability, and efficiency. Unlike traditional printing like screen printing, which is often limited to specific substrates, UV DTF can print on a wide range of materials such as fabric, wood, and plastic. The UV curing process also ensures that prints are more durable and resistant to wear compared to ink from traditional printers.

How does UV DTF Gangheet improve on standard digital printing techniques?

UV DTF Gangheet enhances standard digital printing techniques by incorporating UV curing technology, which solidifies the ink almost instantly upon printing. This process allows for immediate handling and minimizes drying time compared to standard digital printing, providing an efficient solution for high-volume printing needs. Additionally, it expands the range of printable surfaces beyond what traditional digital printing can accommodate.

Is UV DTF printing cost-effective for large-scale projects compared to screen printing?

While UV DTF printing is incredibly versatile, it may not always be cost-effective for large-scale projects compared to traditional screen printing. Screen printing typically offers lower costs per unit due to economies of scale; however, UV DTF Gangheet can provide high-quality prints on a variety of substrates, making it suitable for custom orders and projects that require intricate designs.

What types of materials can I use with UV DTF Gangheet?

UV DTF Gangheet is known for its versatile printing capabilities and can successfully print on a wide range of materials. This includes textiles, wood, plastic, and even metal, distinguishing it from traditional methods like screen printing that often cater to specific media. The ability to print on unconventional surfaces makes UV DTF an attractive option for creative projects.

How does the durability of UV DTF prints compare to those made by traditional printing methods?

UV DTF prints are generally more durable than those produced by traditional printing methods. The UV curing process creates a strong adhesion to the substrate, resulting in prints that are highly resistant to fading, peeling, and wear over time. This contrasts with traditional inks that may not offer the same level of longevity, especially under exposure to elements.

What should I consider when choosing UV DTF Gangheet over traditional printing methods?

When choosing UV DTF Gangheet over traditional printing methods, consider factors such as your production volume, the types of materials you intend to print on, and your budget. UV DTF is particularly advantageous for projects requiring flexibility and quick turnaround times, whereas traditional methods may be better suited for large-volume orders where cost-effectiveness is essential.

| Aspect | UV DTF Printing | Traditional Printing Methods |

|---|---|---|

| Technology | Utilizes UV light for curing ink on various substrates | Includes methods like screen printing and DTG printing, established for decades. |

| Advantages | High versatility, durability, and quick turnaround | Cost-effective for large orders; simplicity in setup |

| Best Use Case | Ideal for intricate designs on diverse materials | Effective for high-volume production |

| Initial Investment | Higher due to advanced technology | Lower initial costs for setups |

Summary

UV DTF Gangheet offers a revolutionary approach to printing, with unmatched versatility and efficiency that benefits both businesses and hobbyists. The rise of UV DTF printing technology ensures vibrant and durable outputs, setting it apart from traditional printing methodologies. As you navigate the options for your printing needs, understanding the advantages and applications of UV DTF will empower you to choose the right method tailored to your creative projects. Embracing this innovation could unlock new avenues for artistic expression and production efficiency in your work.